Flexible cover plate of display panel

A display panel and flexible cover technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve problems such as black spots, poor water resistance, and glass display cover that cannot be bent, so as to ensure water resistance and good bending The effect of foldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

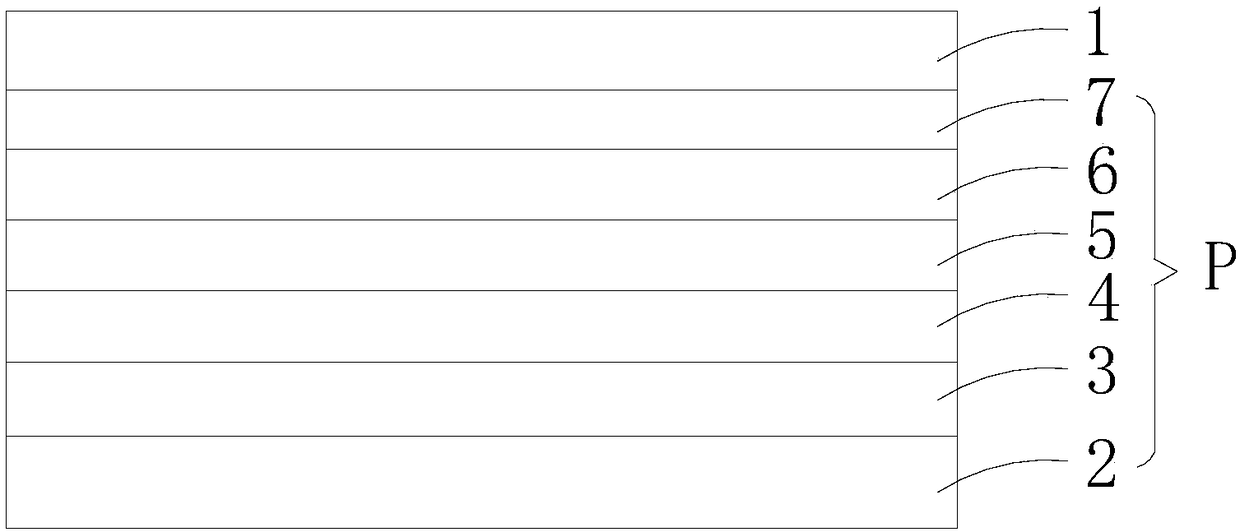

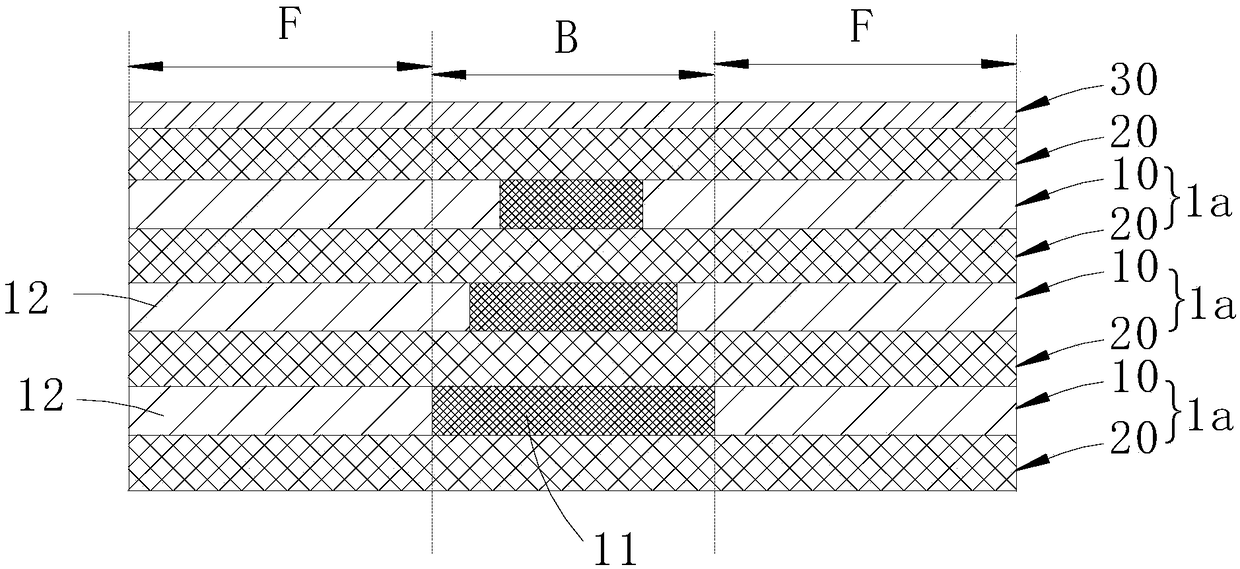

[0034] combine figure 2 As shown, the flexible cover plate 1 of this embodiment includes at least one layer of laminated units 1a, and each layer of laminated units 1a includes a layer of composite layer 10 and a bendable organic layer 20 disposed at the bottom of the composite layer 10, and covers the The transparent hardened layer 30 on the top of the flexible cover plate 1 (that is, its light-emitting surface), the hardened layer can be a transparent inorganic material, such as an inorganic material including Siloxane (siloxane), which can be used in an unusually wide temperature range (- (100℃~250C) can maintain its physical properties, forming a protective material with high temperature resistance, oxidation resistance, good stability, and good water repellency and dielectric properties. Each composite layer 10 has substantially the same composition, including a first part 11 in the middle and second parts 12 located at both ends of the first part 11 . The first part 11...

