Hall thrusters suitable for working in a wide parameter range

A Hall thruster and parameter technology, applied in the field of aerospace electric propulsion, to achieve the effects of improving ionization efficiency and working medium utilization, expanding stable working area, and improving performance under variable working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

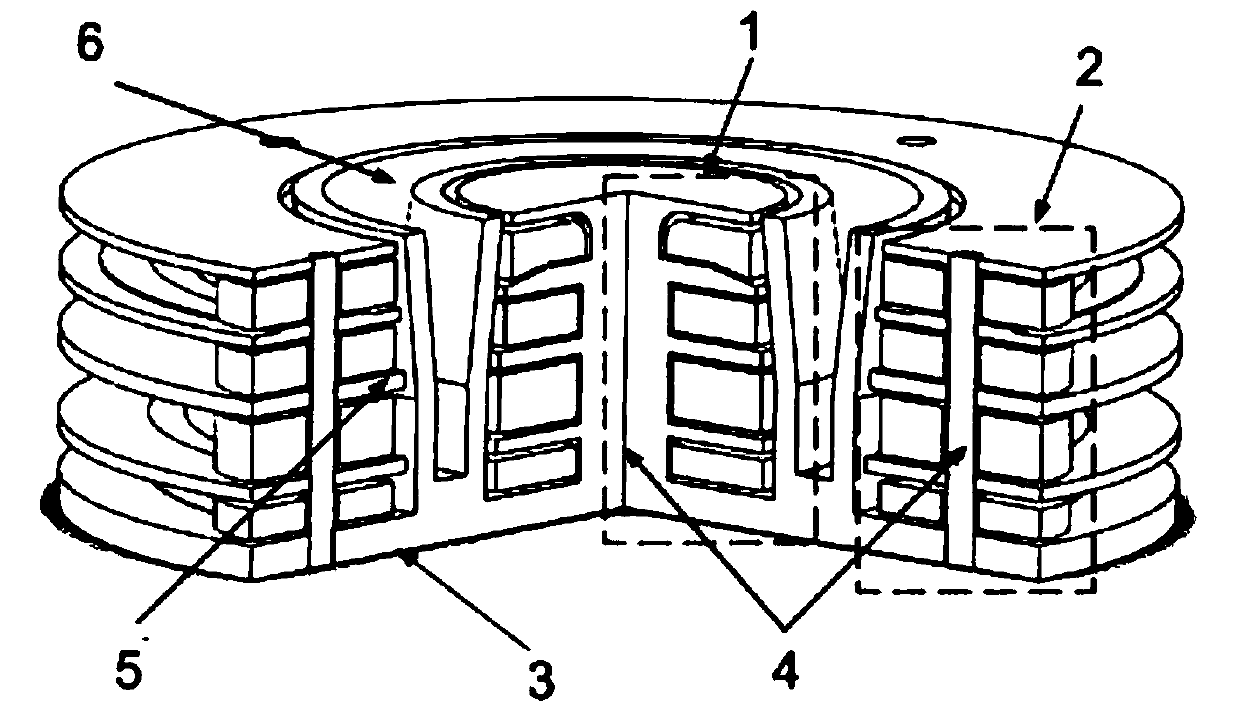

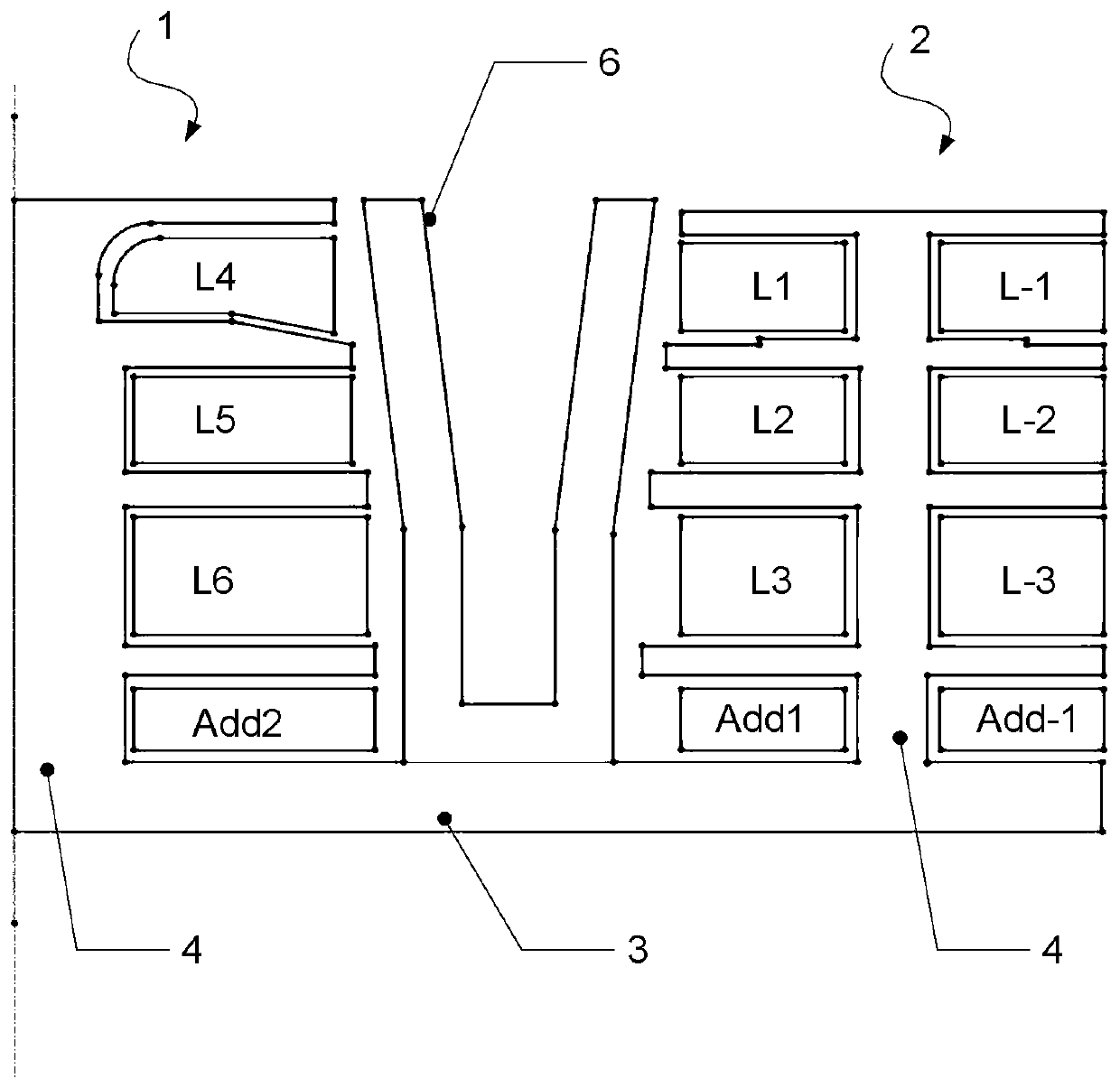

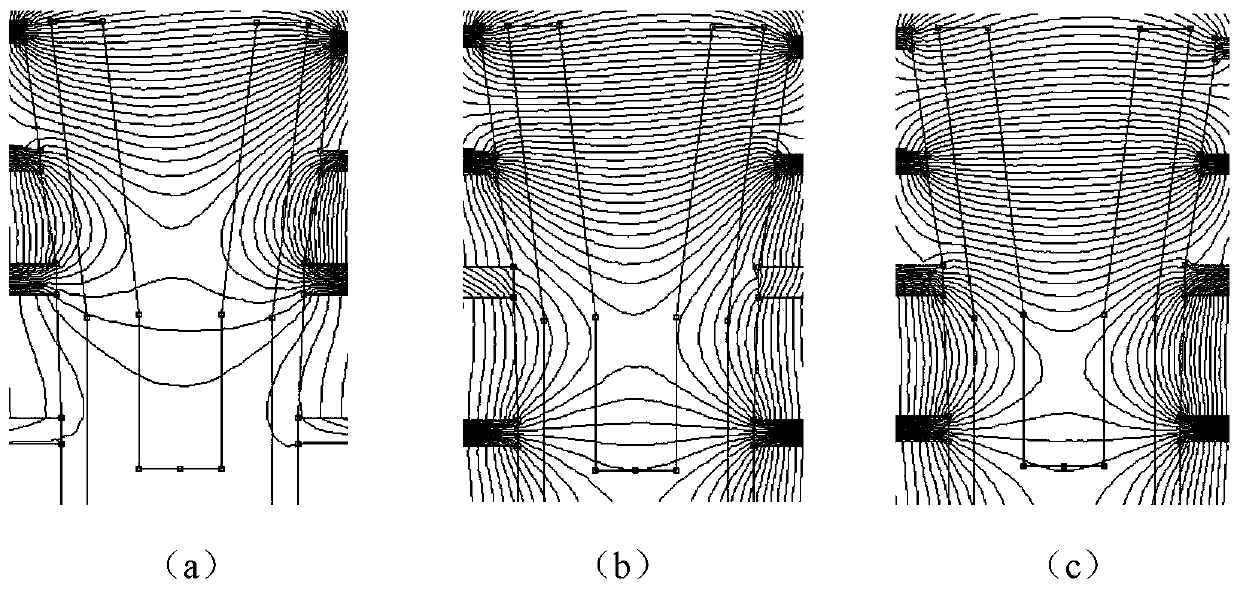

[0030] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention. It should be noted that, as long as there is no conflict, each embodiment and each feature in each embodiment of the present invention can be combined with each other, and the formed technical solutions are all within the protection scope of the present invention.

[0031] The high-efficiency ionization of the propellant working fluid is the basis for ensuring the stable and high-efficiency work of the Hall thruster. The ionization process mainly refers to the process in which a neutral gas is ionized into ions during the collision with electrons with a certain energy. For the Hall thruster, the distribution of the ionization process in the discharge channel is a self-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com