Laminate, method for producing laminate, and personal authentication medium

A manufacturing method and a technology for a laminated body, which are applied in chemical instruments and methods, lamination, and layered products, etc., can solve problems such as easy breakage, damage to the transfer layer, and increased risk of deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

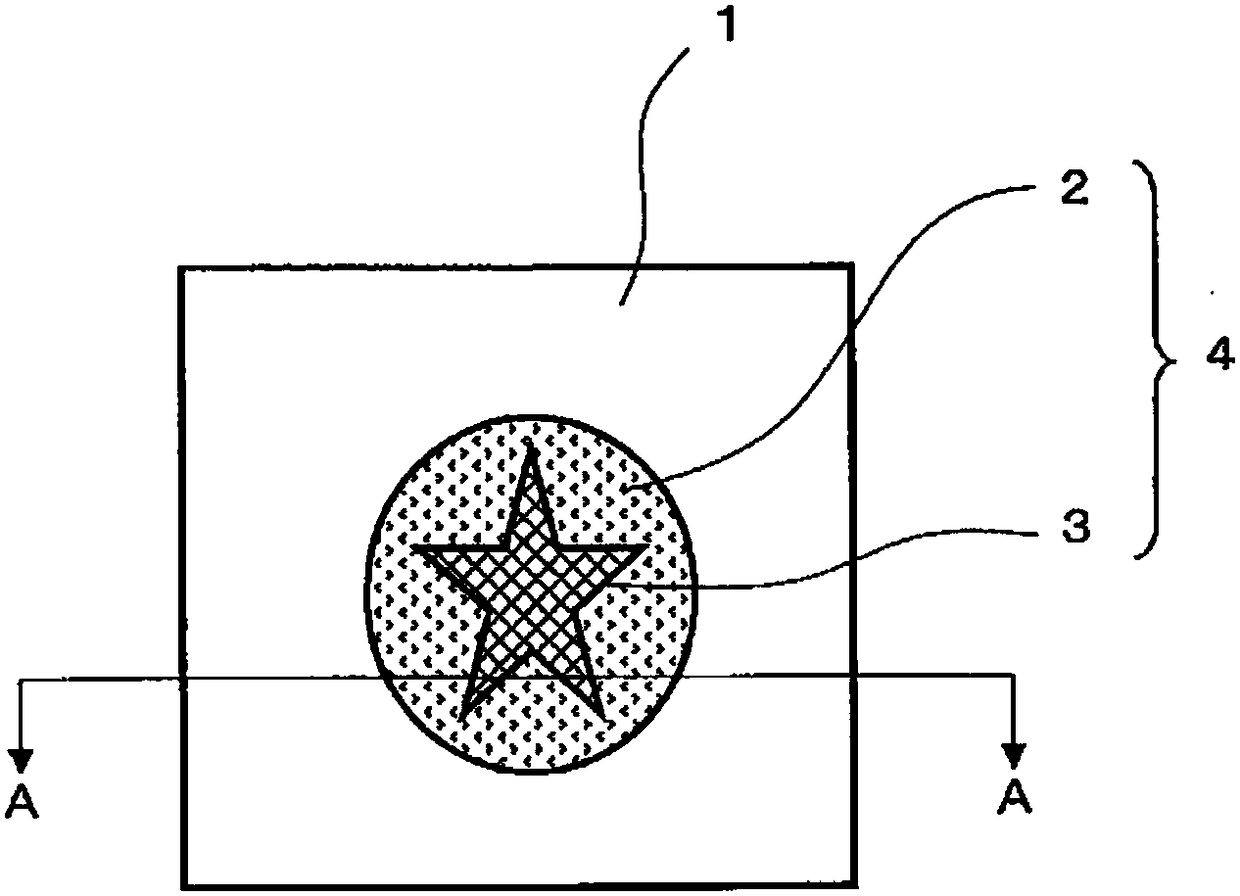

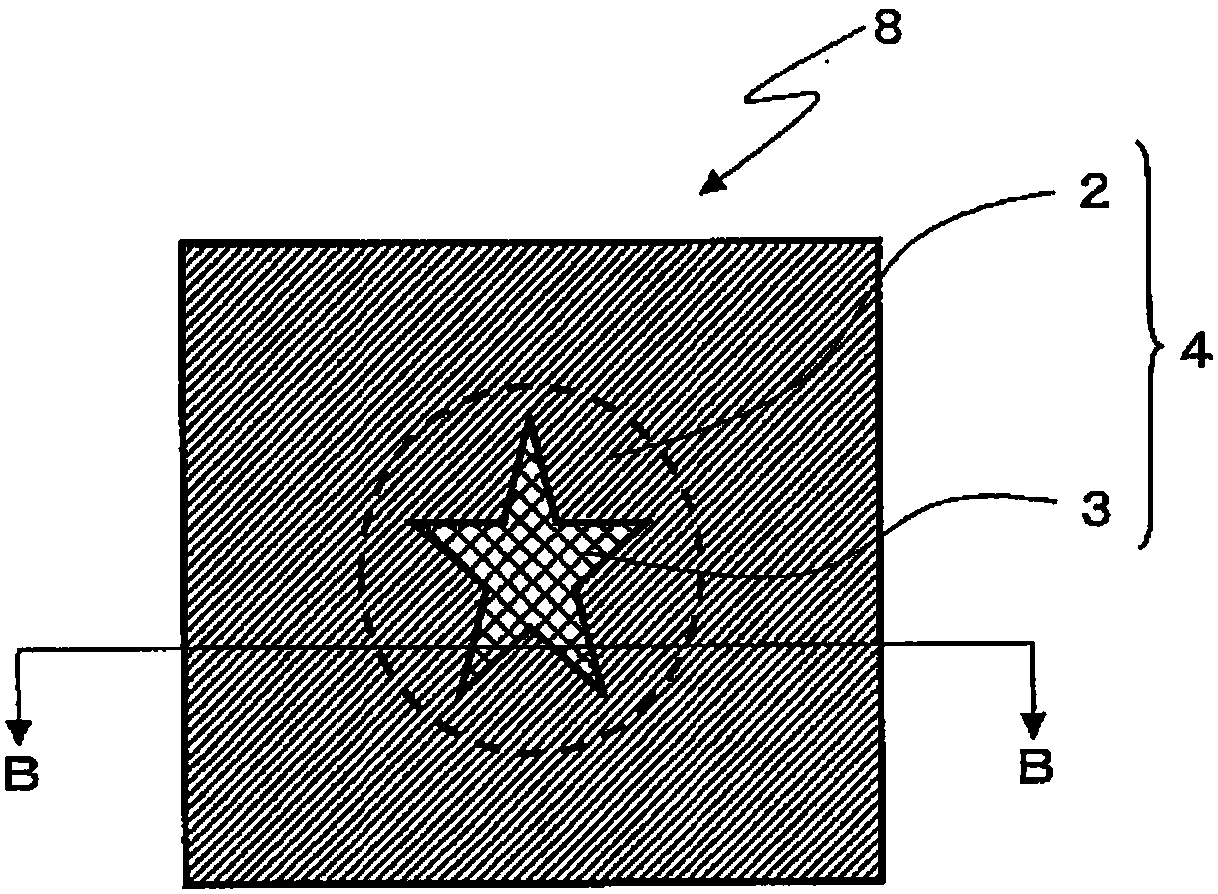

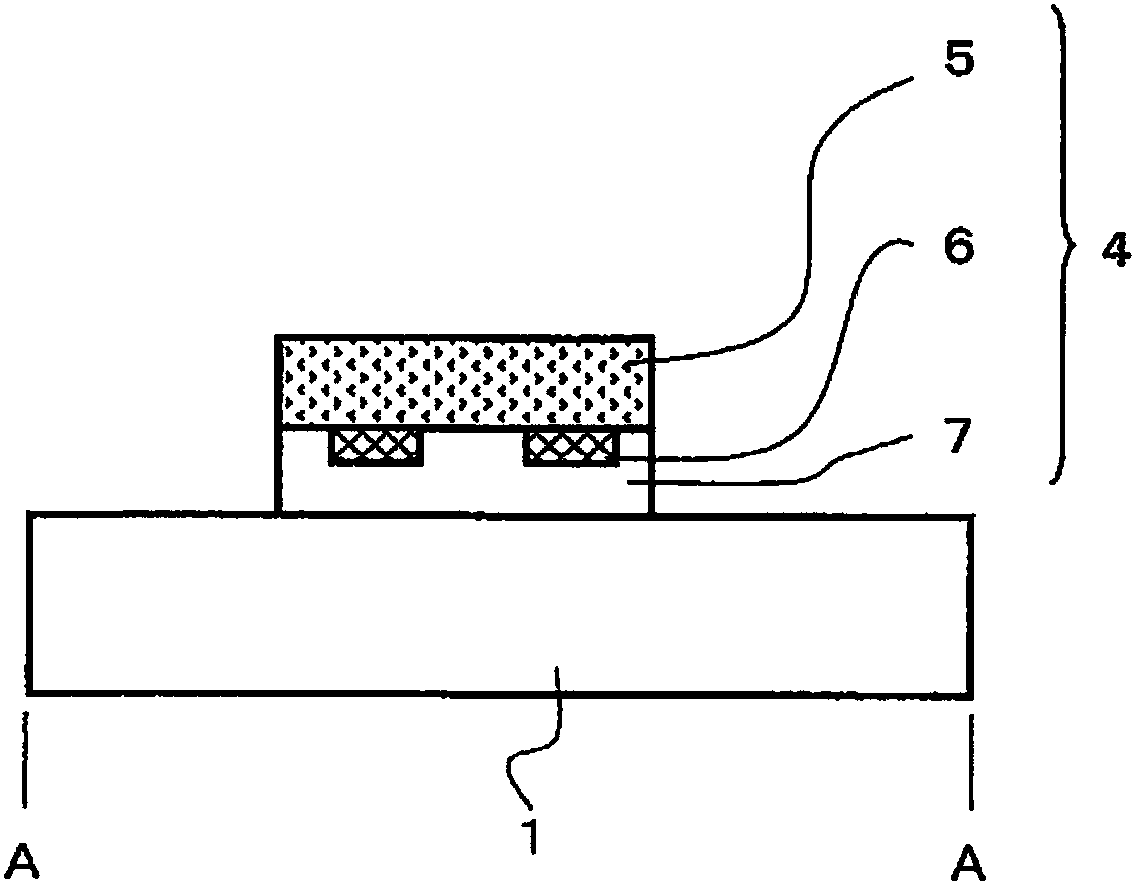

[0064] Figure 1A It is a top view schematically showing the structure of the polycarbonate laminate according to the first embodiment before lamination and integration, Figure 1B It is a plan view schematically showing the configuration of the polycarbonate laminate according to the first embodiment in a state where the laminates are integrated. in addition, Figure 2A yes means Figure 1A The cutaway view of section A-A of Figure 2B yes means Figure 1B The sectional view of the BB section.

[0065] Figure 1A A state in which the transfer layer 4 is attached to the first polycarbonate layer 1 is shown. In a plan view opposite to the plane on which the transfer layer 4 