Embodiment 2

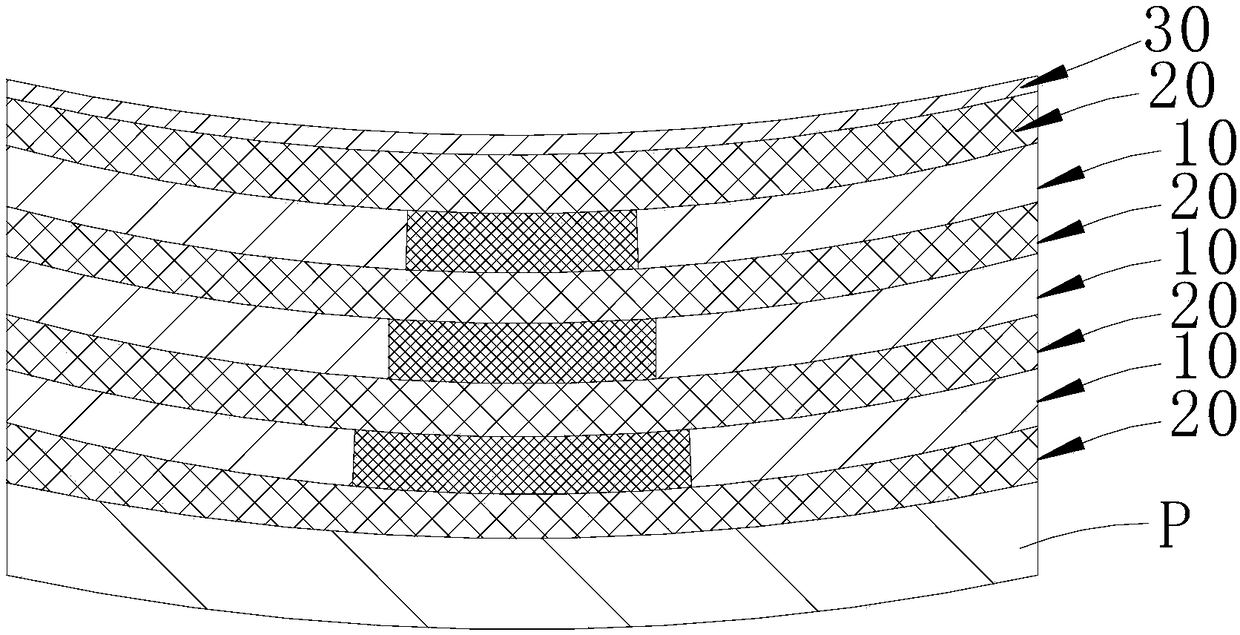

[0043] combine Figure 4 and Figure 5 As shown, the difference from Embodiment 1 is that the flexible cover 1 of this embodiment arches away from the OLED panel P to form a convex display surface, and the hardened layer 30 on the side where the light-emitting surface is located has a convex curved surface structure. The middle area of the hardened layer 30 is a bent portion facing the first portion 11 of each composite layer 10 , and the edge area of the hardened layer 30 is a flat portion connected to the bent portion.

[0044] In this kind of curved flexible cover 1, the farther away from the OLED panel P, the greater the tensile stress on the flexible cover 1, especially in the middle area of the flexible cover 1. Therefore, in this embodiment, the closer to the hardened layer 30. The greater the width of the first part 11 of each composite layer 10, the greater the stress on the bendable region B during bending can be reduced, and the second part of each composite ...

Embodiment 3

[0048] Such as Figure 6-8 As shown, different from the above embodiments, the flexible cover 1 of this embodiment can be bent multiple times, including a plurality of non-bending regions F and a bendable region between every two non-bending regions F B. Correspondingly, each layer of composite layer 10 includes a plurality of second parts 12 and a first part 11 connected between every two second parts 12, and the hardened layer 30 includes a plurality of first parts connected to each composite layer 10. The bending part facing the part 11.

[0049] This embodiment shows the situation that the flexible cover 1 has two bendable regions B, and the bending directions of the two bendable regions B are opposite to facilitate proper folding and unfolding of the display device. Correspondingly, the hardened layer 30 has two bent portions facing the first part 11 of each composite layer 10 respectively, and one of the bendable regions B of the flexible cover plate 1 is bent in the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com