A self-lubricating sliding bearing with full-life surface texture

A surface texture, sliding bearing technology, used in shafts and bearings, bearing components, mechanical equipment, etc., can solve the problems of high processing difficulty and replacement cost, unadjustable gap between shaft and bearing bush, high difficulty and cost, and improve the production Efficiency and success rates, reduced manufacturing costs, reduced maintenance and replacement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

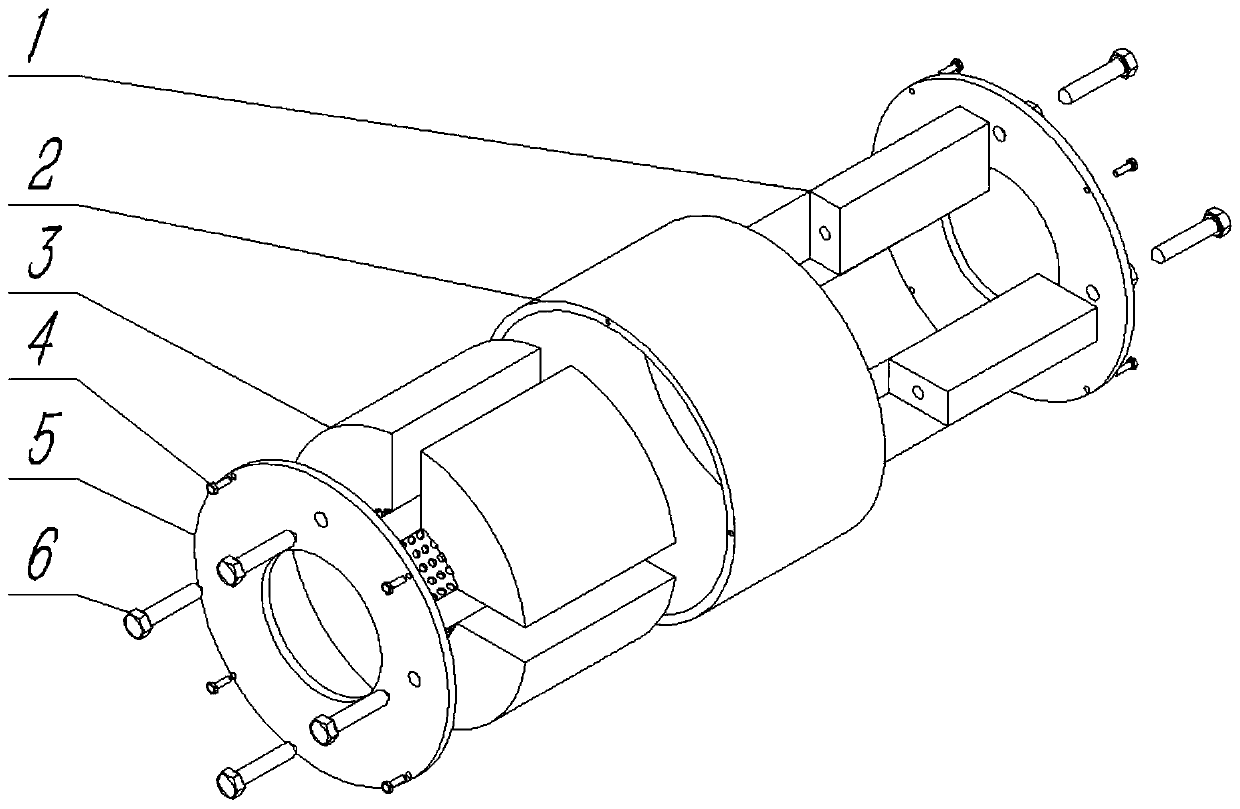

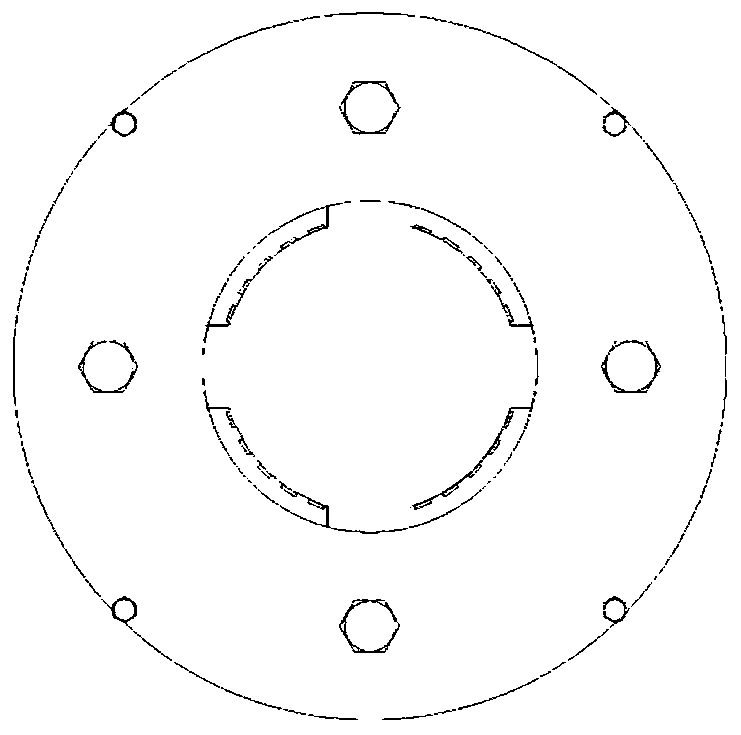

[0041] Such as Figure 1 to Figure 3 As shown, this embodiment provides a self-lubricating sliding bearing with a full-life