Reversible rotary compressor

A two-way rotation, compressor technology, applied in compressors, irreversible cycle compression machines, rotary piston machines, etc., can solve problems such as low reliability of compressors and increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

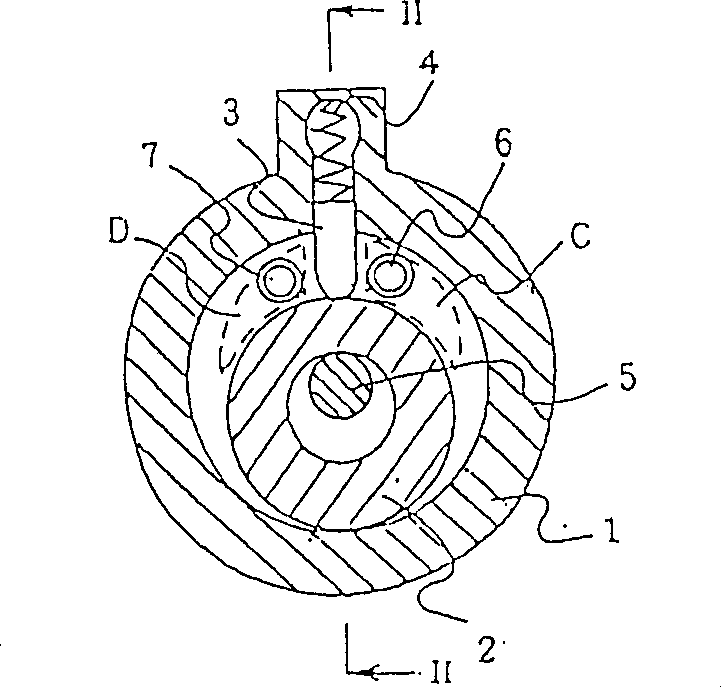

[0034] figure 1 A cross-sectional view shows a reversible rotary compressor according to a first embodiment of the present invention. The number 1 in the figure represents a cylinder; 2 is a rolling piston; 3 is a sliding plate; 4 is a spring for making the sliding plate 3 close to the rolling piston 2; 5 is the crankshaft of the rolling piston 2; C and D For the inlet / outlet, they are arranged in the space between the inner surface of the cylinder 1 and the outer surface of the rolling piston 2, and are symmetrically arranged on both sides of the sliding plate 3; The refrigerant is supplied to the inlet / outlet C or discharged from the inlet / outlet C; the inlet 7 is used as a refrigerant pipe for supplying the refrigerant to the inlet / outlet D or discharging the refrigerant from the inlet / outlet D. The refrigerant pipes 6 and 7 are closed by the rolling piston 2 when the rolling piston 2 reaches the top dead center, and are opened when it is at the bottom dead center.

[00...

Embodiment 2

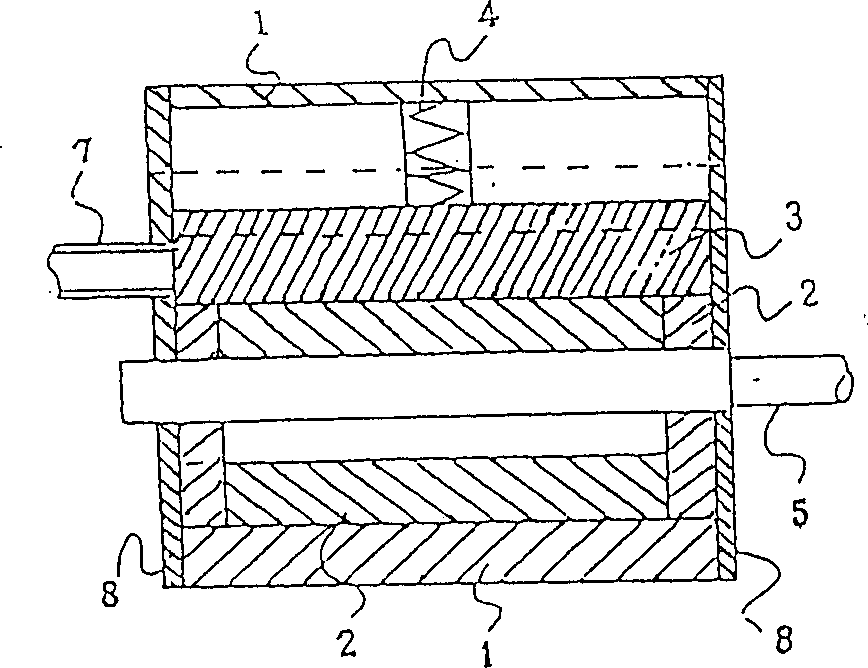

[0047] As previously described, in Embodiment 1, the refrigerant pipes 6 and 7 connected to the inlet / outlet ports C and D are arranged on only one side wall 8 of the cylinder 1 . These refrigerant pipes can also be arranged as required, that is, the refrigerant pipe 6 connected to the inlet / outlet C is arranged on the side wall 8 of the cylinder 1, and the refrigerant pipe connected to the inlet / outlet D 7 is set on the other side wall 8 ( Figure 7 ).

[0048] In the refrigerant tubes thus arranged, the flow of refrigerant is unidirectional and thus smooth.

Embodiment 3

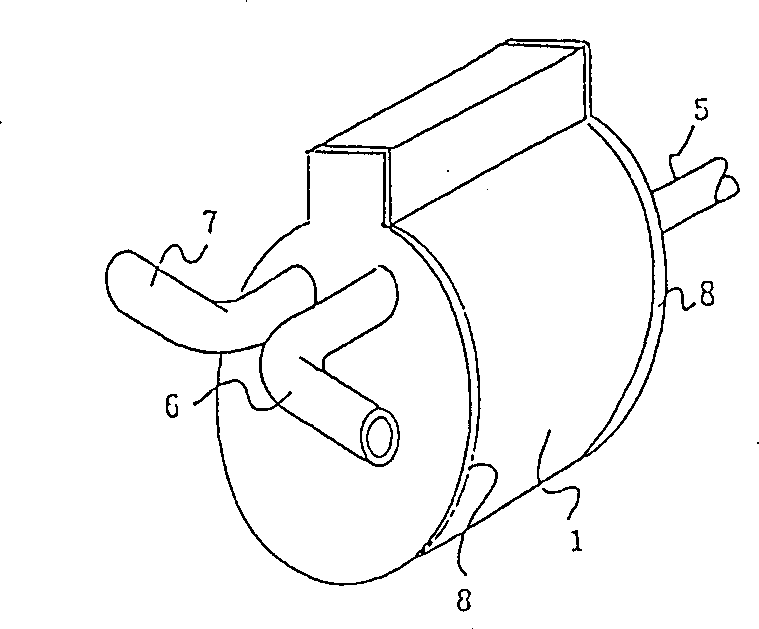

[0050] Figure 8 The perspective view of is showing the appearance of the reversible rotary compressor according to the third embodiment of the present invention. The refrigerant pipes 6 and 7 connected to the inlet / outlet ports C and D in this example are each connected to both walls of the cylinder 1 as shown in the figure.

[0051] This connection of the refrigerant tubes uniformly supplies the refrigerant to the cylinder 1, resulting in smooth compression of the refrigerant. In addition, the suction area is doubled to reduce the suction loss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com