Parallel motion mechanism adjusting device based on double-axis flexure hinge

A technology of flexible hinges and parallel motion, which is applied in the direction of photo-plate-making process exposure devices, photomechanical equipment, and photo-plate-making process of patterned surfaces. Improve stability and reliability, reduce sliding friction, and improve positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

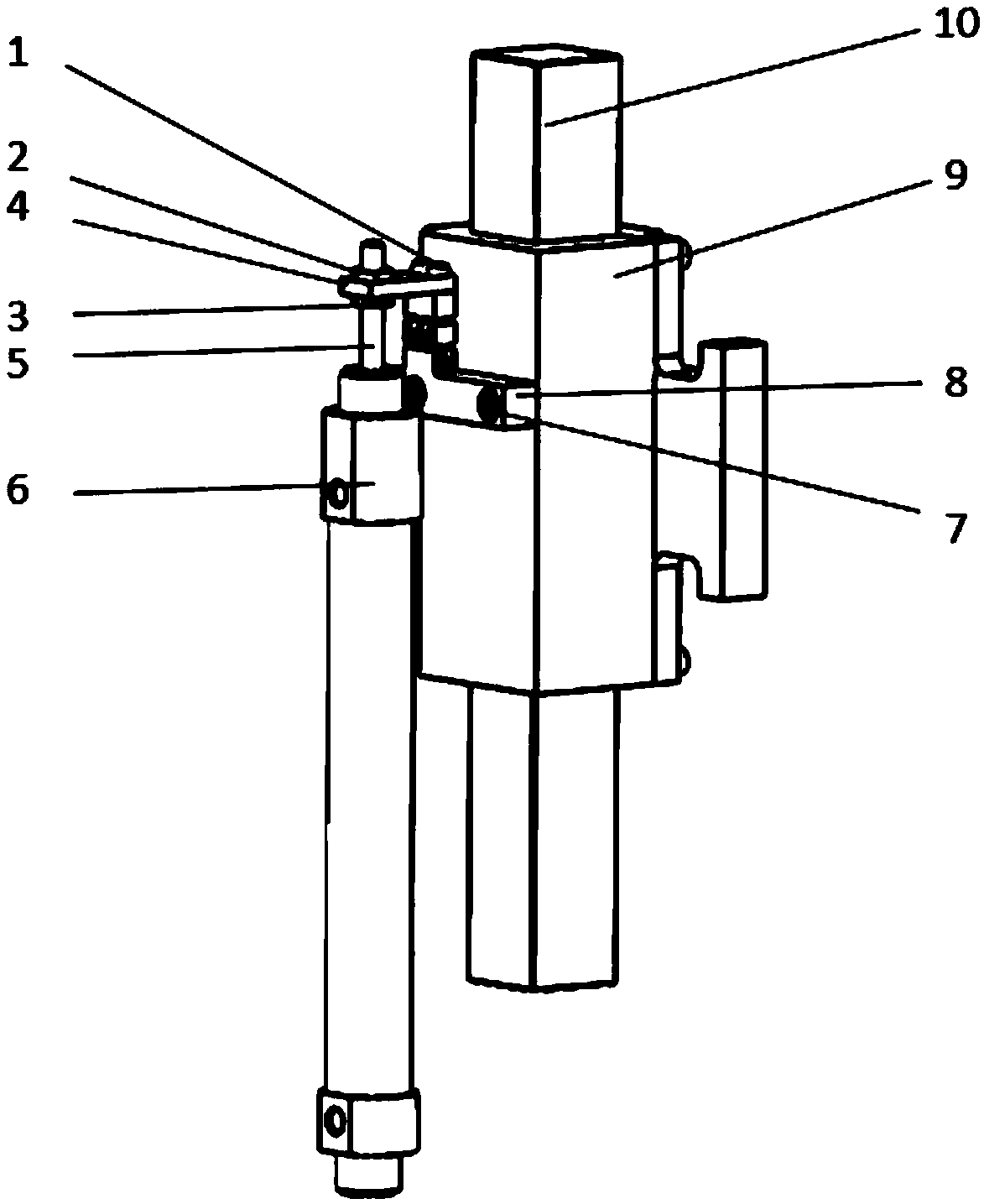

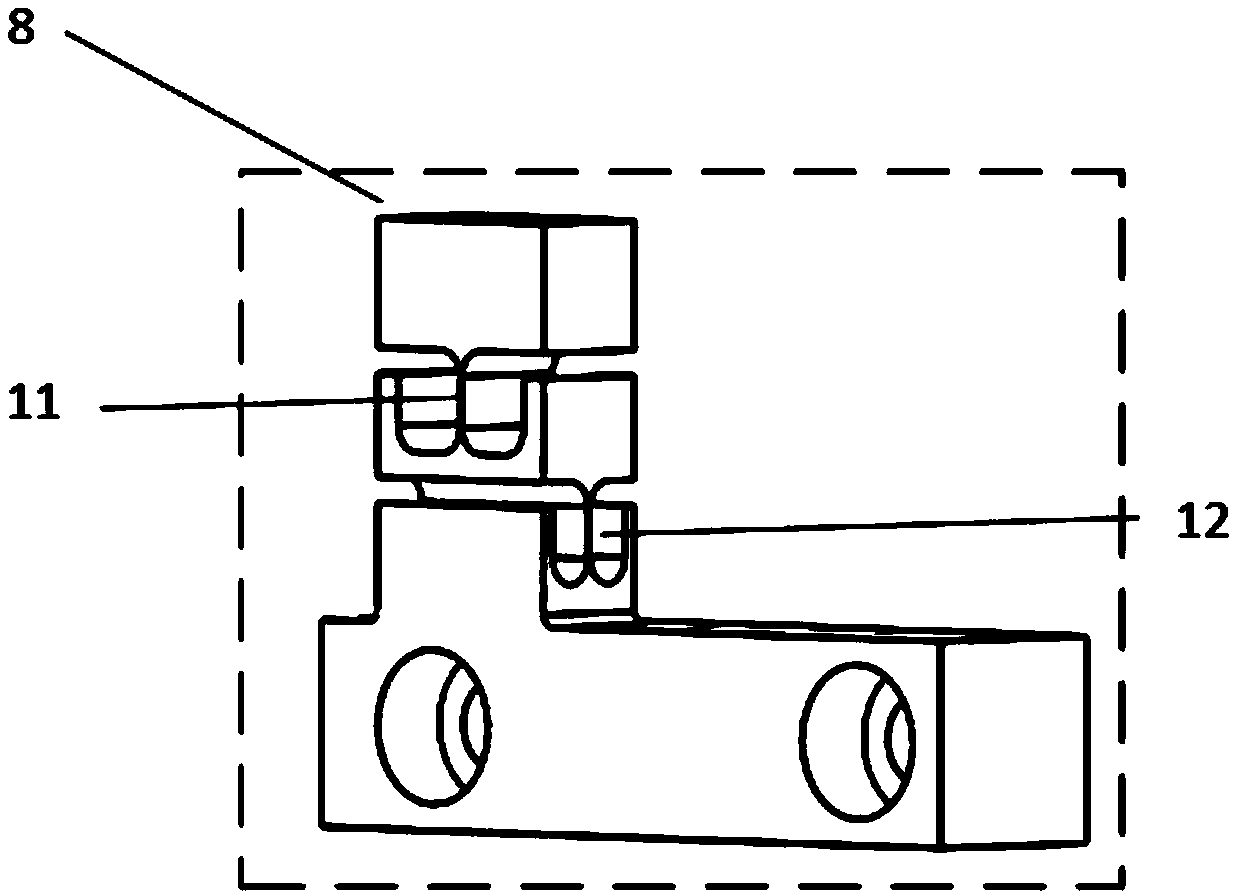

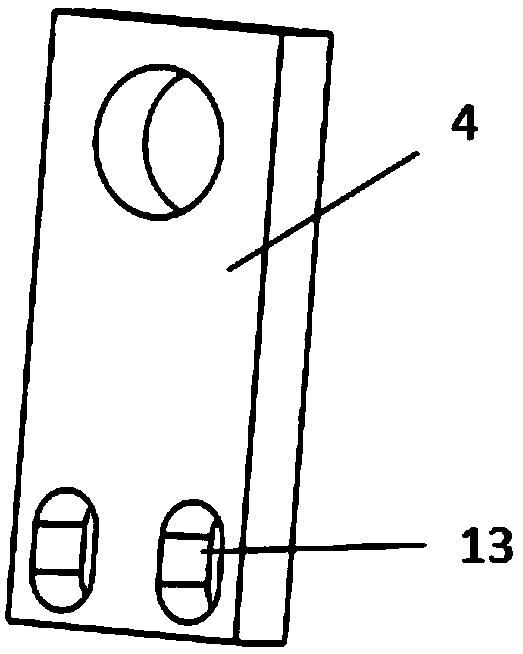

[0018] refer to figure 1 , 2 , a parallel motion mechanism adjustment device based on a biaxial flexible hinge, including a driven linear motion part 5 and a driven guide mechanism 6, the driven linear motion part 5 is movably assembled on the driven guide mechanism 6, and the driven The linear motion part 9 is movably assembled on the active guide mechanism 10, and the two-dimensional adjustment module 8 is fixed on the active linear motion part 9 through the fixing screw 7; Two mounting screws 1 are mated respectively in the two long holes 13, and the connecting seat plate 4 is assembled on the two-dimensional adjustment module 8 through the two mounting screws 1, and the connecting seat plate 4 is adjusted through the upper adjusting positioning nut 2 and the lower adjusting positioning nut. 3 is clamped and positioned to be connected with the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com