An environmentally friendly permeable brick made of recycled materials from construction waste

A technology for construction waste and seepage bricks, applied in the field of seepage bricks, can solve problems such as urban waterlogging, difficult evaporation of groundwater, and damage to the urban water cycle process, and achieve the effect of improving waterlogging and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

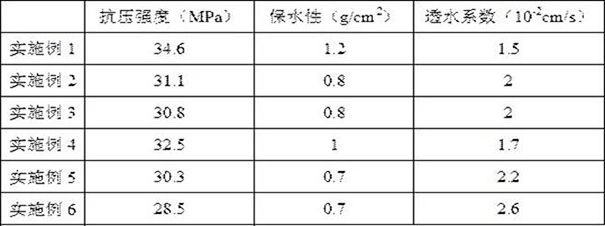

Examples

Embodiment 1

[0020] An environmentally friendly permeable brick prepared from recycled materials from construction waste. The mass components of the permeable base are: 40 parts of recycled fine aggregate, 30 parts of recycled sand, 5 parts of fly ash, 15 parts of cement, and 0.5 parts of water reducer , 13 parts of water; the mass components of the permeable surface layer are: 70 parts of reclaimed sand, 20 parts of cement, 7 parts of fly ash, 2 parts of mineral pigment, 0.5 part of water-permeable agent, 0.8 part of water-reducing agent, and 17 parts of water.

[0021] Its preparation process is as follows:

[0022] (1) Prepare cementitious base material and wet base material: Stir cement and water reducer evenly, add fly ash to mix to prepare cementitious base material; mix recycled fine aggregate and recycled sand evenly, add 3~ 5 parts water, mixed to make a wet base material;

[0023] (2) Prepare the concrete base material: mix the gel base material and the wet base material in step...

Embodiment 2

[0029] An environmentally friendly permeable brick prepared from recycled materials from construction waste, its preparation method is basically the same as in Example 1, the difference is that the mass components of the permeable base used are: 50 parts of recycled fine aggregate, 30 parts of regenerated sand, fly ash 3 parts, 10 parts of cement, 0.5 parts of water reducing agent, 15 parts of water; the mass components of the permeable surface layer are: 65 parts of reclaimed sand, 15 parts of cement, 5 parts of fly ash, 1.5 parts of mineral pigment, and 0.3 parts of water permeable agent , 0.8 parts of water reducer, 10 parts of water.

Embodiment 3

[0031] An environmentally friendly permeable brick prepared from recycled materials from construction waste, its preparation method is basically the same as in Example 1, the difference is that the mass components of the permeable base used are: 60 parts of recycled fine aggregate, 30 parts of regenerated sand, fly ash 8 parts, 20 parts of cement, 0.8 parts of water reducing agent, 15 parts of water; the mass components of the permeable surface layer are: 70 parts of reclaimed sand, 30 parts of cement, 10 parts of fly ash, 3 parts of mineral pigment, 0.5 parts of water permeable agent , 1 part of water reducer, 20 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com