Axial force self-balancing vertical centrifugal pump

A vertical centrifugal and self-balancing technology, applied in non-variable displacement pumps, non-displacement pumps, radial flow pumps, etc., can solve problems such as excessive axial load and affecting service life, to offset self-weight, reduce Failure rate and effect of small axial load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

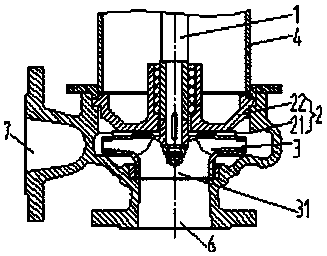

[0023] see figure 2 , an axial force self-balancing vertical centrifugal pump according to Embodiment 1 of the present invention, including a pump casing 2 and a vertical pump shaft 1, the upper end of the pump shaft 1 is connected to a motor (not shown in the figure), and the lower end extends into the pump casing 2 and connected with the impeller 3 in the pump casing 2 to drive the impeller 3 to rotate, the pump casing 2 includes a pump body 21 and a pump cover 22, the pump cover 22 is connected with a motor bracket 4 for placing the motor, The position where the pump shaft 1 passes through the pump cover 22 is provided with a connecting bearing 5 to increase the stability of the pump shaft 1 when it rotates. There are also two supports in the motor bracket 4 that are provided with connecting parts and are connected to the pump shaft 1 through bearings; The side of the cover 22 is provided with a water inlet 6, the water inlet 6 and the impeller 3 have a height difference i...

Embodiment 2

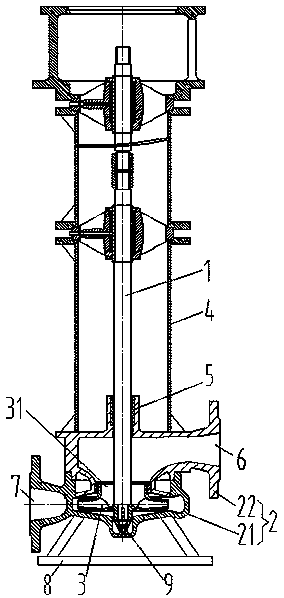

[0026] see image 3 The difference between Embodiment 2 and the axial force self-balancing vertical centrifugal pump in Embodiment 1 is that the axial force self-balancing vertical centrifugal pump in Embodiment 2 is a submerged pump. The whole pump casing 2 needs to be placed in the underwater operation, its water outlet 7 is connected to the upward water outlet pipe 71, its motor support 4 is a cylindrical structure, its pump cover 22 is a hollow ring structure, the inner cavity of the motor support 4 and the pump The hollow part of the cover 22 is connected, and the water inlet 6 is opened on the side wall of the motor bracket 4, and the water inlet 6 is also located on the impeller 3, so that the manufacture of the pump cover 22 is simpler; other similar effects will not be repeated; Sump pumps are also usually not provided with a base.

Embodiment 3

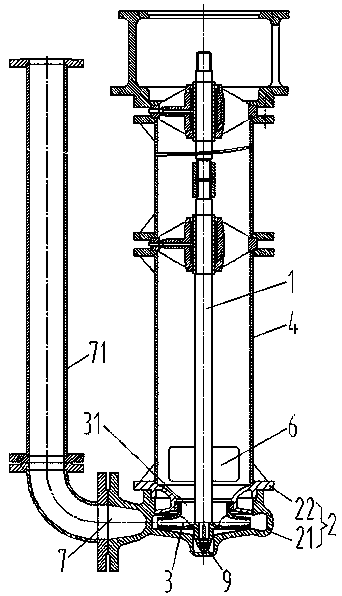

[0028] see Figure 4 , the third embodiment is a further optimized structure on the basis of the second embodiment, the lower end of the pump body 21 is still closed, the tail end of the pump shaft 1 continues to extend downwards and the extended shaft section is covered with a shaft sleeve 10, the shaft The upper end of the sleeve 10 abuts against the lower end of the impeller 3, and the lower end of the sleeve 10 is pressed upward by the impeller nut 9 threaded with the pump shaft 1; the outer side of the sleeve 10 is connected with the pump body 21 through the connecting bearing 5. In this way, although the middle part of the pump cover 22 is designed as a hollow structure for the passage of fluid, the pump cover 22 and the pump shaft 1 are not connected by bearings, but the shaft section of the pump shaft 1 below the impeller 3 is still connected to the pump by connecting the bearing 5. The pump body 21 of the shell 2 is kept connected, which can also ensure the rotation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com