Backside illuminated image sensor and manufacturing method thereof

An image sensor, back-illuminated technology, applied in electric solid devices, semiconductor devices, radiation control devices, etc., can solve the problems of affecting the photoelectric sensitivity of BSI image sensors, affecting the photoelectric sensitivity of photoelectric sensing devices, etc., to improve the photoelectric sensitivity, The effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

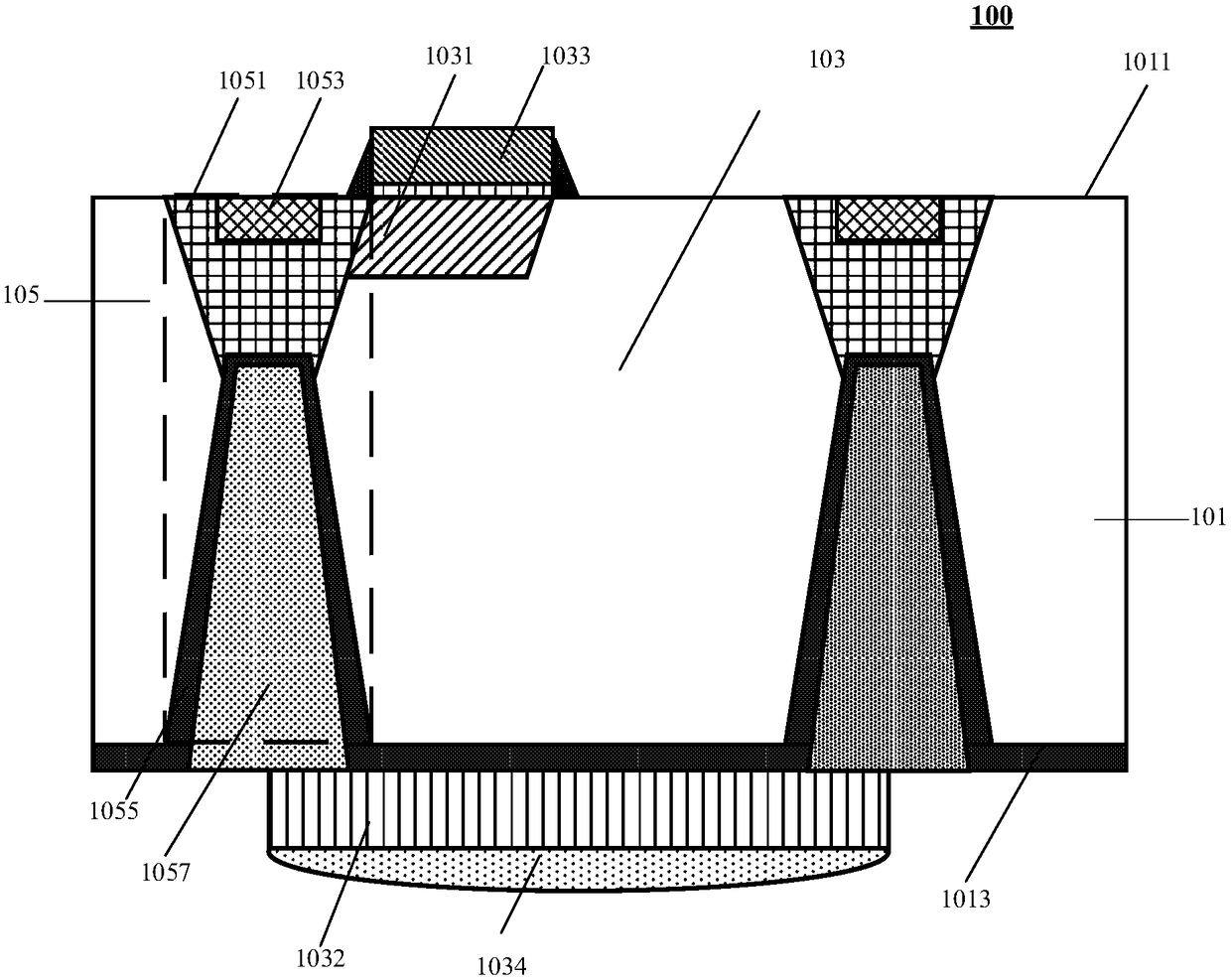

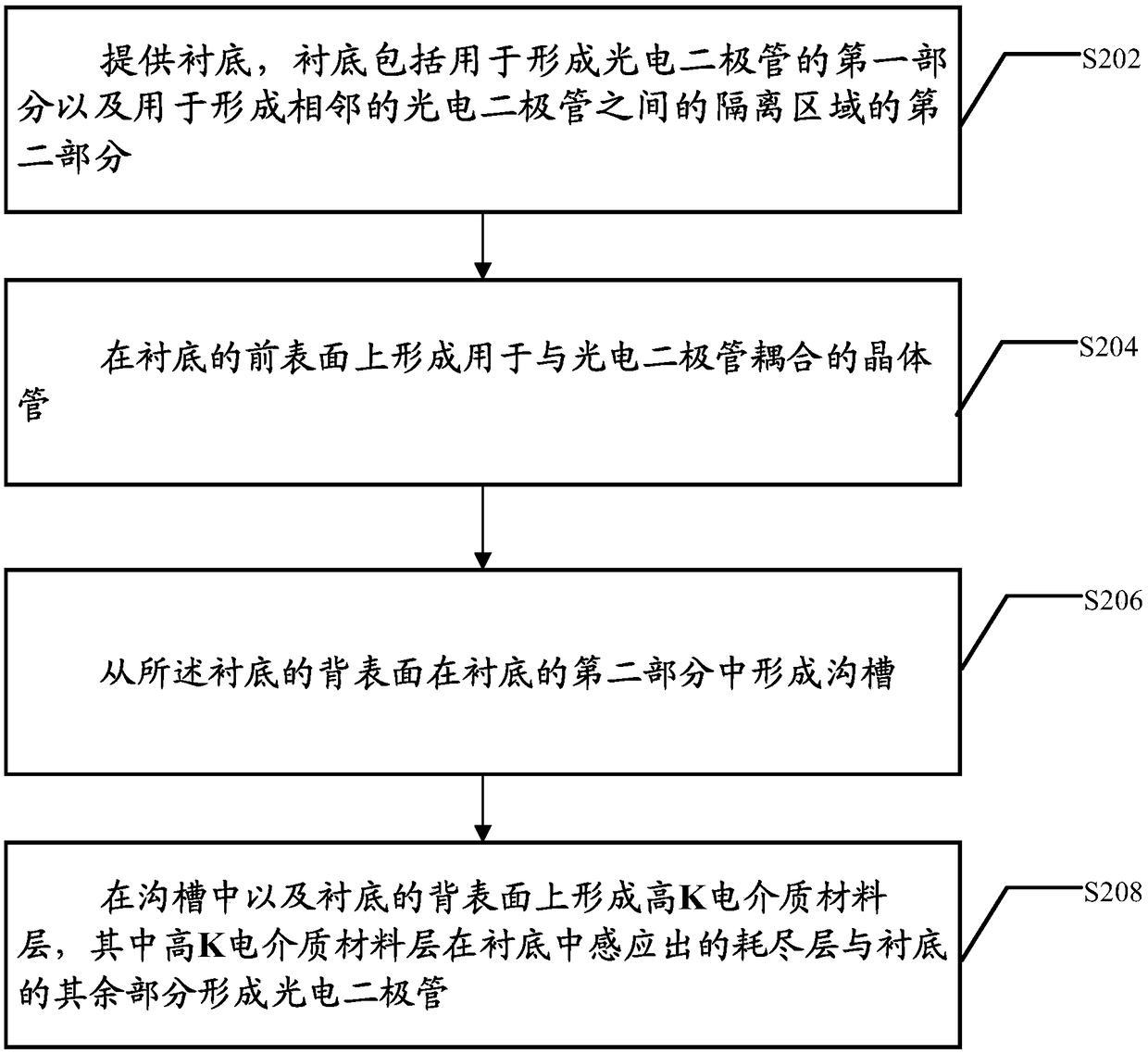