surface texture, including an inner support frame 1, an outer support cover 2, a split bearing bush 3, an end cover hexagon socket bolt 4, an end cover 5, Support frame inner hexagon bolt 6. Among them: the inner hexagonal bolt 4 of the end cover is the inner hexagonal bolt used to fix the left and right end covers 5 and the outer support cover 2, which is a standard part; Hexagon socket bolts are standard parts.

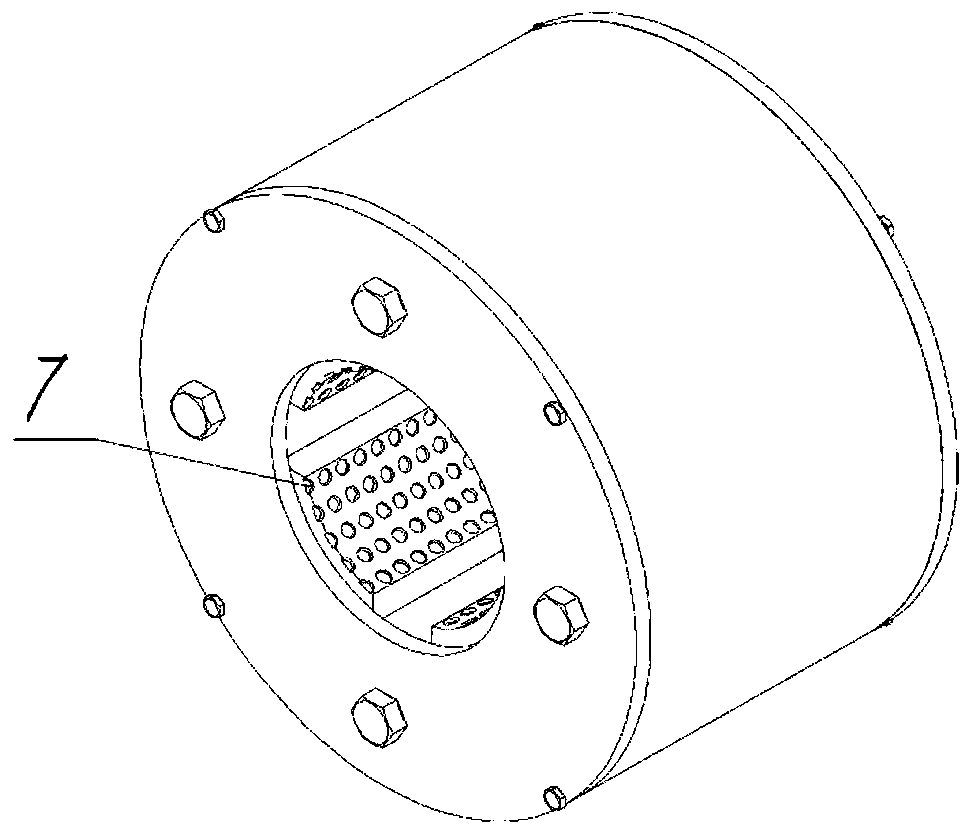

[0042] Such as Figure 4 and Figure 5As shown, the internal support frame 1 includes four rectangular parallelepiped structures uniformly distributed in the radial direction, and the two ends of the rectangular par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com