Soft-body robot variable-rigidity joint module

A joint module and variable stiffness technology, applied in the field of robotics, can solve the problems of weak load capacity and insufficient stiffness of soft robots, and achieve the effect of good environmental adaptability and large load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

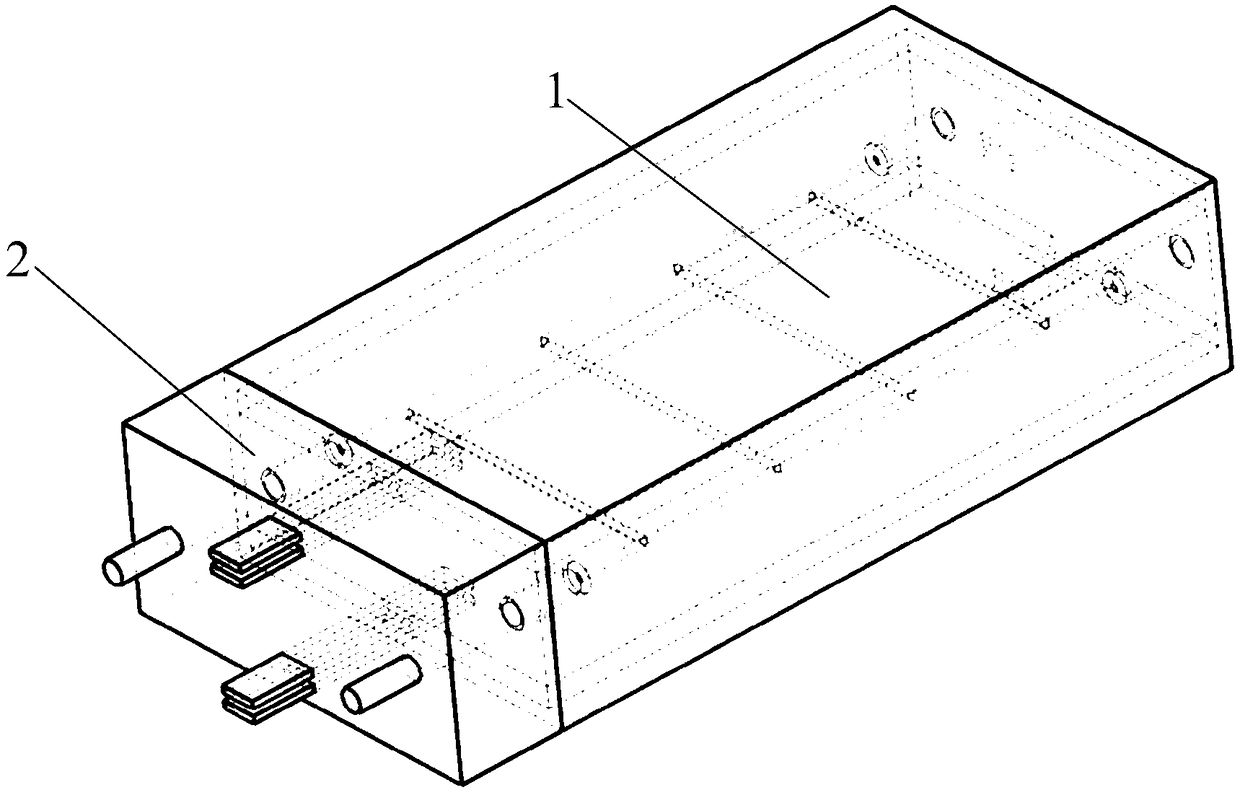

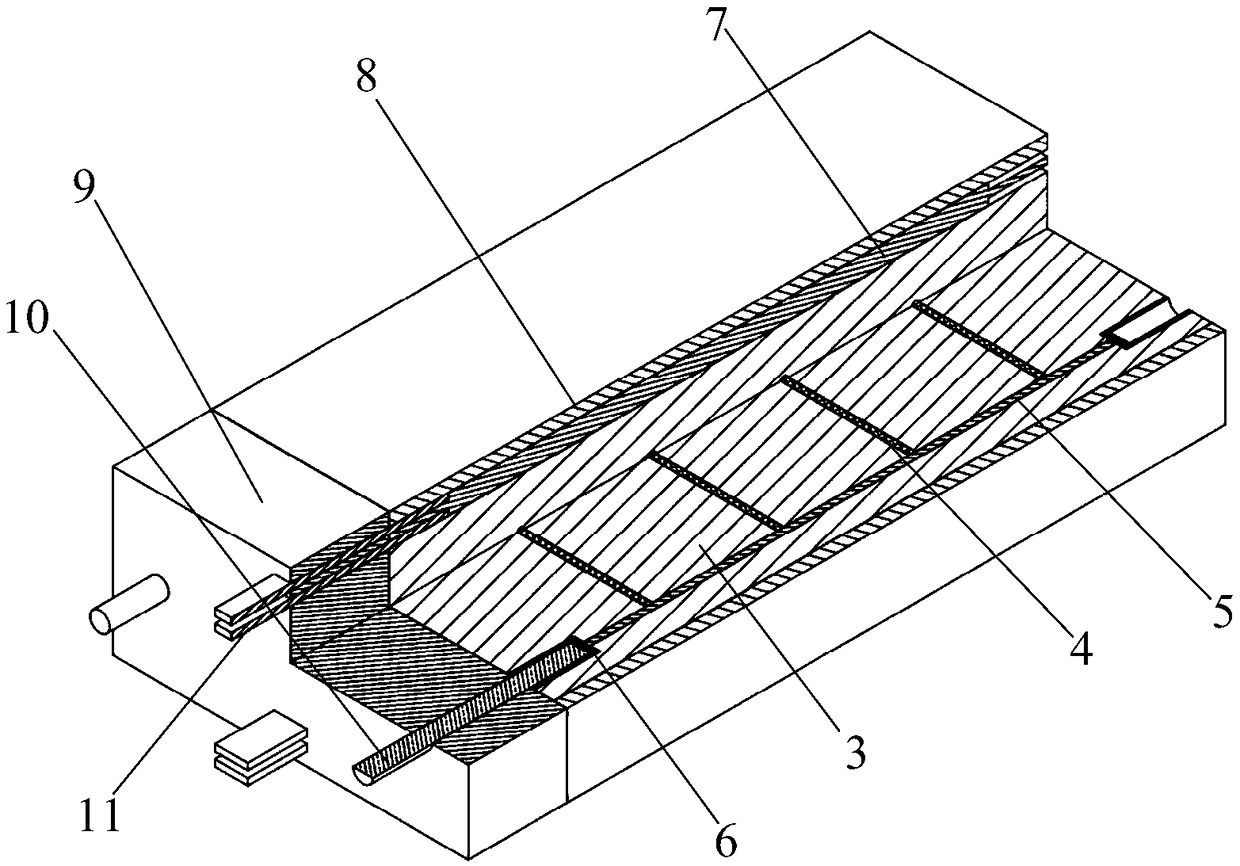

[0036] refer to Figure 1-7 , the variable stiffness joint module of the soft robot in this embodiment includes an active deformation part 1 and a connecting part 2 .

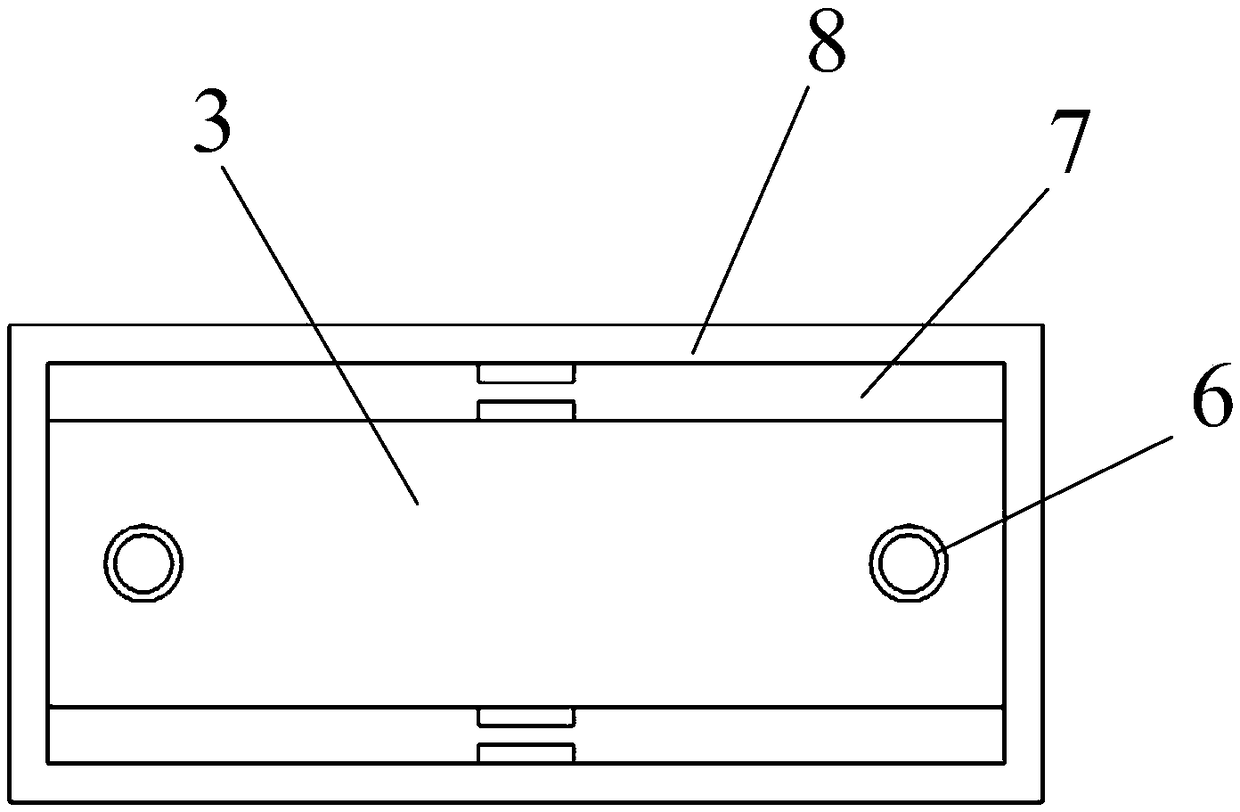

[0037] The active deformation part 1 includes a heat-sensitive SMP variable-stiffness elastic matrix 3 , a flexible heating circuit 12 , an EAP software driver 7 and an elastic constrained layer 8 .

[0038] The cross-section of the SMP variable stiffness elastic matrix 3 is preferably rectangular, and the material of the heat-sensitive SMP variable stiffness elastic matrix 3 is preferably an SMP material with a low glass transition temperature. The SMP material can be formed by 3D printing, and the heat-sensitive SMP variable stiffness elastic matrix 3 is embedded Flexible heating circuit 12.

[0039] The flexible heating circuit 12 includes several flexible heating wire units 4, two flexible wires 5 and four cylindrical terminals 6, the topology of the flexible heating circuit 12 is preferably a parallel str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com