Artificial gastric body internal squeezing force measuring method

A technology of extrusion force and manual, applied in the field of measurement, can solve the problems affecting the research results, unable to effectively measure the internal extrusion force of the artificial stomach body, comparison, etc., and achieve the effect of real measurement results, real and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

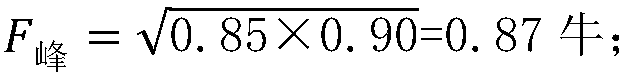

[0030] Step 1. Use agar as the gelling agent, use different coloring agents as dyes, use ultrapure water as the solvent, use the texture analyzer test results as the standard, and use the gel ball with a tolerance of 0.20 N as the basis to fix the resistance. The force of 0.05 N is used as the difference, and the standard tolerance is prepared in an equal increasing manner. The standard tolerances are 0.25 N, 0.30 N, 0.35 N, 0.40 N, 0.45 N, 0.50 N, 0.55 N, 0.60 N, 0.65 N, and 0.70 N , 0.75 cattle, 0.80 cattle, 0.85 cattle, 0.90 cattle, 0.95 cattle, 1.00 cattle, 1.05 cattle, 1.10 cattle gel balls, and dye each gel ball with a different color.

[0031] Step 2: Add 1 gram of pepsin, 1.5 grams of gastric mucin and 8.775 grams of sodium chloride in 1000 milliliters of ultrapure water in sequence, stir evenly, and then add 6 mol / liter of hydrochloric acid to adjust the pH to 1.3.

[0032] Step 3: Boil 1000ml of ultra-pure water, add 10g of guar gum, stir evenly, and keep warm at 37°...

Embodiment 2

[0043] Step 1. Use agar as the gelling agent, use different coloring agents as dyes, use ultrapure water as the solvent, use the texture analyzer test results as the standard, and use the gel ball with a tolerance of 0.20 N as the basis to fix the resistance. The force of 0.10 N is used as the difference, and the standard tolerance is prepared in an equal increasing manner. The standard tolerances are 0.30 N, 0.40 N, 0.50 N, 0.60 N, 0.70 N, 0.80 N, 0.90 N, 1.00 N, 1.10 N, 1.20 N , 1.30 cattle gel balls, and dye each gel ball with different colors.

[0044] Step 2: Add 1 gram of pepsin, 1.5 grams of gastric mucin and 8.775 grams of sodium chloride in 1000 milliliters of ultrapure water in sequence, stir evenly, and then add 6 mol / liter of hydrochloric acid to adjust the pH to 1.3.

[0045] Step 3: Boil 1000ml of ultra-pure water, add 10g of guar gum, stir evenly, and keep warm at 37°C to obtain a simulated food viscosity fluid;

[0046] Step 4. Put the simulated food viscosity...

Embodiment 3

[0056] Step 1. Use agar as the gelling agent, use different coloring agents as dyes, use ultrapure water as the solvent, use the texture analyzer test results as the standard, and use the gel ball with a tolerance of 0.20 N as the basis to fix the resistance. The force of 0.15N is used as the difference, and the standard tolerance is prepared in an equal increment method: 0.35N, 0.50N, 0.65N, 0.80N, 0.95N, 1.10N, 1.25N, 1.40N, 1.55N, 1.70N gel balls and dye each gel ball a different color.

[0057] Step 2: Add 1 gram of pepsin, 1.5 grams of gastric mucin and 8.775 grams of sodium chloride in 1000 milliliters of ultrapure water in sequence, stir evenly, and then add 6 mol / liter of hydrochloric acid to adjust the pH to 1.3.

[0058] Step 3: Boil 1000ml of ultra-pure water, add 10g of guar gum, stir evenly, and keep warm at 37°C to obtain a simulated food viscosity fluid;

[0059] Step 4. Put the simulated food viscosity fluid prepared in step 3 into the artificial stomach, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com