Electric pressure cooker and rapid air exhaust control method

A technology of electric pressure cooker and control method, applied in pressure cooker, overflow prevention, cooking utensils, etc., can solve the problems of up to 40-60min, overflow of exhaust port, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

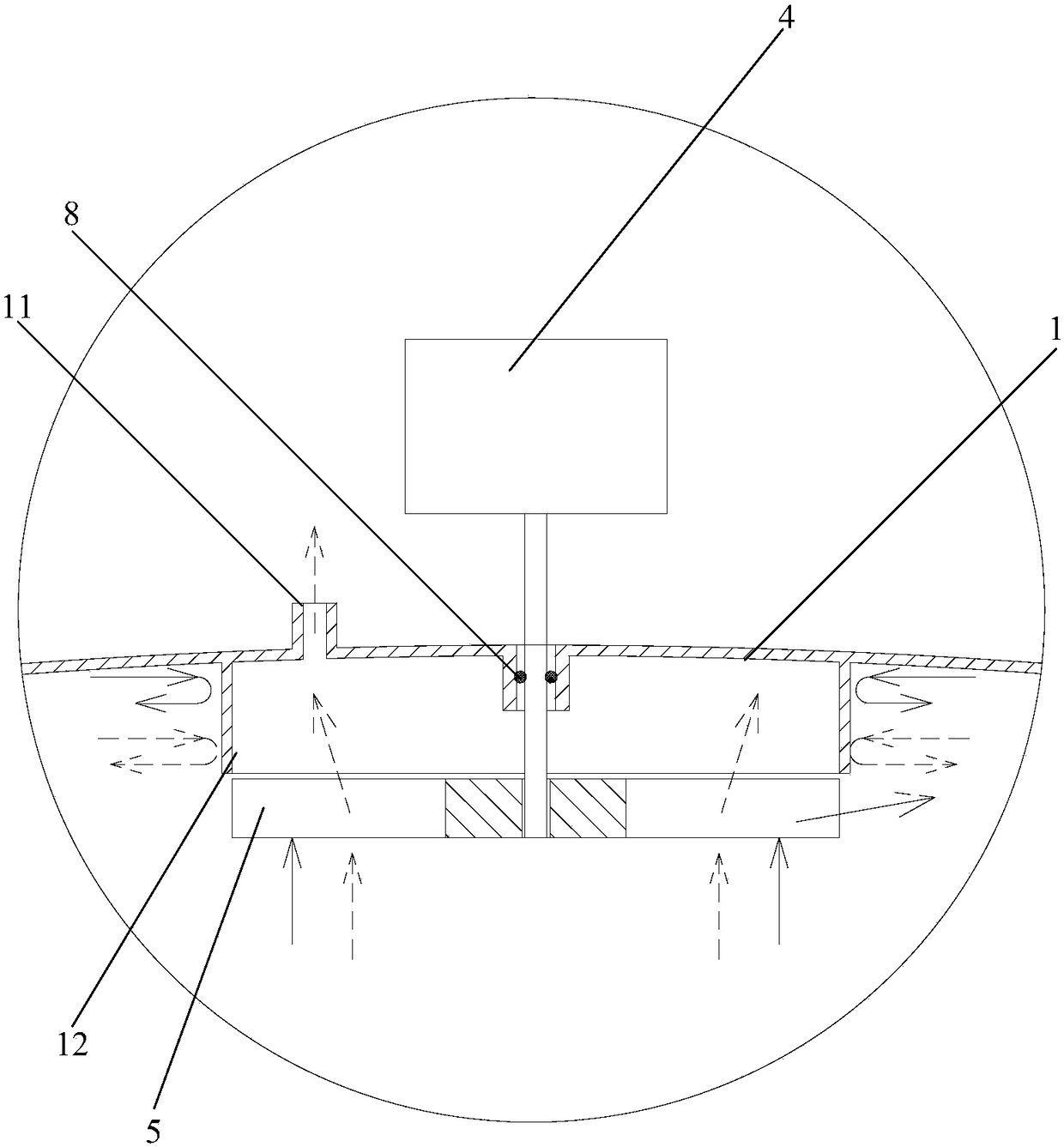

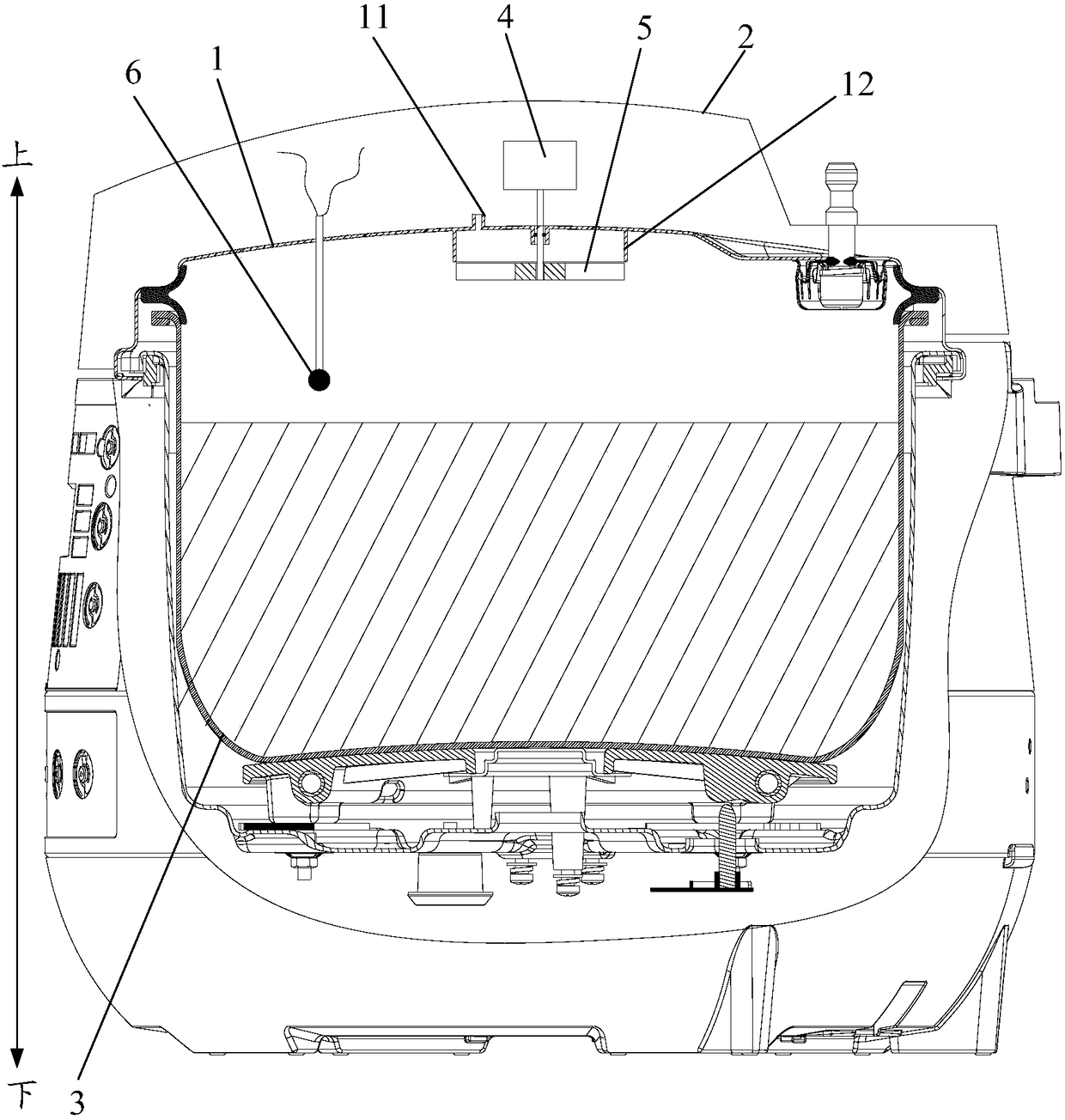

[0064] Such as figure 1 with figure 2 As shown, the electric pressure cooker provided by this solution has a pot cover and a pot body, wherein the pot cover includes an outer cover 2 and an inner cover 1 installed at the bottom of the outer cover 2, and the inner cover 1 is provided with an exhaust port 11 and a mounting hole, and the impeller 5 is located below the exhaust port 11 of the inner cover 1, the motor 4 is installed above the inner cover 1, the shaft of the motor 4 passes through the mounting hole and is connected to the impeller 5, and the pot body includes an inner pot 3 for holding food. The electric pressure cooker also includes a controller and a pressure sensor 6. The pressure sensor 6 is installed on the pot cover and electrically connected to the controller. When the pot cover is closed with the pot body, the detection probe of the pressure sensor 6 is directly inserted into the inner pot 3 to detect the cooking cavity. and transmit the pressure detection...

