Bearing cooling water flow condition monitoring device

A monitoring device and cooling water technology, applied in the components of the pumping device for elastic fluid, pump control, non-variable-capacity pump, etc., can solve the problems of dust removal fan bearing damage, low work efficiency, damage to fan bearing bushes, etc. , to achieve the effect of improving reliability and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

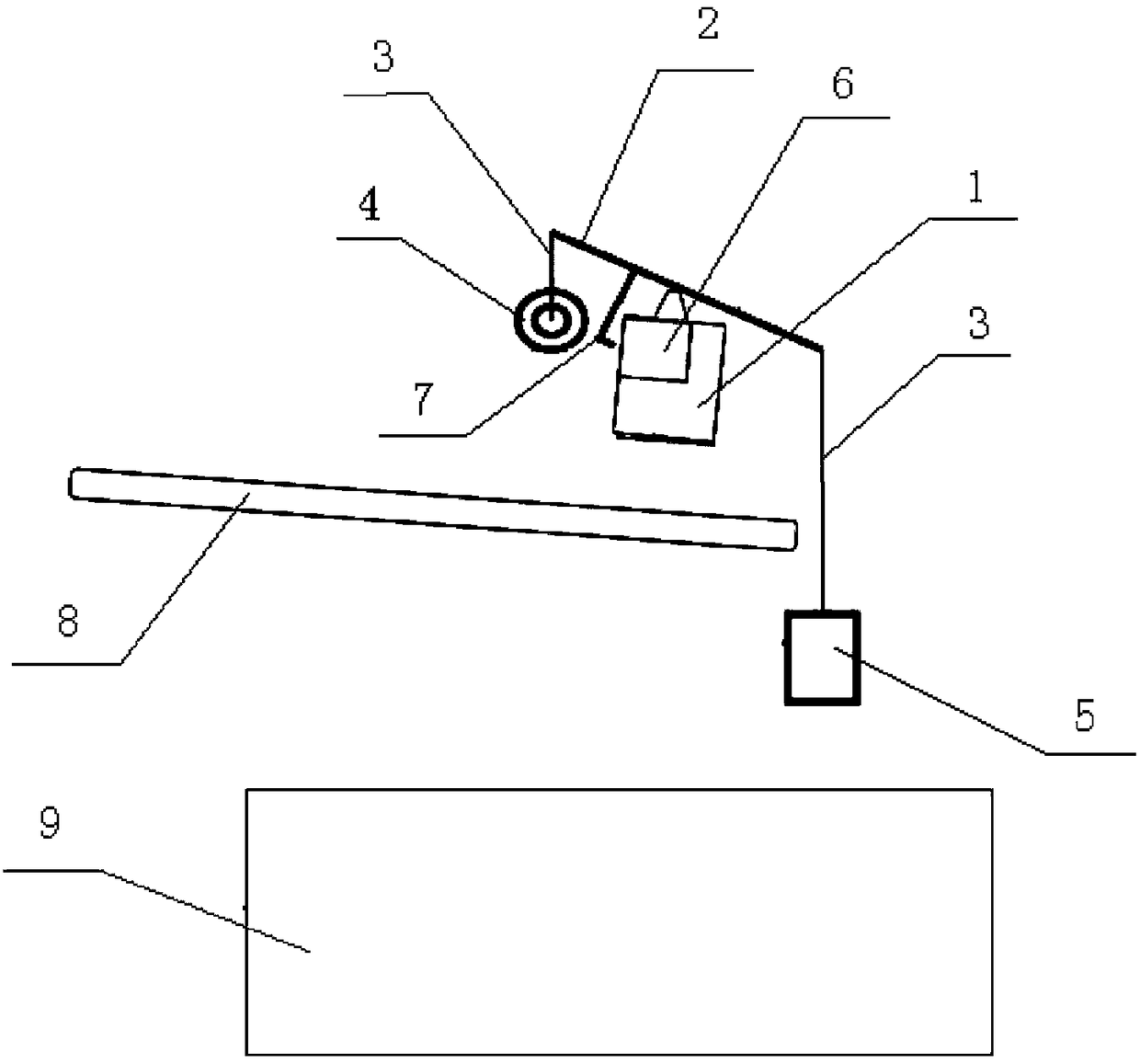

[0010] Such as figure 1 As shown, a bearing cooling water flow monitoring device includes a support frame 1, a balance beam 2, a suspension wire 3, a counterweight 4, a water collection bucket 5, a travel switch 6, a flashing light and a trigger lever 7. The support frame 1 is rotationally connected to the middle of the balance beam 2, the counterweight 4 and the water collection bucket 5 are respectively installed on both ends of the balance beam 2 through the hanging wire 3, and the travel switch 6 is installed on The side of the support frame 1, the flashlight is connected with the travel switch 6, the trigger lever 7 is installed on the balance beam 2 near the side of the counterweight 4, the trigger lever 7 The end faces the travel switch 6; the bottom of the water collection bucket 5 is provided with a mesh, the cooling water in the cooling water recovery pipe 8 flows into the water collection bucket 5, and the water collection bucket 5 is placed in the cooling water tan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap