Removable electrical connectors for flattened lighting modules

A lighting module and electrical connection technology, applied in the field of lighting, can solve the problem of not being thin, and achieve the effect of being easy to manufacture and reducing manufacturing tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

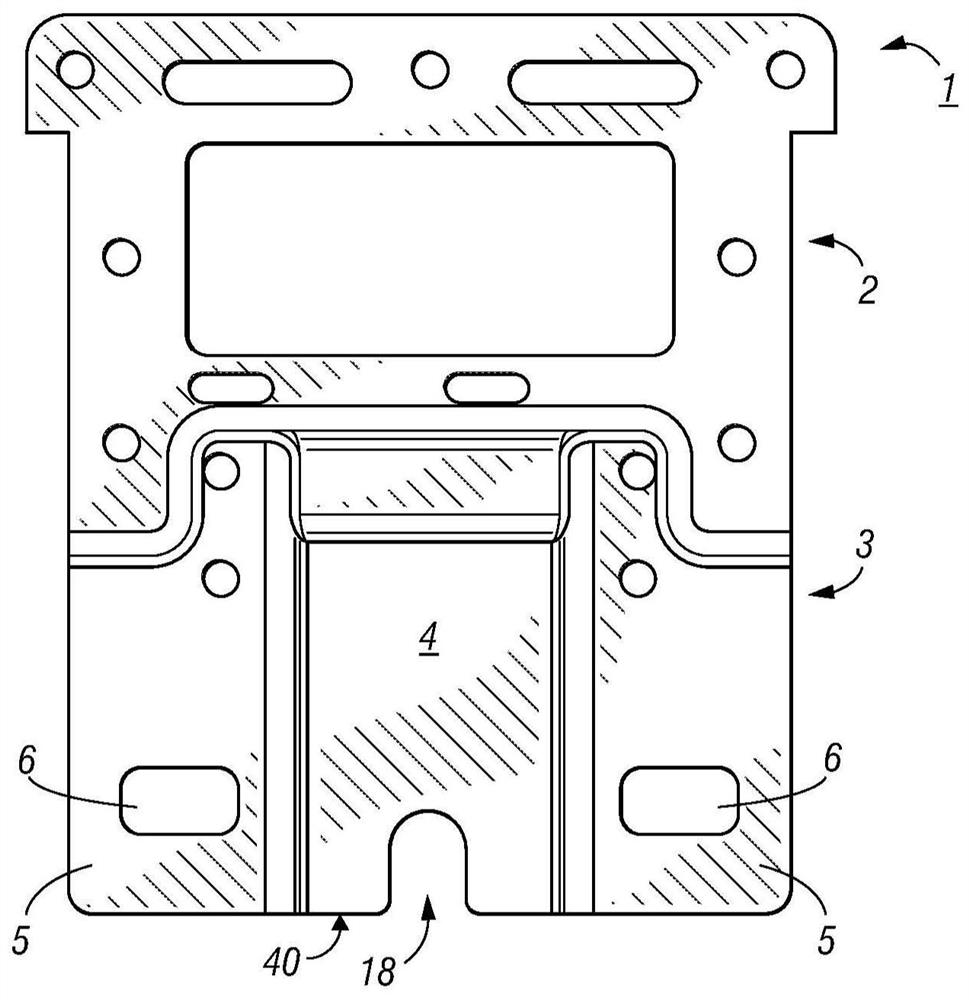

[0041] As mentioned above, if the connection between the thin panel and the support arm is not strong enough, the connection to the edge of the support arm may break. For clarity, a robust connection includes, among others, the following properties:

[0042] 1) Sufficient strength - eg not to bend (permanently deform) or break.

[0043] 2) Sufficient stiffness - low deflection under torque and lateral forces required to reconfigure any movable joints in the fixture (eg to rotate a lighting module or change an elbow joint). In other words, the electrical connection between the lighting module and the rest of the fixture will not be affected by the force necessary to adjust any movable part of the rest of the fixture.

[0044] Also, under these conditions, any deflection that occurs within the electrical components must be small enough that they cannot be damaged by bending (eg, electrical traces cannot be damaged).

[0045] 3) When shock occurs, it will not swing or vibrate. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com