Two-line type tube spirit level bubble offset quantity measurement method based on image processing technology

An image processing and tube level technology, which is applied to measuring devices, instruments, and optical devices, etc., can solve the problems of large error, time-consuming and laborious human eye recognition, etc., and achieve the effect of high precision and better robustness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

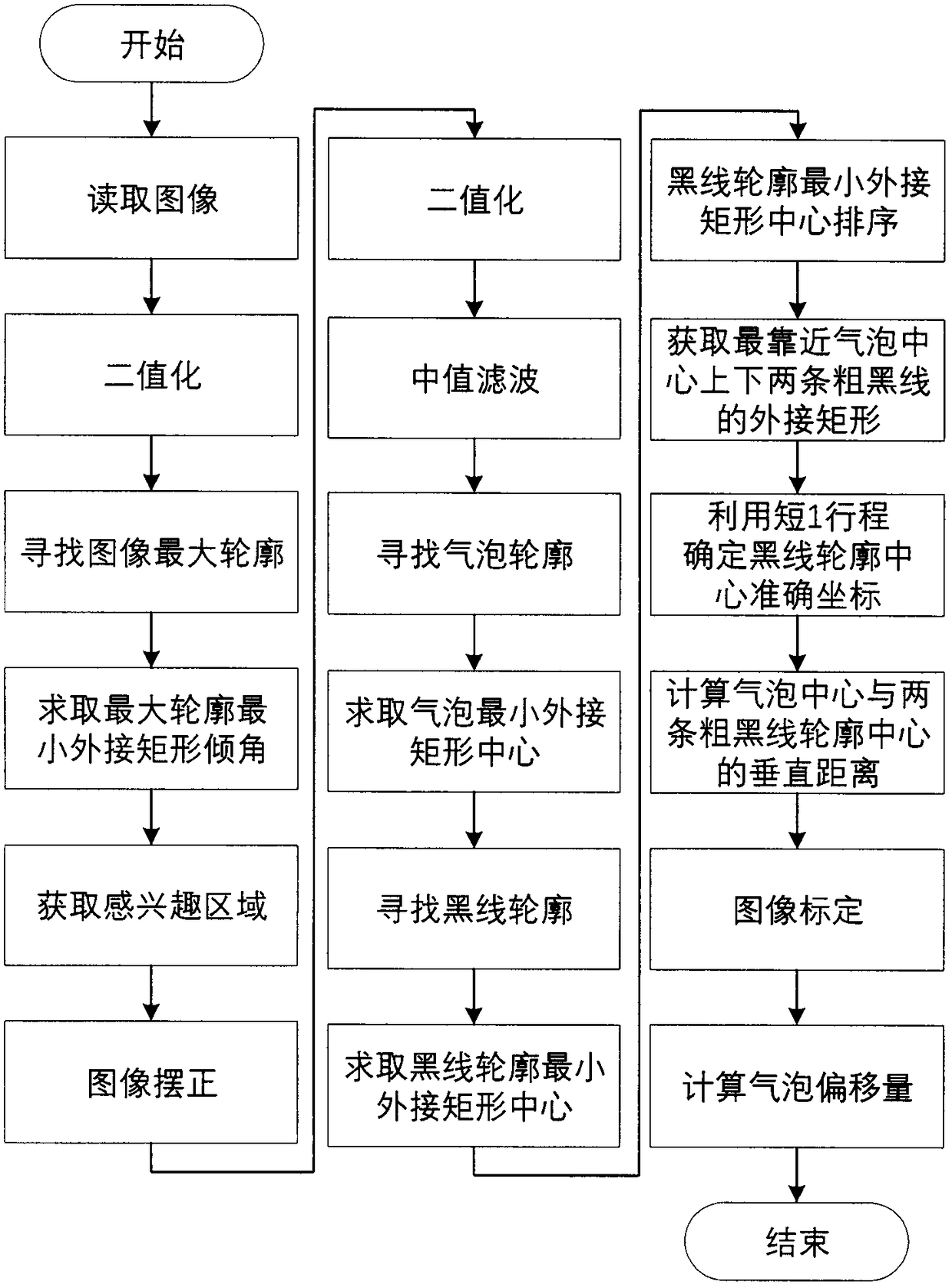

[0029] Such as figure 1 Shown, the step of the inventive method is:

