A calibration device for online metering and calibration of oil-gas-water multiphase flow

A technique for calibrating, multiphase flow, used in test/calibration devices, measuring devices, test/calibration volume flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

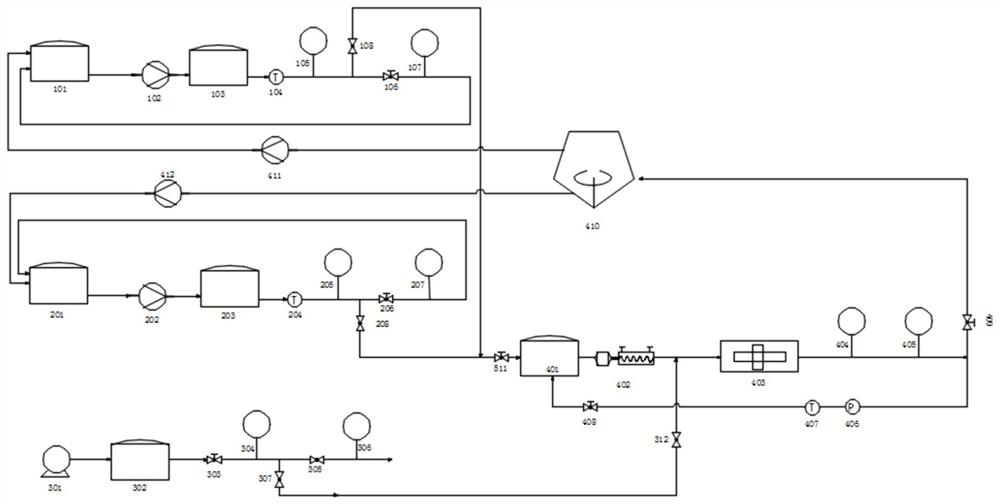

[0019] like figure 1As shown, an oil-gas-water multiphase flow on-line measurement calibration and calibration device includes a single-phase oil calibration and calibration system 1, a single-phase water flow calibration and calibration system 2, a single-phase gas flow calibration and calibration system 3, a heating buffer tank 401, and a screw pump. 402, static mixer 403, standard meter 404, meter to be tested 405, pressure sensor 406, first temperature sensor 407, first regulating valve 408, first ball valve 409, separator 410, first quantitative plunger pump 411, The second quantitative plunger pump 412, the single-phase oil calibration and calibration system is connected to the first quantitative plunger pump 411 and the heating buffer tank 401 respectively through pipelines, and the single-phase water flow calibration and calibration system is connected through pipelines The pipelines are respectively connected with the second quantitative plunger pump 412 and the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com