Rapid heat dissipating type gearbox housing

A gearbox and fast technology, applied in the field of gearboxes, can solve the problems of changing the size of transmission components, reducing the quality of control, affecting meshing, etc., to achieve the effects of increasing stability, increasing shell volume, and accelerating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

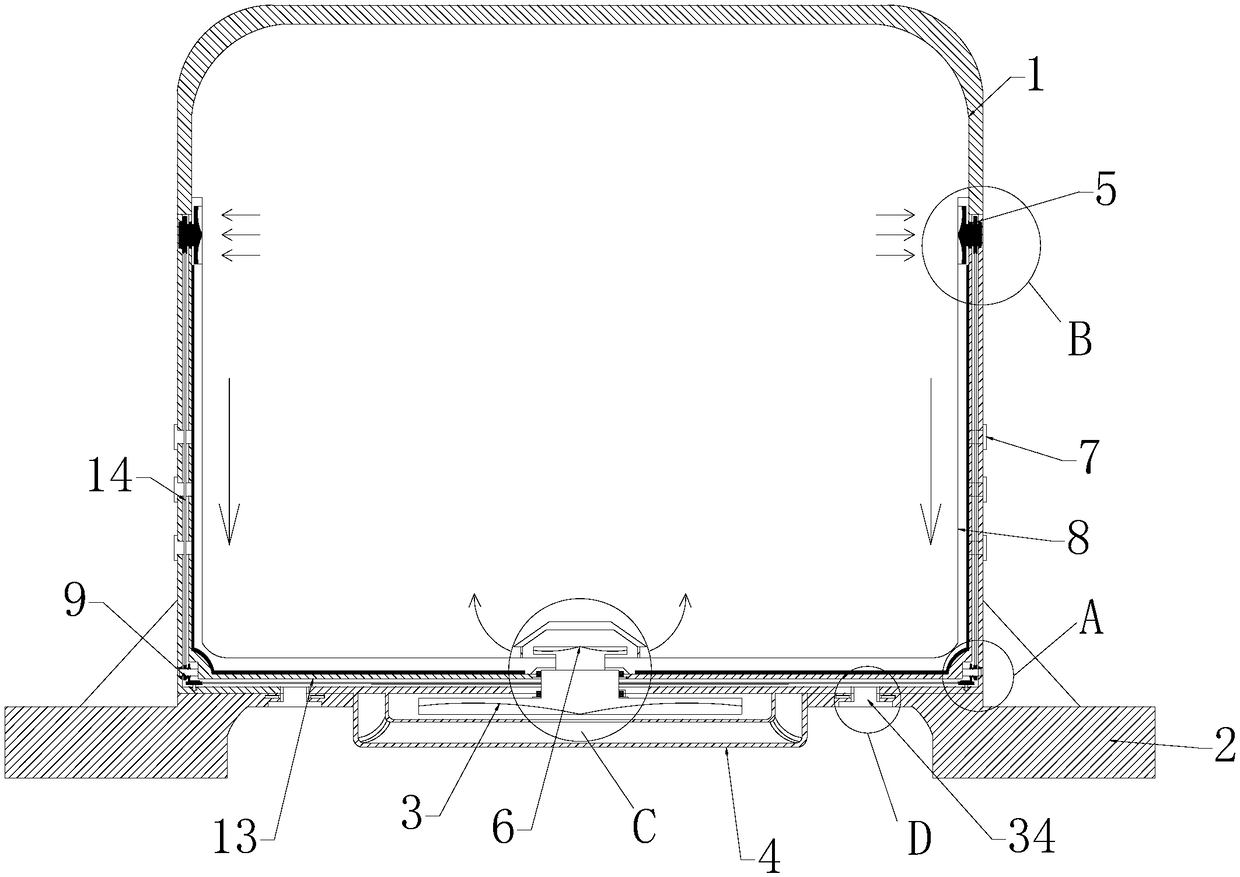

[0029] This embodiment provides a gearbox case for rapid heat dissipation, including a case body 1, a base 2, and a heat dissipation assembly, wherein:

[0030] The base 2 is composed of left and right seats, the left and right seats are fixedly connected to the left and right sides of the bottom of the shell body 1 respectively, and the base 2 is fixedly installed on the upper end of the longitudinal beam of the vehicle body;

