Device and method for collaborative slab design of steel products with complex slab shape in multi-production lines of iron and steel enterprises

A technology of slab and slab shape, which is applied in the field of collaborative slab design device for complex slab shape of steel products produced by multiple production lines of iron and steel enterprises, which can solve the problems that the design efficiency cannot meet business needs, manual on-site design, low degree of automation and intelligence, etc. , to achieve the effect of realizing automation and intelligence, reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

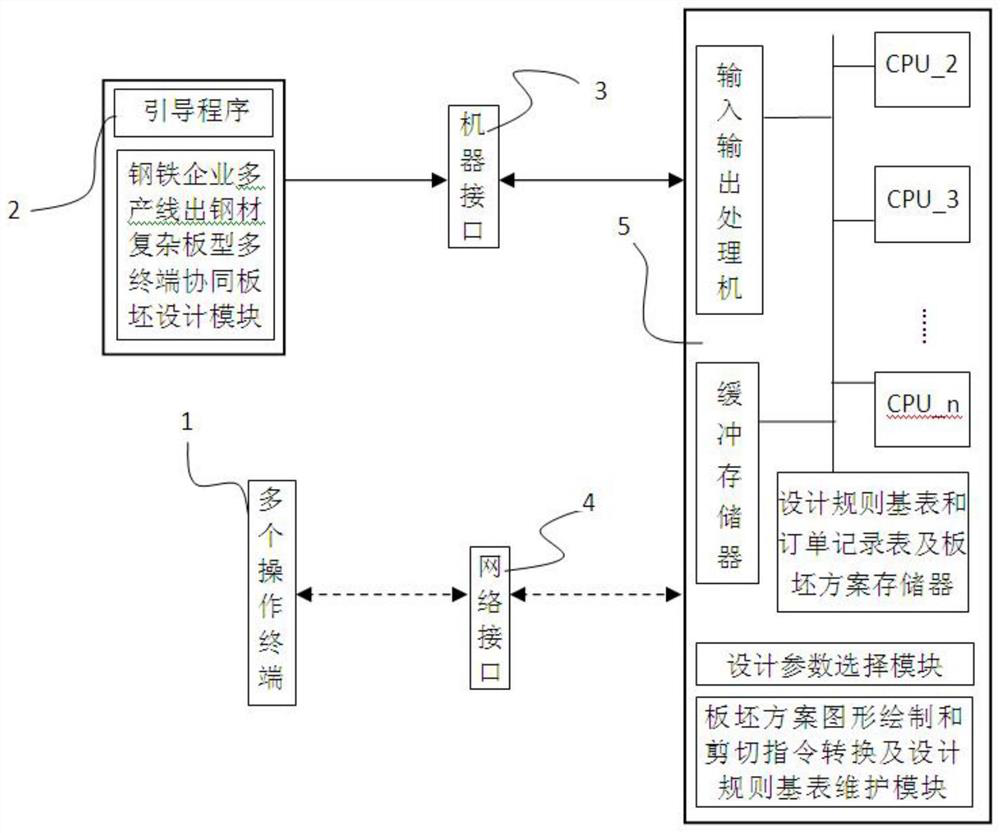

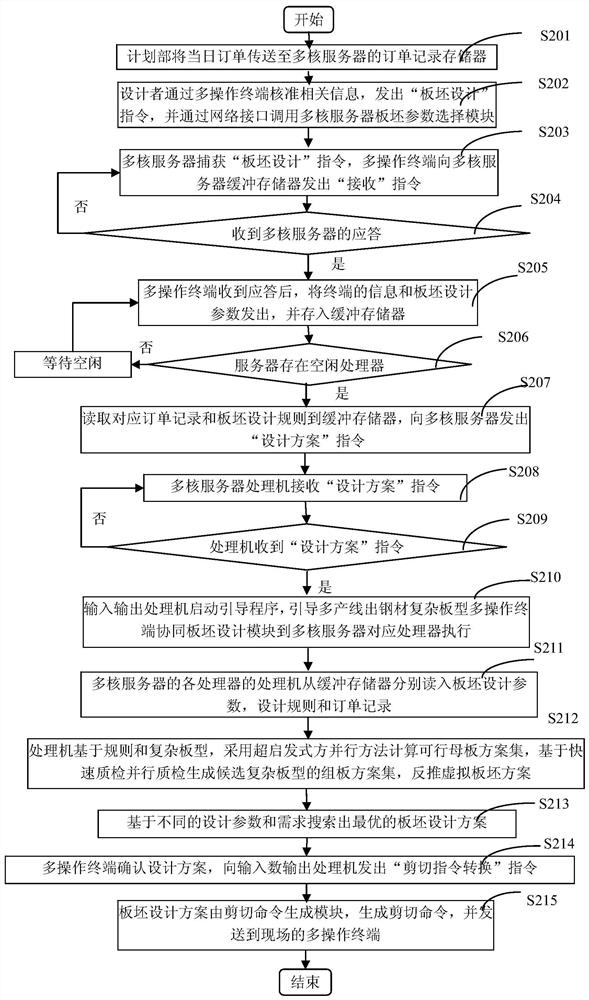

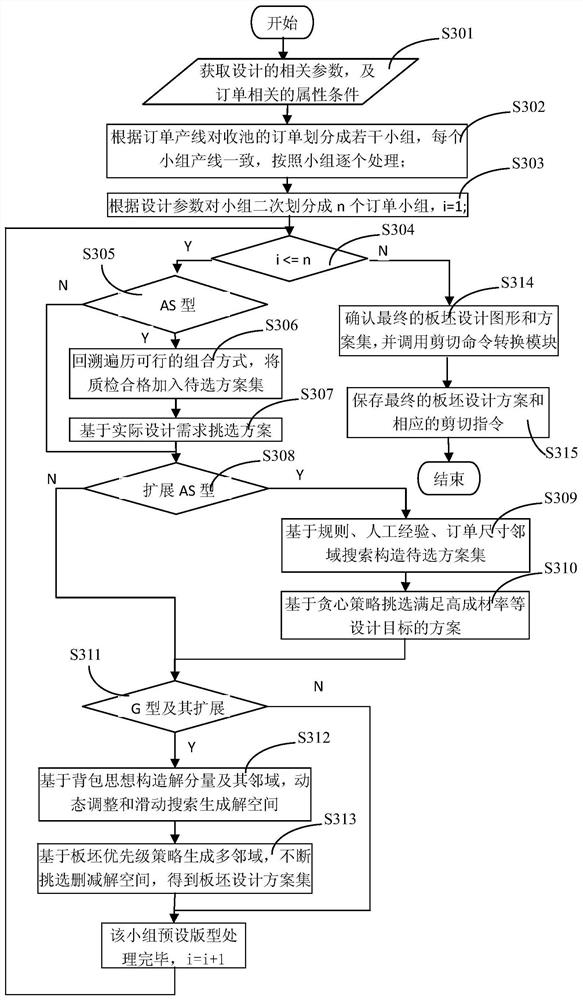

[0046] see figure 1 , the iron and steel enterprise multi-production line output steel complex slab collaborative slab design device of the present embodiment, it includes a plurality of operation terminals 1, a steel slab design unit 2, a multi-core server 5; a plurality of operation terminals 1 through the network interface 4 Connected with the multi-core server 5, the steel slab design unit 2 is connected with the multi-core server 5 through the machine interface 3; Billet scheme storage, slab scheme graphic drawing and cutting instruction conversion and design rule base table maintenance module, buffer memory and design parameter selection module, the steel slab design unit 2 includes the complex steel plate shape of the multi-production line of the iron and steel enterprise Multi-terminal collaborative slab design module and bootstrap; w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com