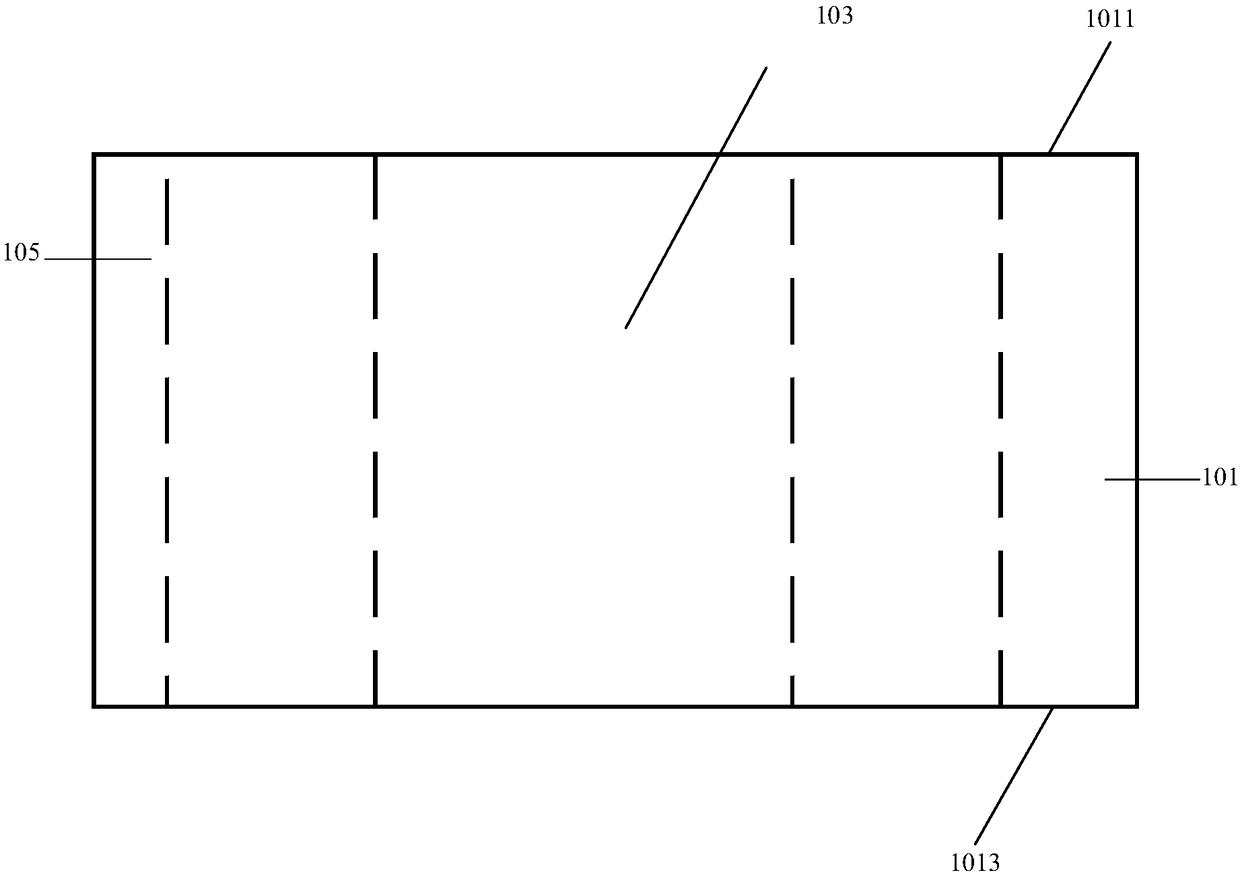

[0018] Embodiments disclosed in this specification will be described in detail below with reference to the drawings. However, it should be understood that the descriptions of various embodiments are only illustrative, and are not intended to limit the invention claimed in this application in any way. Unless otherwise specifically stated or the context or its principle is explicit or implied, the relative arrangement, expression and numerical value, etc. of components and steps in the exemplary embodiment are not intended to limit the invention to be protected in the present application. In this specification, techniques, methods and devices known to persons of ordinary skill in the related art may not be discussed in detail, but under appropriate circumstances, the techniques, methods and devices should be considered as part of the specification.

[0019] The terms used herein are for describing specific embodiments only, and are not intended to limit the present disclosure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com