Embodiment 2

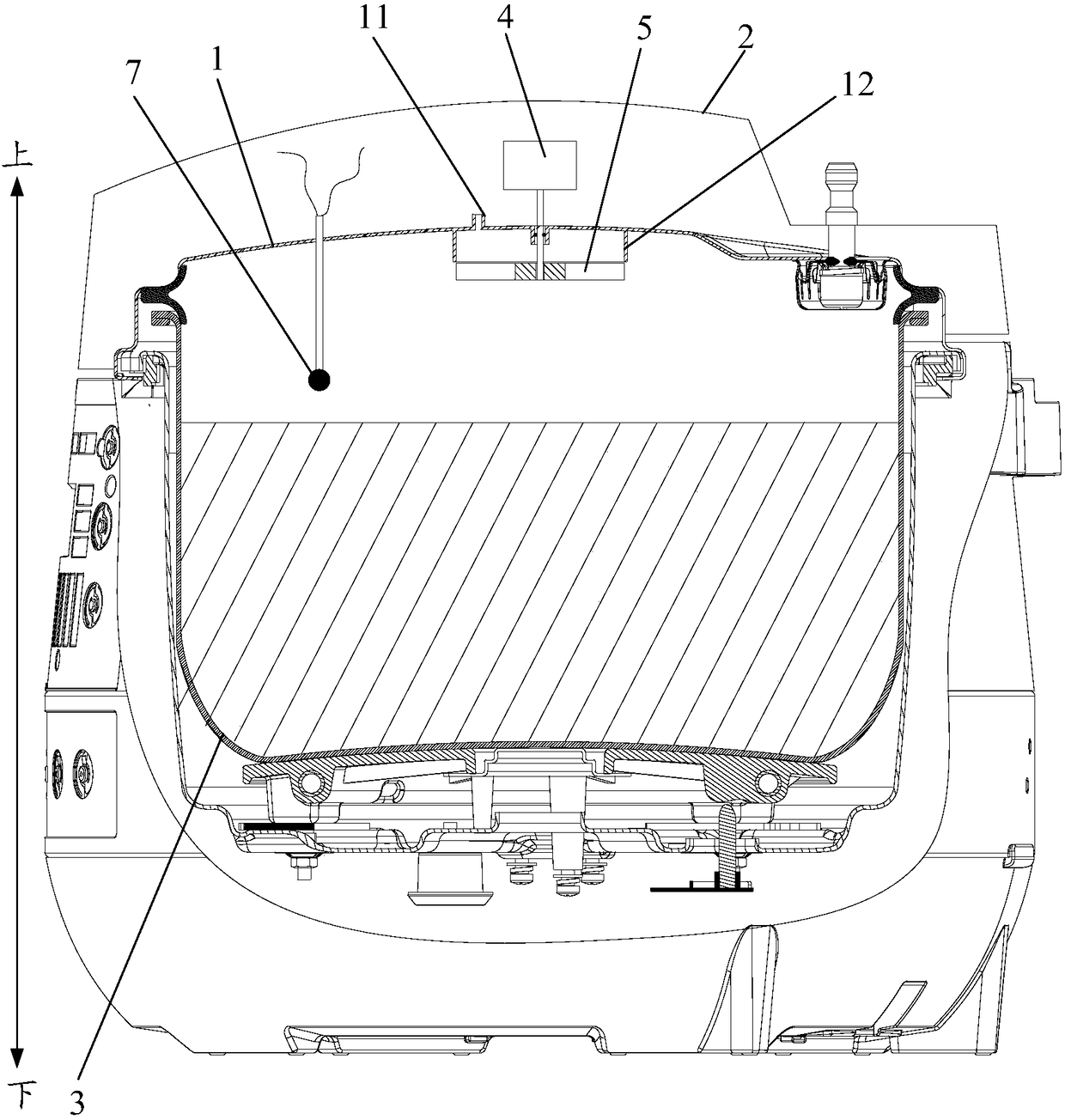

[0067] Such as figure 1 with image 3 As shown, the electric pressure cooker provided by this solution has a pot cover and a pot body, wherein the pot cover includes an outer cover 2 and an inner cover 1 installed at the bottom of the outer cover 2, and the inner cover 1 is provided with an exhaust port 11 and a mounting hole, and the impeller 5 is located below the exhaust port 11 of the inner cover 1, the motor 4 is installed above the inner cover 1, the shaft of the motor 4 passes through the mounting hole and is connected to the impeller 5, and the pot body includes an inner pot 3 for holding food. The electric pressure cooker also includes a controller and a temperature sensor 7. The temperature sensor 7 is installed on the pot cover and is electrically connected to the controller. When the pot cover is closed with the pot body, the detection probe of the temperature sensor 7 extends into the inner pot 3 for detecting The temperature of the steam in the cooking cavity, a...

Embodiment 3

[0072] Such as figure 1 with Figure 4 As shown, the electric pressure cooker provided by this solution has a pot cover and a pot body, wherein the pot cover includes an outer cover 2 and an inner cover 1 installed at the bottom of the outer cover 2, and the inner cover 1 is provided with an exhaust port 11 and a mounting hole, and the impeller 5 is located below the exhaust port 11 of the inner cover 1, the motor 4 is installed above the inner cover 1, the shaft of the motor 4 passes through the mounting hole and is connected to the impeller 5, and the pot body includes an inner pot 3 for holding food. The electric pressure cooker also includes a controller and a temperature sensor 7, the temperature sensor 7 is installed at the bottom of the inner pot 3 and is electrically connected to the controller, for detecting the temperature at the bottom of the inner pot 3, and sending the temperature detection signal at the bottom of the pot to the controller, The controller calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com