Bearing seal cover and bearing sealing structure

A technology of bearing sealing and sealing cover, which is applied in the directions of connecting rod bearings, bearing components, shafts and bearings, etc., can solve the problem of the sealing cover losing its sealing function, and achieve the effect of simple structure, convenient disassembly and assembly, and avoidance of falling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

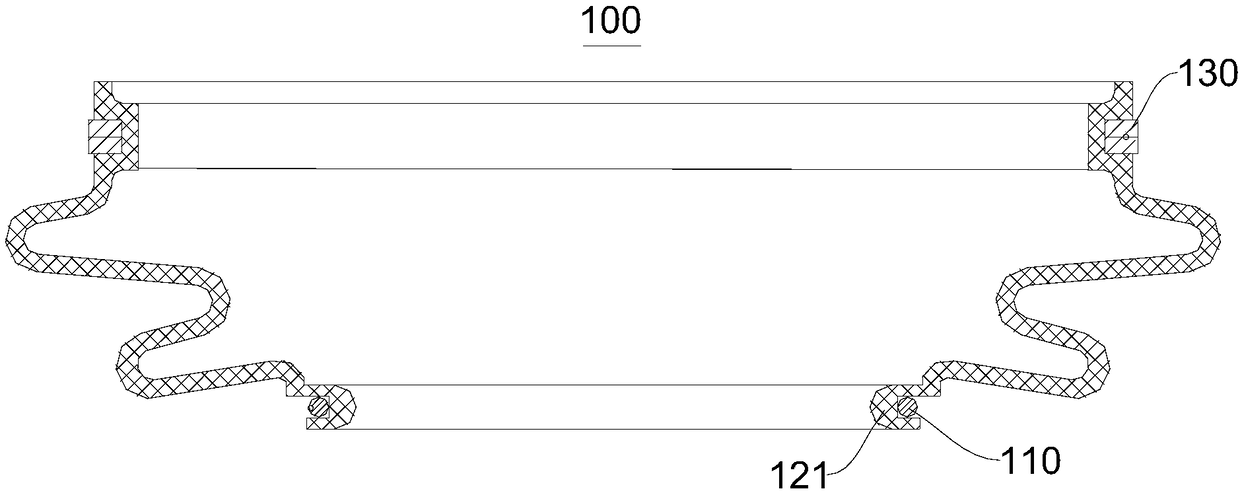

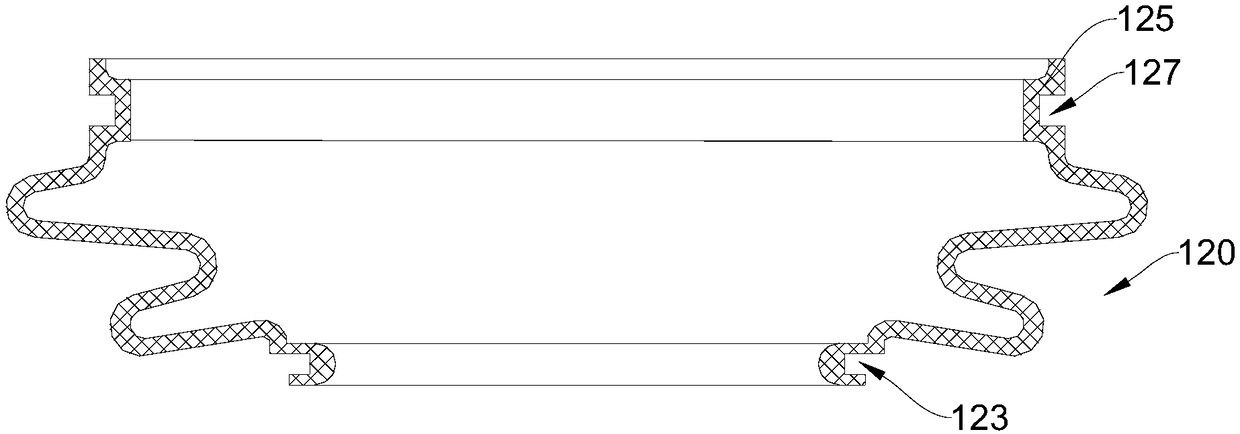

[0040] Please refer to figure 1 and figure 2 , this embodiment provides a bearing seal cover 100 , including a snap ring 110 , a seal cover 120 and a locking ring 130 . The snap ring 110 and the locking ring 130 are respectively detachably connected to two ends of the sealing cover 120 .

