System and method for monitoring eccentricity of turbine-generator unit shaft system online

A turbogenerator set and monitoring system technology, applied in the direction of mechanical measuring devices, measuring devices, electrical devices, etc., can solve the problems of time limitation, rewiring and installation of equipment, failure to realize shaft eccentricity and phase, etc., to avoid time The effect of restriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention is further introduced:

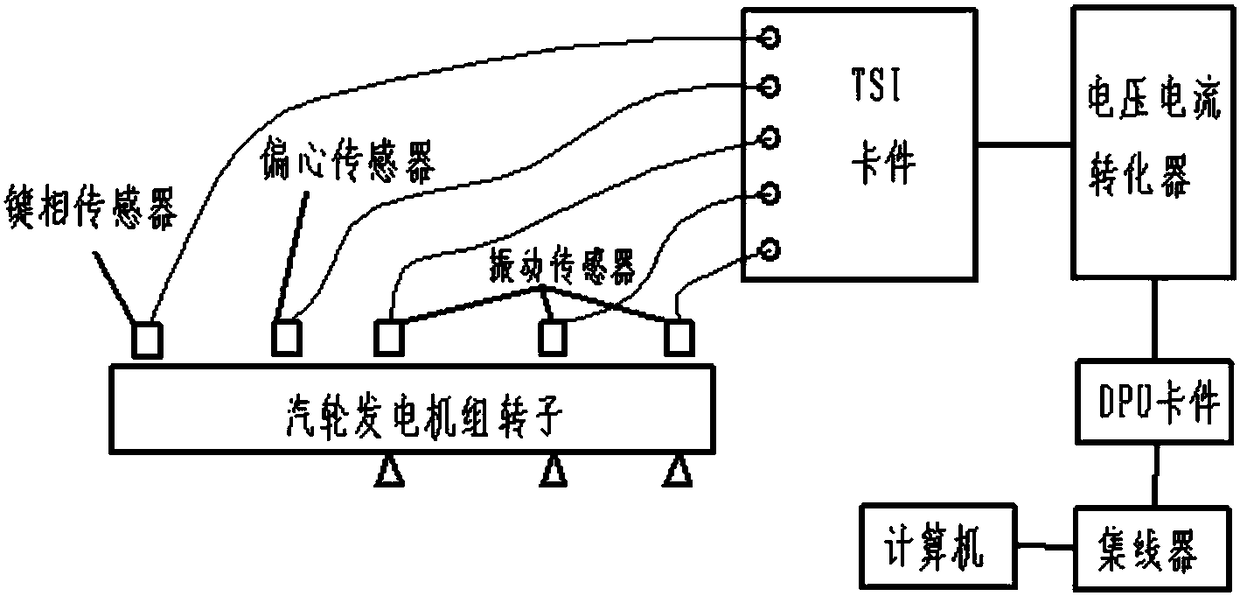

[0034] refer to figure 1

[0035] An on-line monitoring system for shafting eccentricity of a steam turbine generator set, including a TSI clip and a turbine engine set rotor, and a key phase sensor installed on the turbine engine set rotor or at the position where there is a measuring groove on the circumferential surface of the turbine engine set rotor extension shaft , and the key phase sensor is on the surface of the rotor where the measuring groove is located; the eccentric sensor is installed close to the front end of the rotor of the steam turbine engine set, and is perpendicular to the surface of the rotor of the steam turbine engine set; the vibration sensor is installed at each bearing bush of the rotor of the steam turbine engine set, It is perpendicular to the rotor surface of the steam turbine engine set; the key phase sensor, eccentric sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com