AGV suspension elastic adjustment method and system

A technology of suspension system and adjustment method, which is applied in the direction of elastic suspension, suspension, vehicle spring, etc., which can solve the problems of large up and down vibration range of the trolley, frequent jumping of the trolley, and inability to realize the adjustment of the equivalent elastic coefficient, so as to achieve flexibility strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

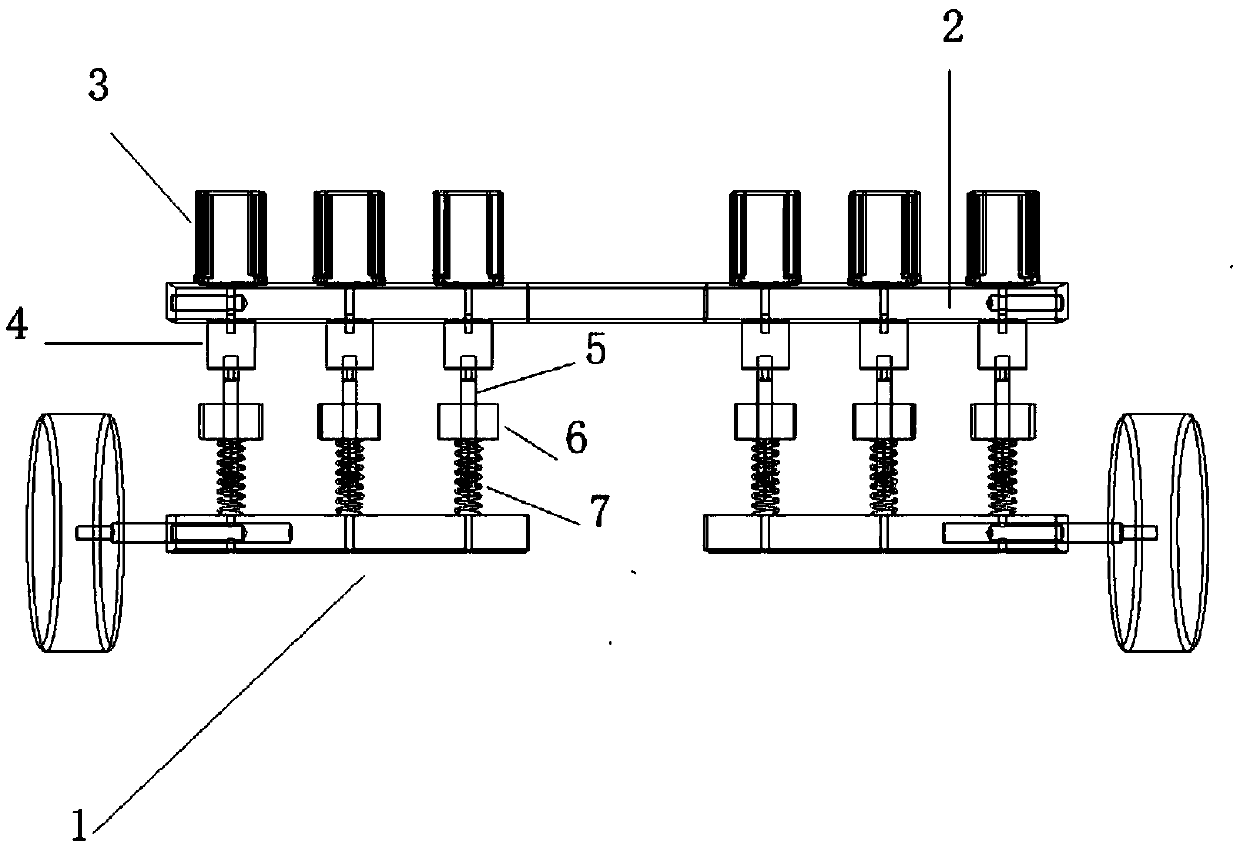

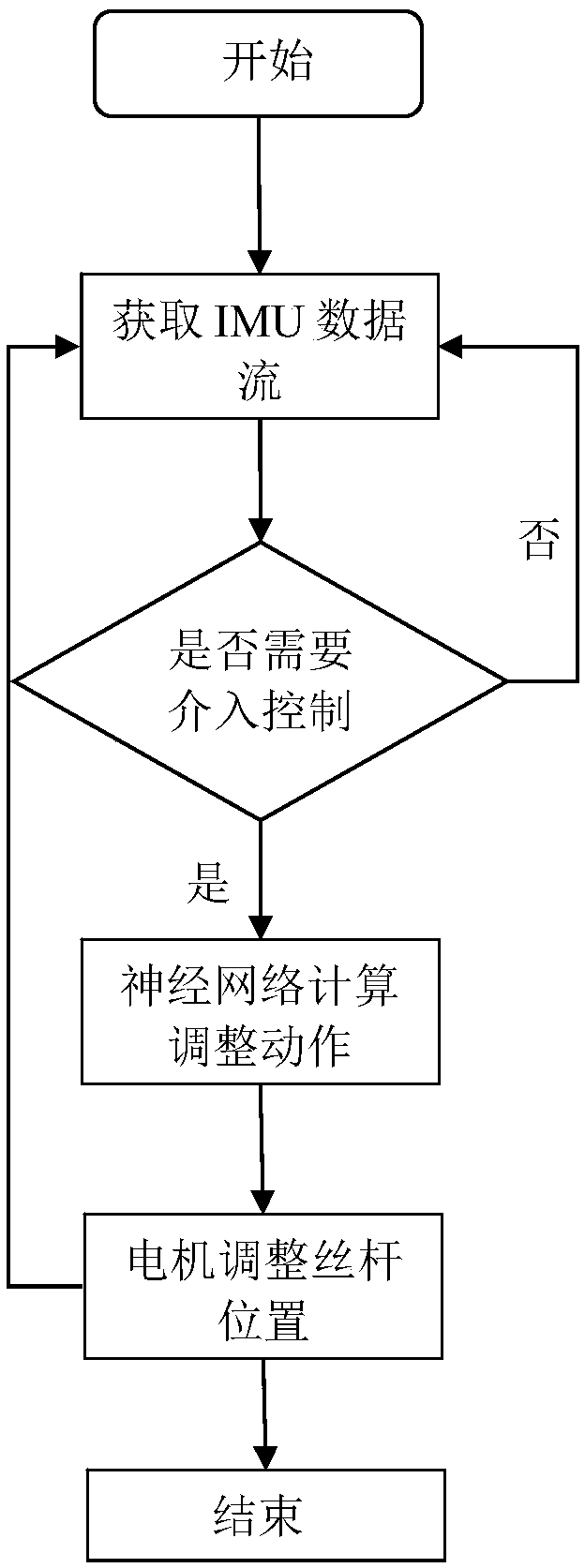

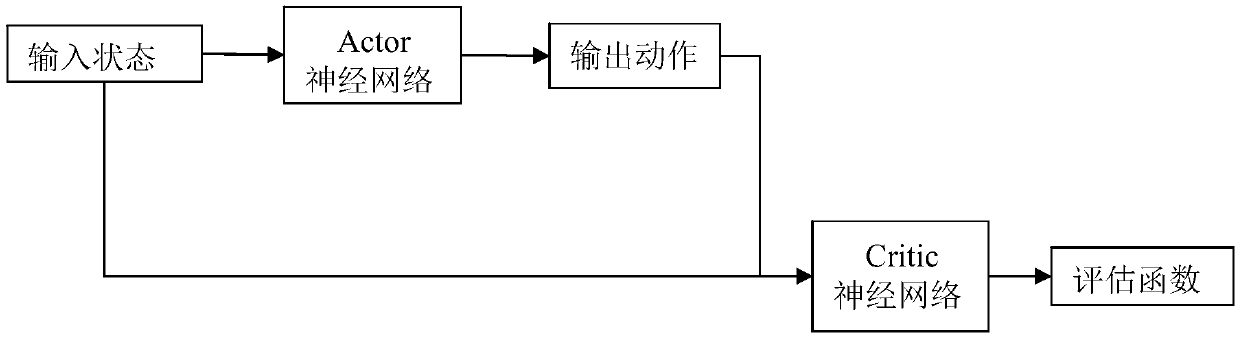

[0035] The purpose of the present invention is to provide an electronically controlled elastic unit with adjustable spring combination stiffness, which can make the AGV suspension system elastically adjustable to adapt to different road conditions, and has the characteristics of wide elastic adjustment range and strong real-time performance. At present, the suspension system commonly used by AGV is a passive spring damping, which cannot be adjusted elastically. If a parallel structure of multiple springs is used, and each spring can independently control its compression to form an elastic unit system, the elastic unit system composed of multiple springs working together has the biggest advantage that the equivalent elastic coefficient can be adjusted, and the spring The more, the greater the adjustable range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com