Lightning rod liquid collision type damping system

A technology of damping system and lightning rod, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., can solve the problems of low damping efficiency of frequency modulation mass damper, high cost of fixed equipment, unsatisfactory damping effect, etc., and achieve design Novel ideas, simple structure, and improved damping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

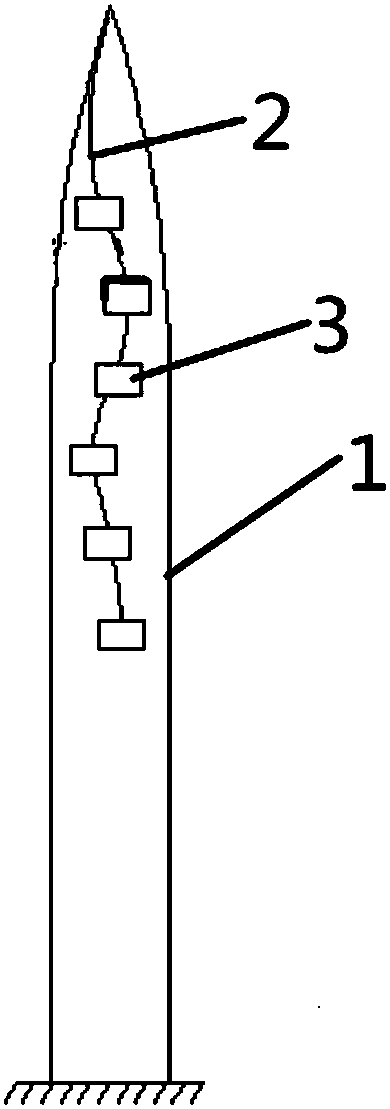

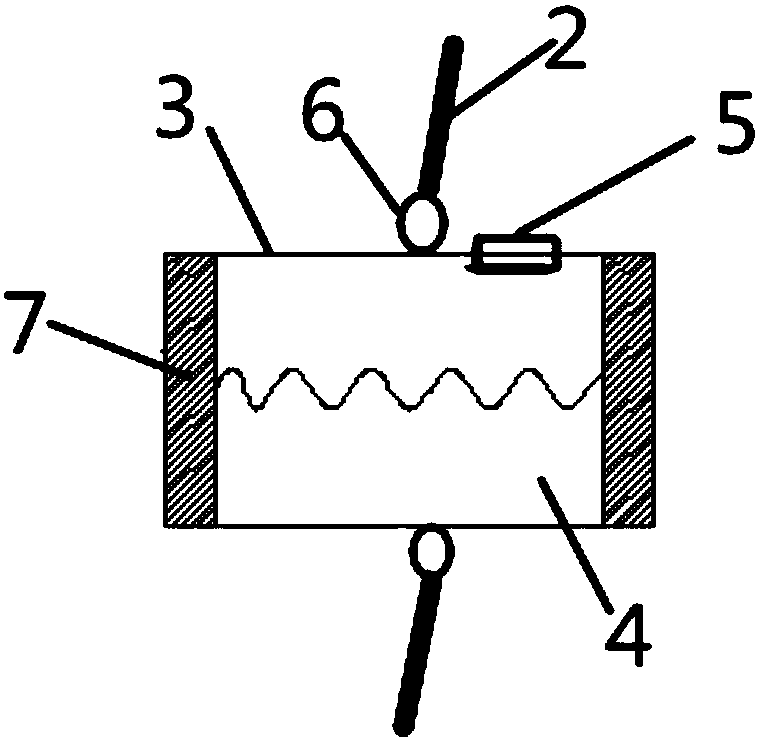

[0031] The present invention provides a liquid collision damping system for a lightning rod. The lightning rod 1 is in the form of a conical shell, and the damping system is arranged in the shell; the damping system includes a damping rope 2 connected to the upper end of the shell. And a damping container connected to the lower end of the damping rope 2; a liquid damping medium 4 is arranged in the damping container.

[0032] The damping container includes six damping boxes 3, which are sequentially connected by damping ropes 2; each of the damping boxes 3 is respectively provided with a liquid damping medium 4.

[0033] The liquid damping medium 4 includes antifreeze.

[0034] The volume of the damping medium 4 in the damping box 3 is 30-60% of the volume of the damping box 3 .

[0035] The upper end of the damping box body 3 is provided with an opening, and a piston 5 screwed therein is provided in the opening.

[0036] The upper end and the lower end of the damping box bo...

Embodiment 2

[0046] The structure of this embodiment is the same as that of Embodiment 1, except that the materials of the housing and the damping box are as follows:

[0047] The housing includes the following components in parts by mass:

[0048] Cu: 0.35%, Mn: 1.5%, Fe: 0.4%, Si: 0.11%, Ti: 0.001%, B: 0.003%, RE: 0.05%, the balance is Al and impurities, and impurities ≤ 0.1%;

[0049] The damping box includes the following components by mass fraction:

[0050] C: 2%; N: 3%, In: 1%, Pd: 0.1%, Zr: 0.1%, Ir: 0.5%, Rh: 0.2%, Fe: 30%.

[0051] The material of the housing and the damping box provided in this embodiment can ensure the stability of the structure, guarantee the damping effect of the damping system, and greatly increase the service life.

Embodiment 3

[0053] The structure of this embodiment is the same as that of Embodiment 1, except that the materials of the housing and the damping box are as follows:

[0054] The housing includes the following components in parts by mass:

[0055] Cu: 0.20%, Mn: 1.0%, Fe: 0.3%, Si: 0.95%, Ti: 0.008%, B: 0.018%, RE: 0.20%, the balance is Al and impurities, and impurities ≤ 0.1%;

[0056] The damping box includes the following components by mass fraction:

[0057] C: 1%; N: 2%, In: 0.8%, Pd: 0.06%, Zr: 0.7%, Ir: 1.0%, Rh: 2%, Fe: 40%.

[0058] The material of the housing and the damping box provided in this embodiment can ensure the stability of the structure, guarantee the damping effect of the damping system, and greatly increase the service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com