Aerogel composite glass preparation method

A technology of composite glass and aerogel, which is applied in the field of preparation of aerogel composite glass, can solve the problems of difficult mixing of aerogel and glass melt, and achieve the effects of eliminating delamination, excellent characteristics and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

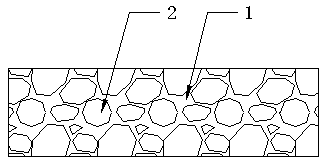

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

[0026] Embodiments of the present invention are as follows, a method for preparing an airgel composite glass, comprising the following steps:

[0027] (1) Mix the glass powder and airgel evenly;

[0028] (2) Lay a layer of mixture on the mold substrate first;

[0029] (3) Use a laser to quickly heat the obtained mixture in a step-by-step scanning manner until the glass powder in it melts and the airgel does not melt;

[0030] (4) Repeat steps (2) and (3) alternately on the previous deposition layer, and cool to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com