Measuring method used for reciprocating movement

A technology of reciprocating motion and measuring method, applied in general control systems, instruments, digital control and other directions, can solve the problems of easy pollution and damage of the magnetic scale measuring device, and achieve the effect of avoiding frequent machine shutdowns and simple and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

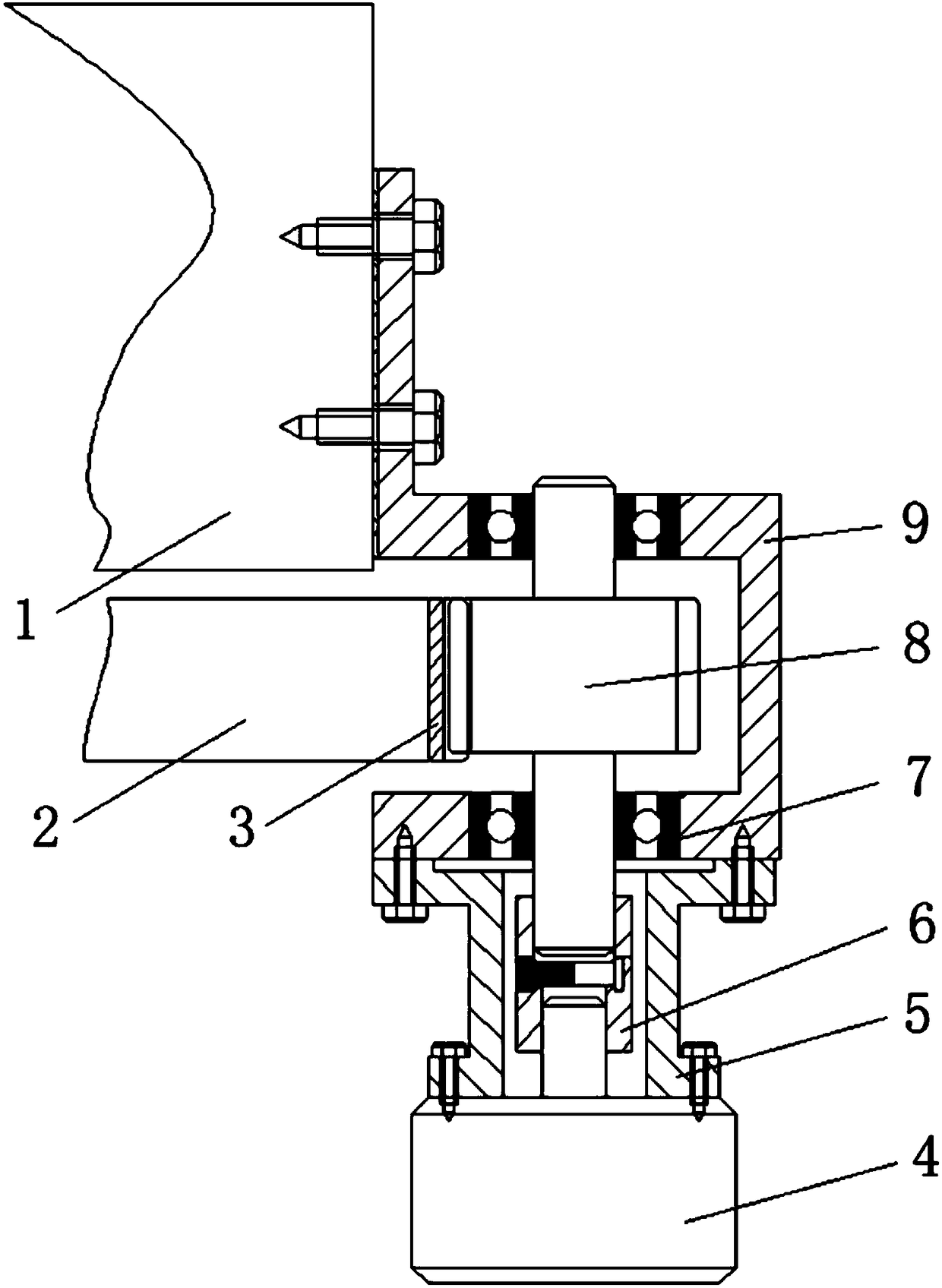

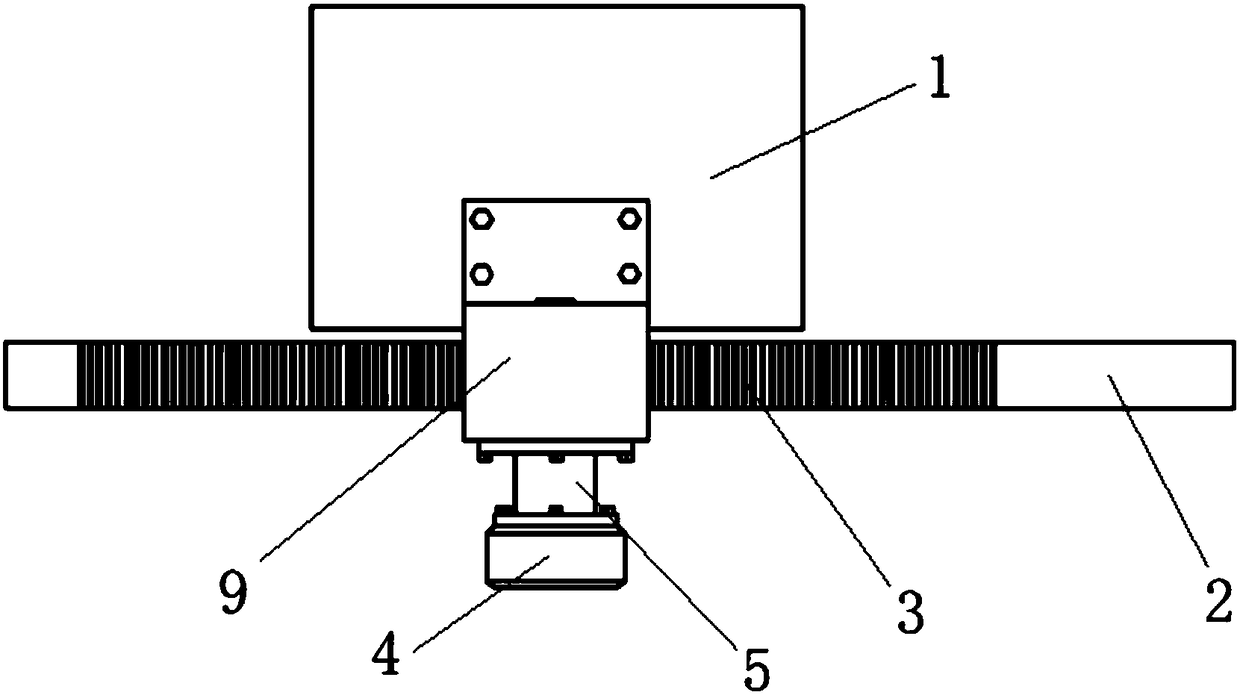

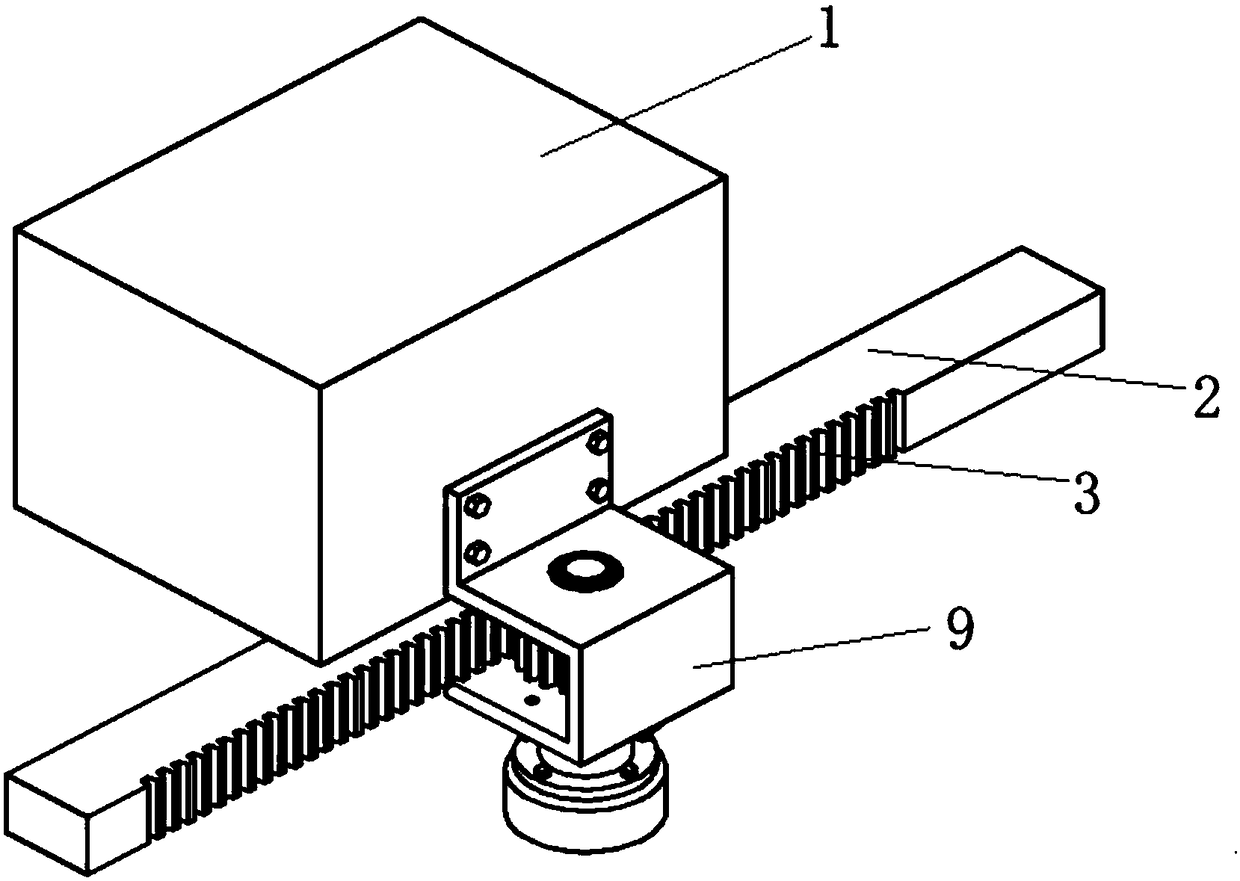

[0013] Referring to the accompanying drawings, in the reciprocating motion measuring method of the present application, a synchronous toothed belt 3 is fixed with a rivet on the machine body 2, and the length of the toothed belt is greater than the movement stroke of the workbench 1, and is parallel to the movement of the workbench 1 Direction; another detection device, the detection device contains an incremental encoder 4, a synchronous gear 8 and a connector 6, the central axis of the synchronous gear 8 passes through the coupling in the connector 6 and the incremental encoder 4 The main shaft is connected, the central axis of the synchronous gear 8 is fixed on the gear box 9 through the bearing seat 7, the extension arm of the gear box 9 is fixed on the reciprocating worktable 1, the synchronous gear 8 and the synchronous toothed belt 3 toothed Engagement, movement is synchronized and smooth.

[0014] When the worktable 1 reciprocates, the synchronous gear 8 rotates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com