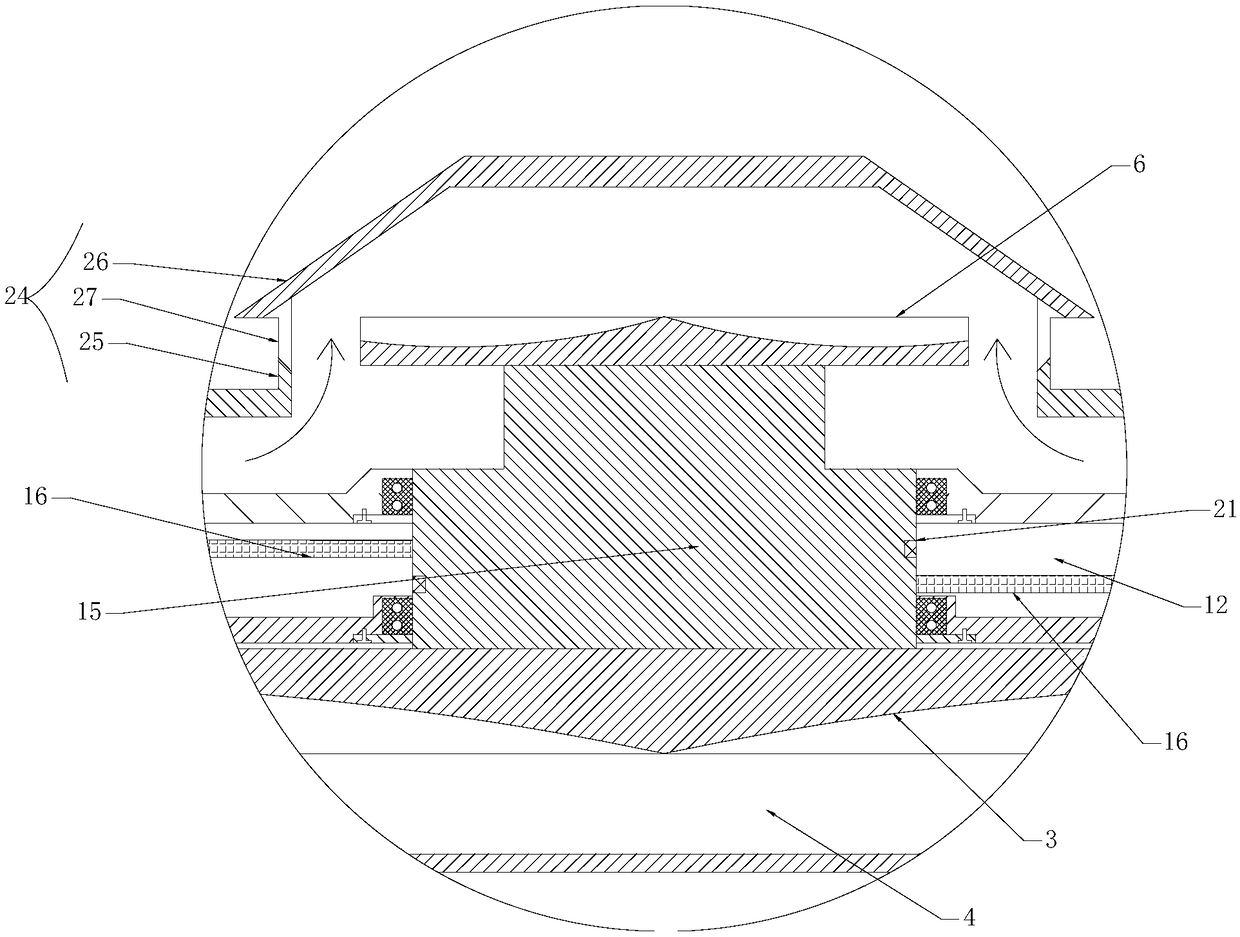

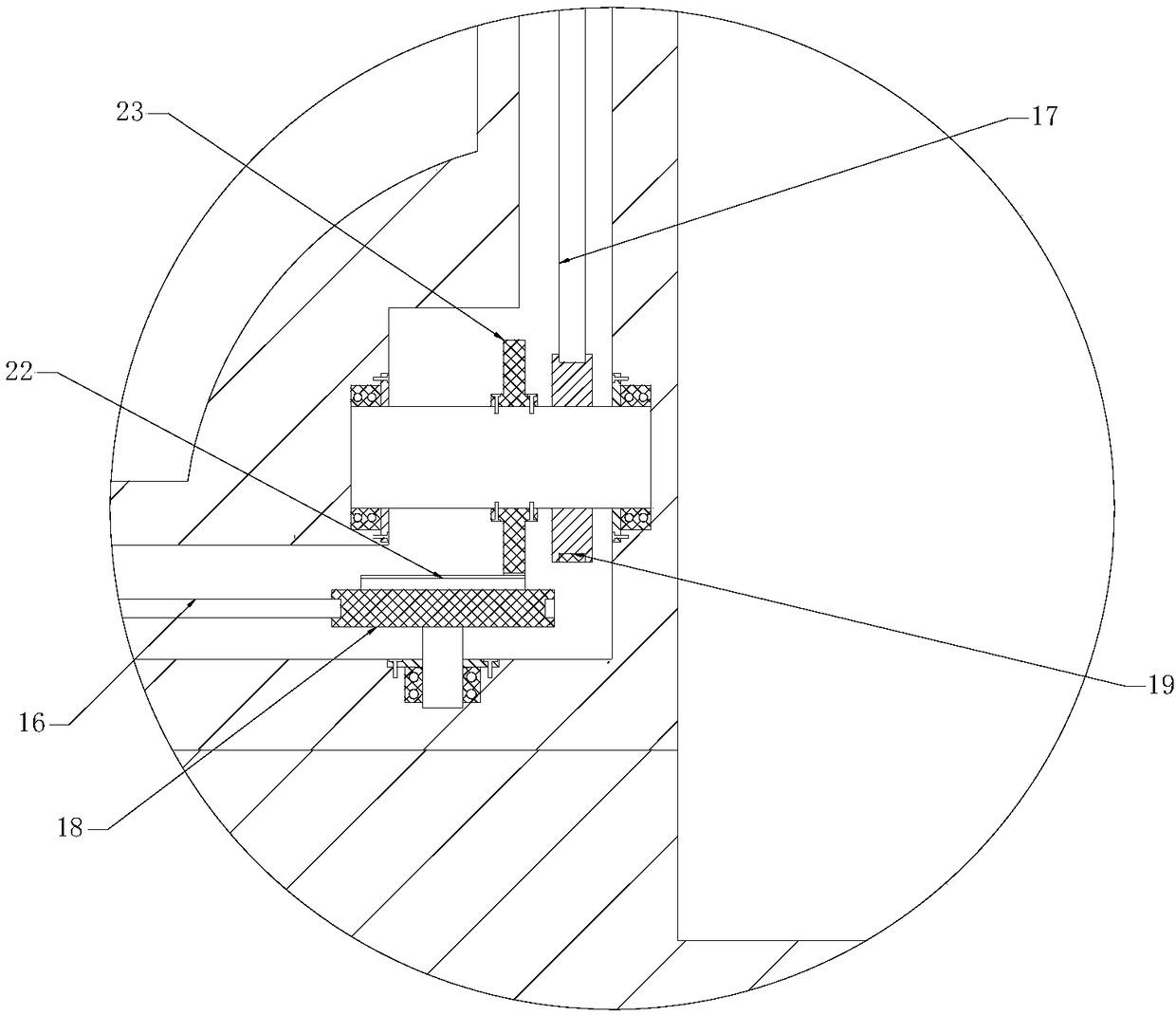

[0031] The heat dissipation assembly includes a power fan 3, an acceleration air duct 4, a suction fan 5, an exhaust fan 6, a heat conduction assembly 7, an air delivery channel 8, and a transmission assembly 9. The acceleration air duct 4 is fixedly installed in the middle of the bottom of the shell body 1 to The area of the air inlet of the channel 4 is larger than the area of the air outlet. The power fan 3 is installed on the outer bottom of the shell body 1 and is located in the middle of the acceleration air channel 4. The air delivery channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com