extends, the transfer layer 4 consists of a region where the transparent reflective layer is not located, i.e. the first region 2, and a star-shaped region where the transparent reflective layer is located, i.e. the second region 3 constitute. In addition, it can be observed that the transfer layer 4 is...

no. 2 Embodiment approach

[0103] Figure 3A to Figure 3C It is a plan view schematically showing the configuration of the polycarbonate laminate according to the second embodiment in a state where the laminates are integrated. exist Figure 3A to Figure 3C Each of these shows a first cross-sectional region 9 having a first cross-section, a second cross-sectional region 10 having a second cross-section, and a third cross-sectional region 11 having a third cross-section.

[0104] exist Figure 3A In the illustrated polycarbonate laminate 8 , the third cross-sectional region 11 having the third cross-section has a star shape in plan view opposed to the plane in which the polycarbonate laminate 8 extends. exist Figure 3B In the illustrated polycarbonate laminate 8 , the third cross-sectional region 11 has a shape of "A", which is one of capital letters, in a plan view opposed to the plane in which the polycarbonate laminate 8 extends. exist Figure 3C In the illustrated polycarbonate laminate 8 , in ...

no. 3 Embodiment approach

[0108] Figure 4 It is a top view schematically showing the structure of the polycarbonate laminate according to the third embodiment in a state where the laminates are integrated. exist Figure 4 In the polycarbonate laminated body 16 shown in , a first cross-sectional region 9 having a first cross-section, a second cross-sectional region 10 having a second cross-section, and a third cross-sectional region 11 having a third cross-section are shown. Furthermore, the third cross-sectional area 11 having the third cross-section is constituted by a plurality of third cross-sectional elements.

[0109] Among the plurality of third cross-sectional elements, the first element 11A has a rod shape, two first elements 11A are arranged at a small interval, the second element 11B has a curved figure, the third element 11C has a dotted line shape, and the fourth element 11D has a point linear.

[0110] More specifically, the first element 11A has a rod shape extending along an elongati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com