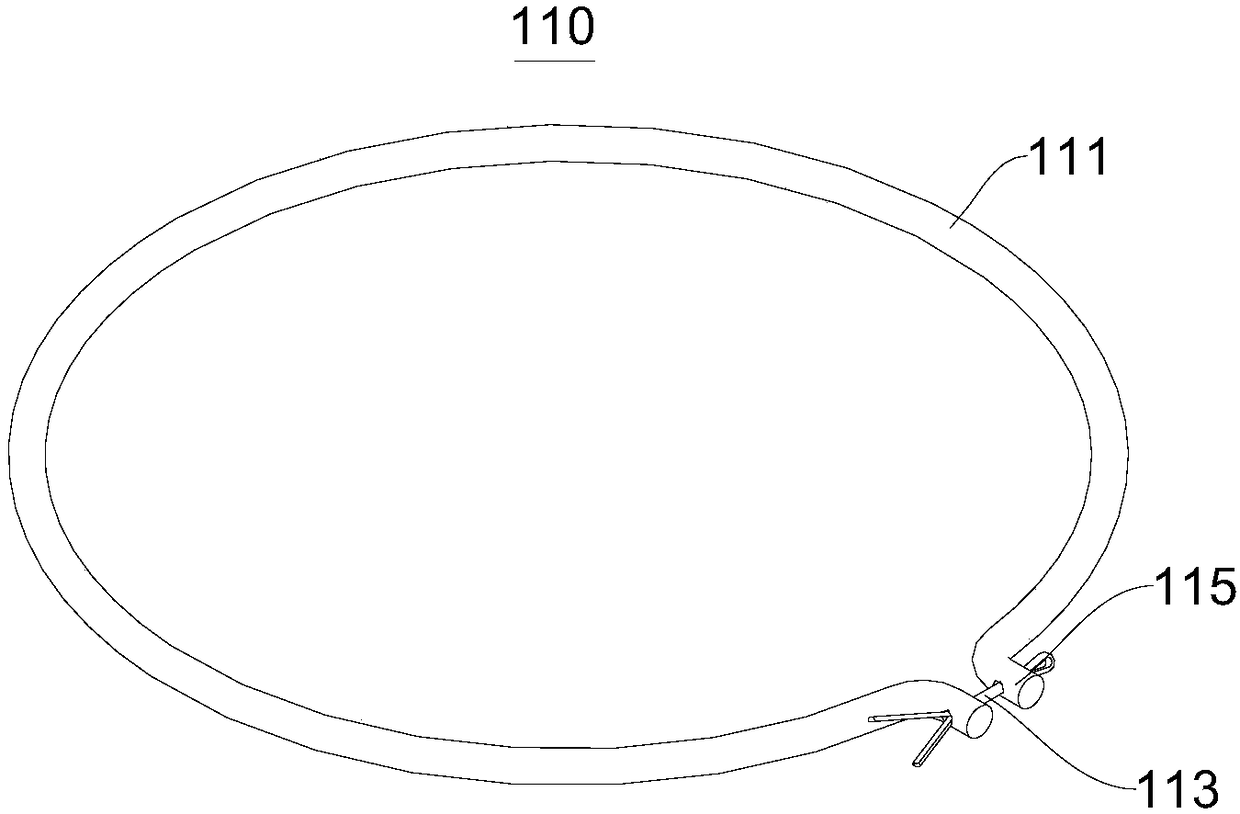

[0041] Please refer to image 3 and Figure 4 The snap ring 110 includes a first annular body 111 and a first connecting piece 113 , and the first and last ends of the first annular body 111 are detachably connected by the first connecting piece 113 . Specifically, both ends of the first annular body 111 have a first protruding portion 115 extending outward, and the first protruding portion 115 is provided with a first through hole 117, through which the first connecting member 113 passes through the first through hole 117 for The first and last ends of the first annular body 111 are connected. Compared with the existing single ring structure, this structure avoids the high swing frequ...

Embodiment 2

[0050] Please refer to Figure 7 , the present embodiment provides a bearing sealing structure 200 based on the bearing sealing cover 100 , including the connecting rod 210 , the ball bearing 220 and the bearing sealing cover 100 . The end of the connecting rod 210 is provided with a groove 211 matching with the ball bearing 220. The ball bearing 220 includes a ball head 221 and a ball seat 223. Most of the ball head 221 is arranged in the groove 211 and is arranged in the groove. The part outside 211 is connected with the ball seat 223 . Both ends of the sealing cover 120 are detachably connected to the connecting rod 210 and the ball bearing 220 respectively.

[0051] A first annular groove 225 matching the first engaging portion 121 is formed on the outer surface of the ball head 223 near the end of the ball head 221 , and the first engaging portion 121 is engaged in the first annular groove 225 . Then the sealing cover 120 is connected with the ball bearing 220 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com