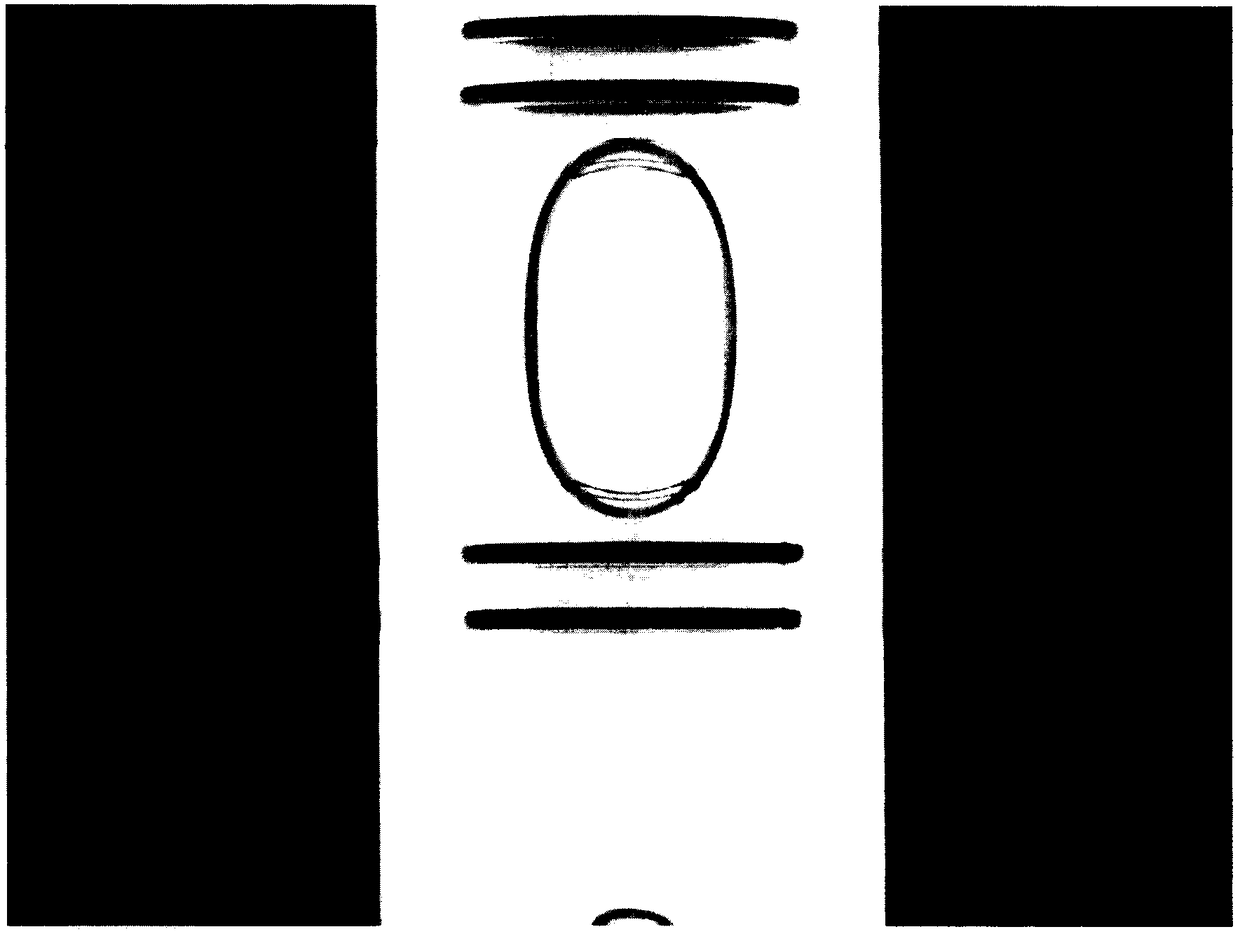

[0030] Step 1: Read the original grayscale image of the bubble in the two-line vial

[0031] The original grayscale image src of the obtained two-line vial bubble is as follows: figure 2 shown.

