Engine cooling system

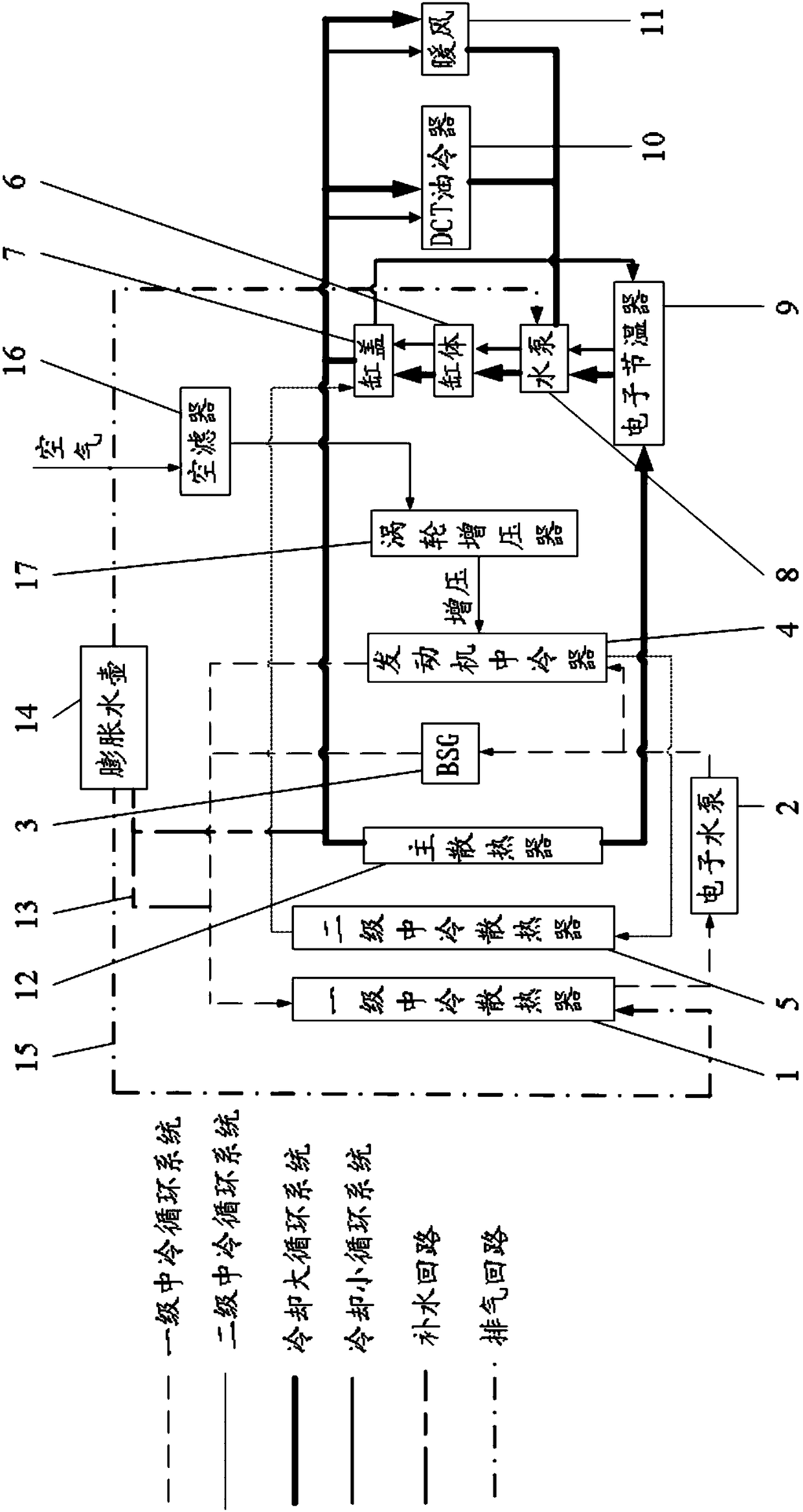

An engine cooling and engine technology, which is applied to engine cooling, engine components, combustion engines, etc., can solve the problems of low cooling efficiency, poor cooling stability, and increasing the content of nitrogen oxides in engine exhaust gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention are described in detail below, and examples of the embodiments are shown in the drawings, wherein the same or similar reference numerals denote the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0027] Definition of key components

[0028] BSG: (Belt Starter Generator) A belt starter generator system, which can realize engine start / stop function, energy recovery, auxiliary torque increase and other functions.

[0029] Electronic water pump: a motor-driven water pump that uses piezoelectric materials as a power device, which can realize electronic control from drive, and uses an electronic integrated system to control liquid transmission to achieve adjustability and accuracy of liquid transportation.

[0030] Main rad...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap