Reagent cup clamping and reagent sucking and mixing synchronization device

A synchronization device and reagent cup technology, applied in the field of reagent cup clamping and reagent suction mixing synchronization device, can solve the problems of increased cost, low efficiency, manual detection can not keep up with intelligent detection, etc., and achieve the effect of easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

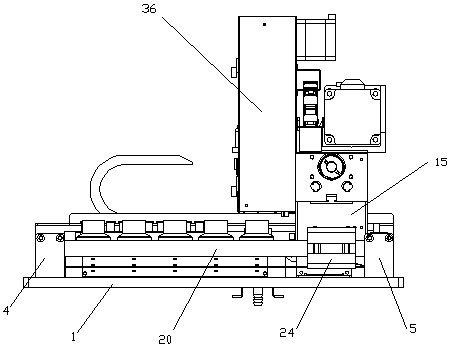

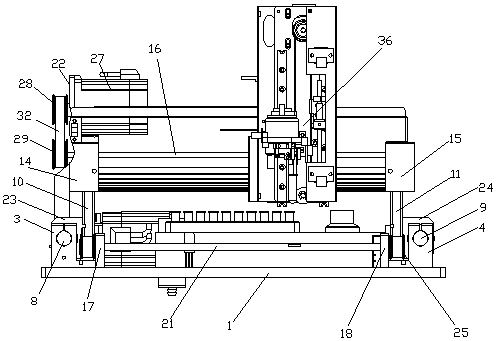

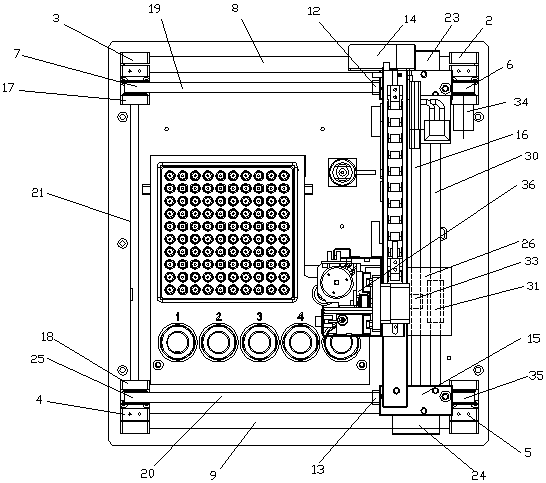

[0036] Such as Figure 1~4 As shown, a reagent cup clamping and reagent suction mixing synchronization device includes a base 1, a first fixed block 2, a second fixed block 3, a third fixed block 4, a fourth fixed block 5, a first driving wheel 6, The first driven wheel 7, left guide post 8, right guide post 9, left connecting plate 10, right connecting plate 11, left clamping plate 12, right clamping plate 13, left mount 14, right mount 15, screw mandrel 16, the first Bearing seat 17, second bearing seat 18, first belt 19, second belt 20, first rotating shaft 21, flower inlay, first guide block 23, second guide block 24, second driving wheel 25, fixed plate 26 , the second motor 27, the third driving wheel 28, the third driven wheel 29, the third guide post 30, the third guide block 31, the third belt 32, the screw nut 33, the first motor 34, the second driven wheel 35 , Synchronous clamping and mixing device 36 .

[0037] The first fixed block 2, the second fixed block 3,...

Embodiment 2

[0045] The synchronous pinching and mixing device 36 of this embodiment is different from the first embodiment, and other parts are the same as the first embodiment. Such as Figure 9 As shown, the synchronous clamping and mixing device 36 of the present embodiment includes a left baffle plate 3601, a right baffle plate 3603, a second mounting plate 3602, a fourth motor 3604, a fourth driving wheel 3605, a fourth belt 3606, and a fourth driven wheel 3607, left guide rail 3608, left slider 3610, left connecting seat 3611, right guide rail 3609, right slider 3631, right connecting seat 3643, third clamping plate 3629, fourth clamping plate 3635, third mounting plate 3650, fourth mounting plate 3665, the first installation block 3651, the fourth guide block 3657, the magnetic core 3652, the energized coil 3653, the guide rod 3669, the permanent magnet 3654, the right clamping plate 3620, the left clamping plate 3619, the fifth mounting plate 3658, the third Through hole 3667, mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com