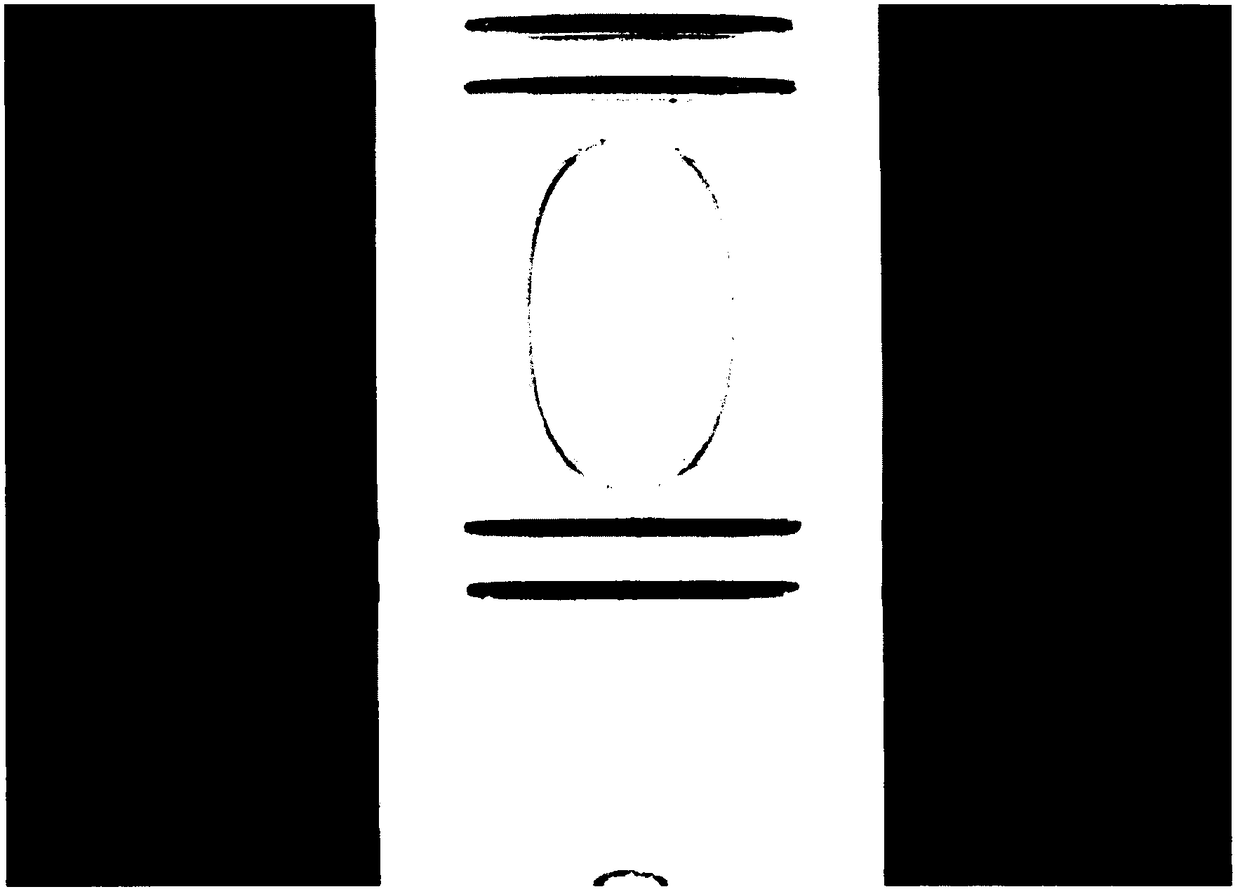

[0032] Step 2: Binarize the original grayscale image

[0033] The binarized image bI obtained by binarizing and segmenting the original grayscale image src using the OTSU method 1 Such as image 3 shown.

[0034] Step 3: Perform contour detection on the binarized image, find the largest contour in the image and calculate the inclination angle of the smallest circumscribed rectangle of the largest contour

[0035] For the image bI obtained after binarization 1 For contour detection, since the foreground image and the background image are significantly different after binarization, and the background image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com