Spin-drying device and application method

A drying barrel and installation space technology, which is applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problems of single driving mode, poor adaptability, and inability to meet the needs of use, so as to achieve good adaptability and set Reasonable and simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

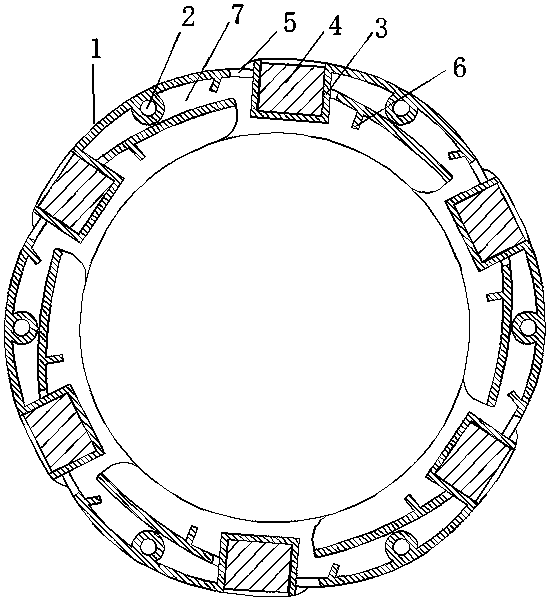

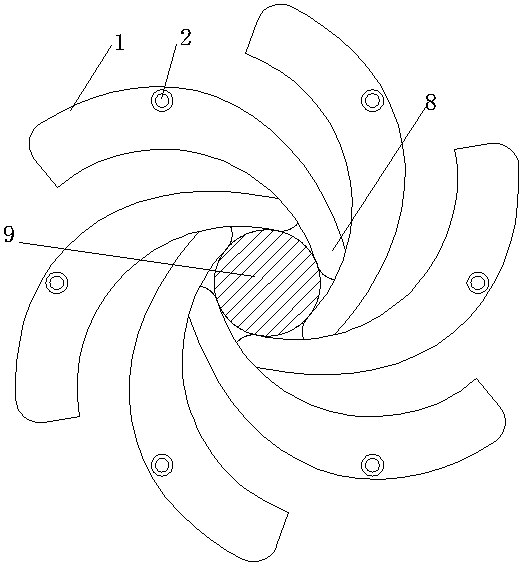

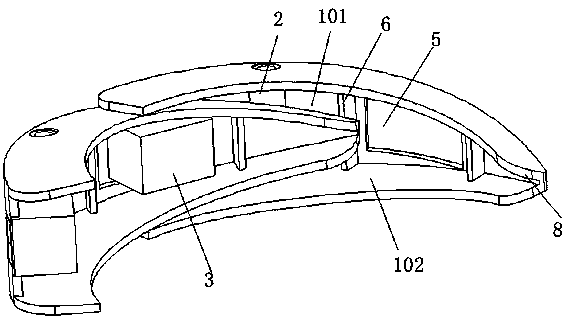

[0030] Such as Figure 1-9 As shown, a spin-drying device includes a housing 25, a base 26 disposed on the lower part of the housing 25, a power assembly disposed on the base 26, an upper cover 27 is hinged on the upper part of the housing 25, and an independent space is provided on the lower part of the housing 25. The installation space, the power assembly is located in the installation space, the shell 25 is provided with a spin-drying barrel 30, the upper and lower sides of the spin-drying barrel 30 are provided with grill holes, and the inner space of the shell at the bottom of the spin-drying barrel 30 forms a water collection tank 49, A water outlet is set on the sump 49, and the power assembly includes a pedal 29 stretched out of the housing from the installation space, a central shaft 34 vertically arranged in the installation space, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com