Macroscopic-microscopic collaborative optimization method of structure of material containing elliptical holes

A collaborative optimization, elliptical technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as single microscopic holes, and achieve the effect of realizing design and improving stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

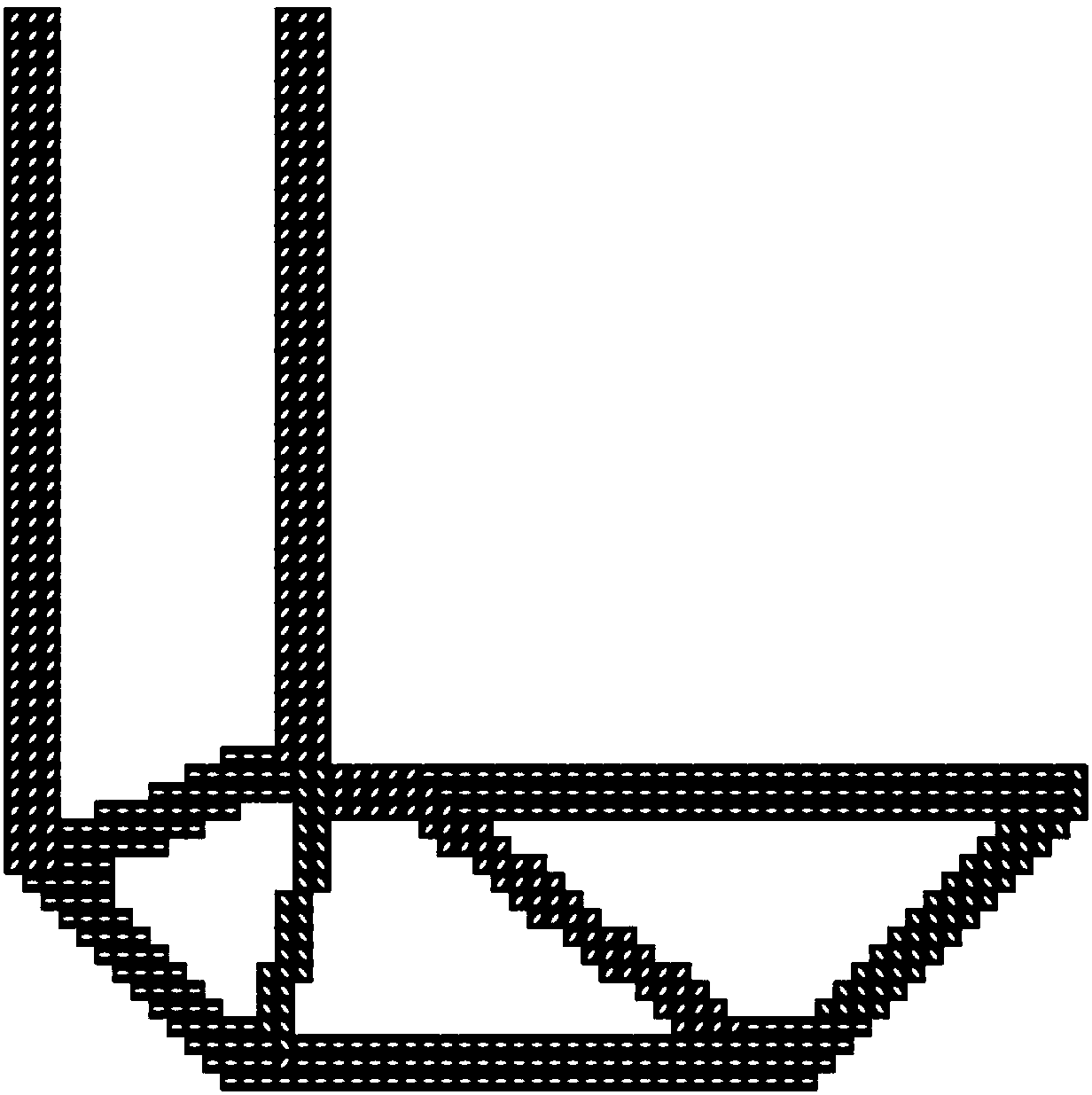

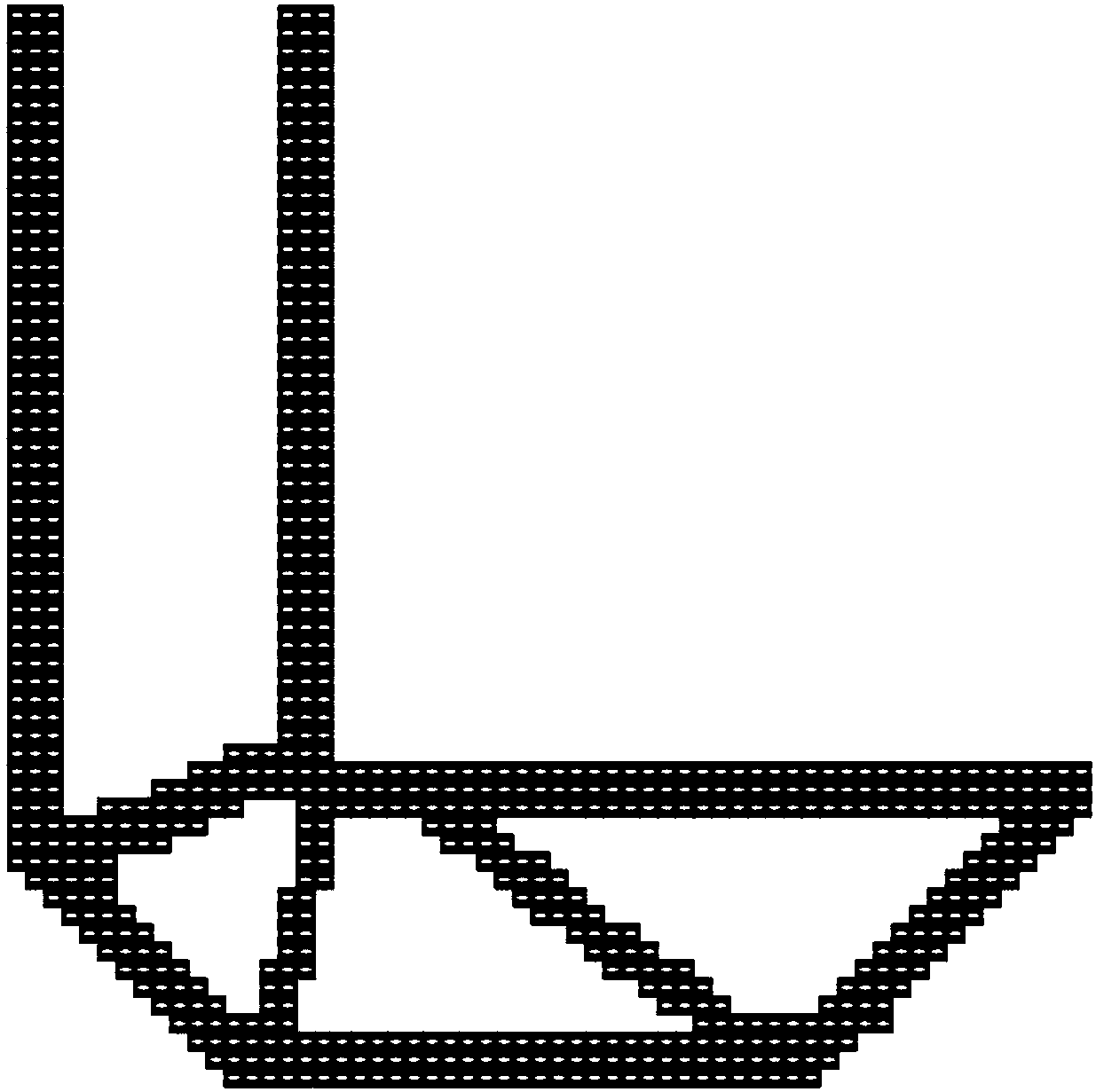

[0034] refer to Figure 1~4 , taking the L-shaped beam structure as the object of topology optimization, considering the elliptical hole angle of the porous material and the collaborative design of the structure as an example to illustrate the present invention. The method steps are as follows:

