Method for compacting the ballast bed of a track, and tamping unit

A ballast and track technology, applied in the field of tamping units for ballast compaction, can solve the problem that the ballast compaction degree cannot be obtained, and achieve the effects of uniform sleeper track bed, uniform compaction quality, and reduced wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

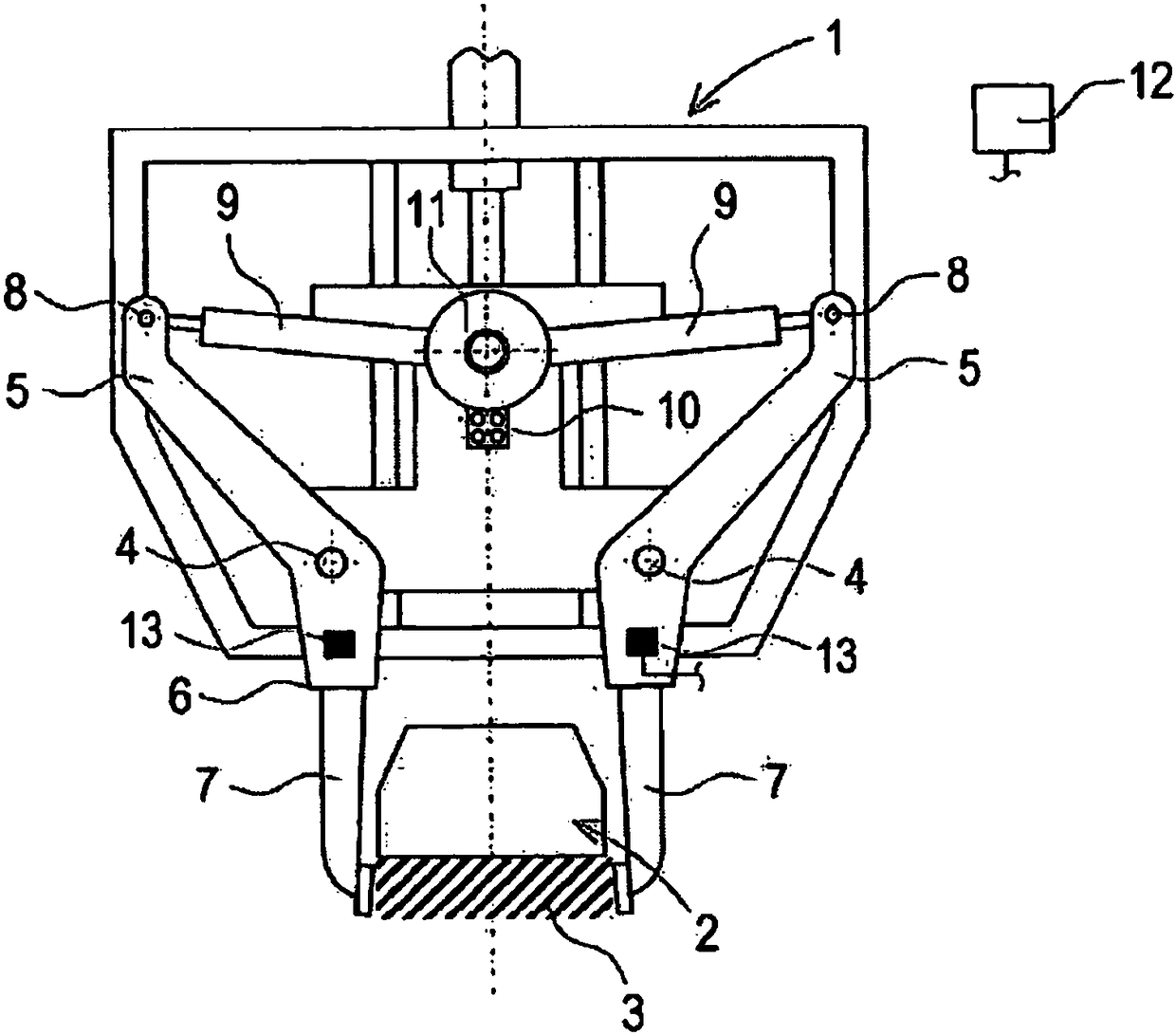

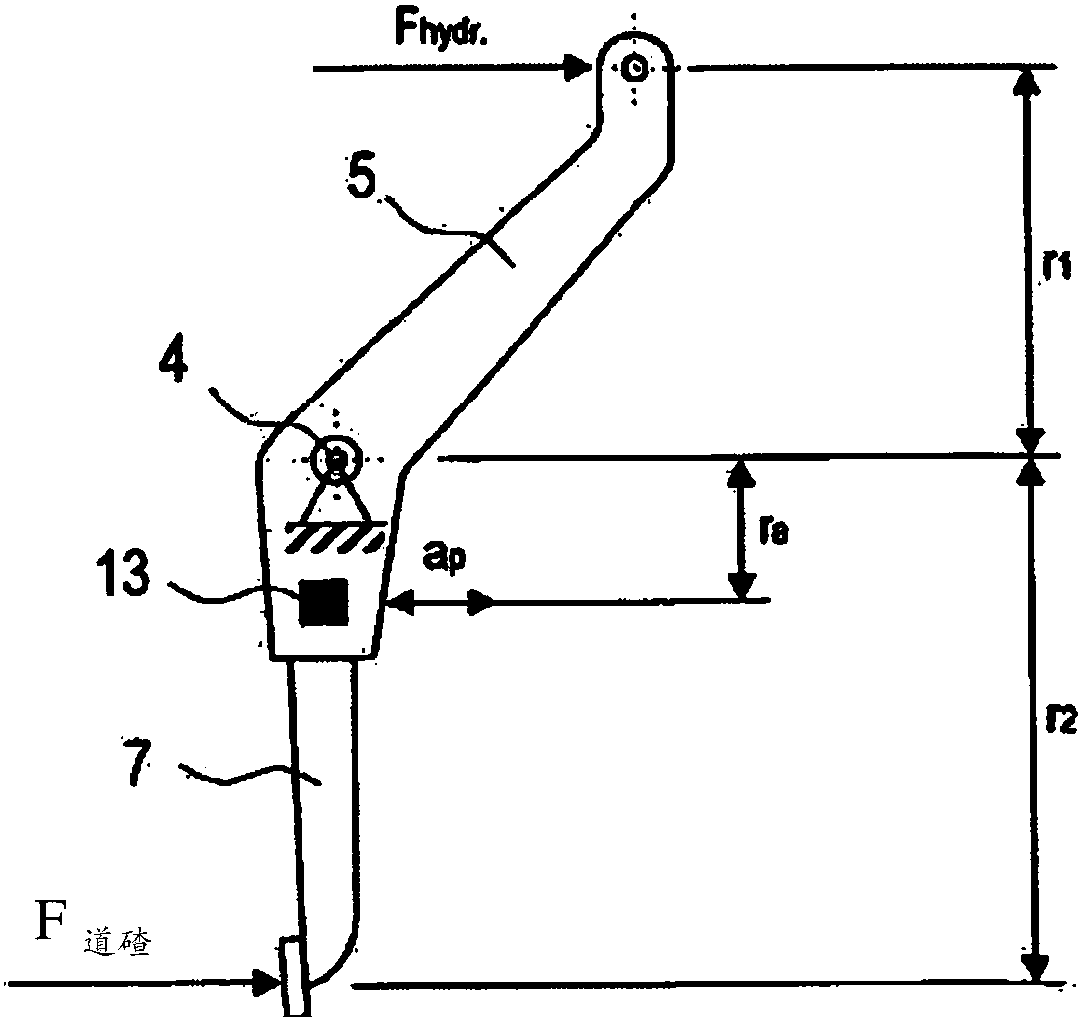

[0017] exist figure 1 The tamping unit 1 shown in a simplified manner is used for tamping the ballast 3 of the ballast bed below the track 2, and the tamping unit basically consists of two tamping rods 5, each of which can be Pivot about pivot axis 4 . At the lower end 6, these tamping rods 5 are respectively connected with a compacting tool or a tamping pick 7, which is provided for penetrating into the ballast 3, and the tamping rods 5 are connected at the upper end 8 is connected to the hydraulic squeeze driver 9.

[0018] Each extrusion drive 9 is mounted on an eccentric shaft 11 which can be rotated by the eccentric drive 10 . As a result, oscillatory oscillations are generated, which are transmitted to the ballast 3 to be compacted via the squeeze drive 9, the tamping rod 5 and the compacting tool 7. At the lower end 6 of each tamping rod 5 there is arranged an acceleration sensor 13 which is connected to the control unit 12 . Alternatively, however, the acceleration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com