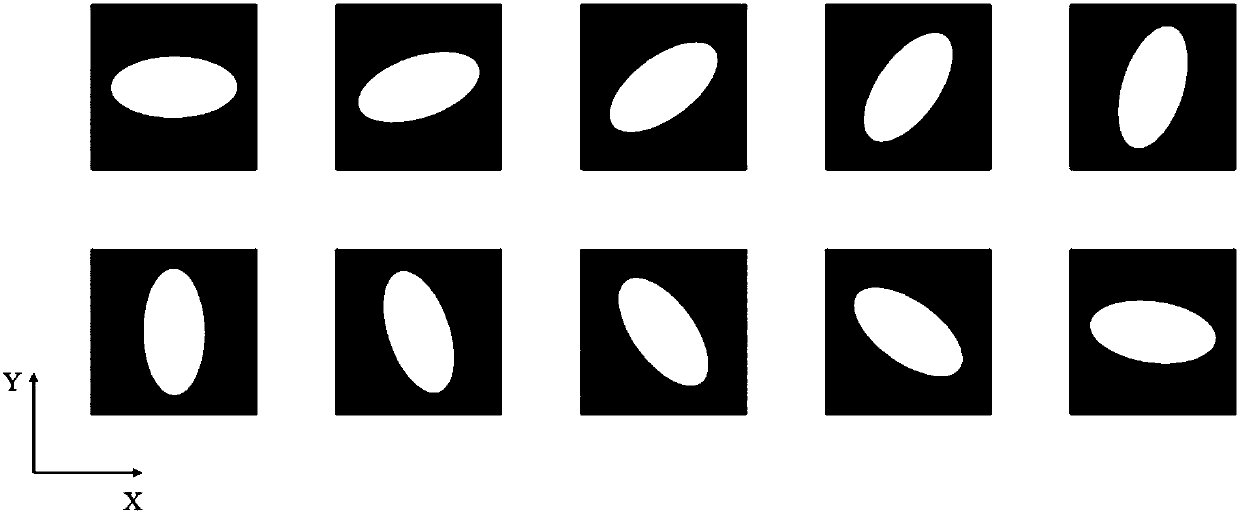

[0035] Step 1: Use a porous material unit cell with an elliptical hole, the side length of the unit cell is 1 mm, the major axis of the elliptical hole is 0.4 mm, and the minor axis is 0.2 mm. Use the homogenization method to predict the equivalent performance of the material, and establish the functional relationship between the angle parameter of the elliptical hole in the material unit cell and the equivalent performance: D H (θ)=f(θ)·D H , f(θ) is a polynomial interpolation function about the ellipse angle parameter of the porous material;

[0036] Step 2: Use th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com