Acrylonitrile-butadiene-styrene composition for realizing spray coating flowing mark avoidance and preparation method thereof

A technology of acrylonitrile and butadiene, which is applied in the field of acrylonitrile-butadiene-styrene composition and its preparation, can solve the problems of product appearance quality discount, not being effectively solved, flow marks and other problems, and achieve the elimination of appearance Defects, considerable benefits, the effect of smooth flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Mix 82 parts of Chimei's PA-709, 2 parts of light stabilizer, 2 parts of heat stabilizer, 10 parts of chemical treatment agent, 2 parts of processing aid, and 2 parts of aluminum silver powder through high-speed stirring, and send the above mixture into the twin-screw In the extruder, it is fully melted and compounded under the conveying and shearing action of the screw, and then extruded through the head die, drawn, cooled and pelletized.

[0043] The temperature of the first zone of the twin-screw extruder is controlled at 200°C, the temperature of the screws from the second zone to the head of each section is controlled between 220 and 260°C, and the screw speed is 350r / min.

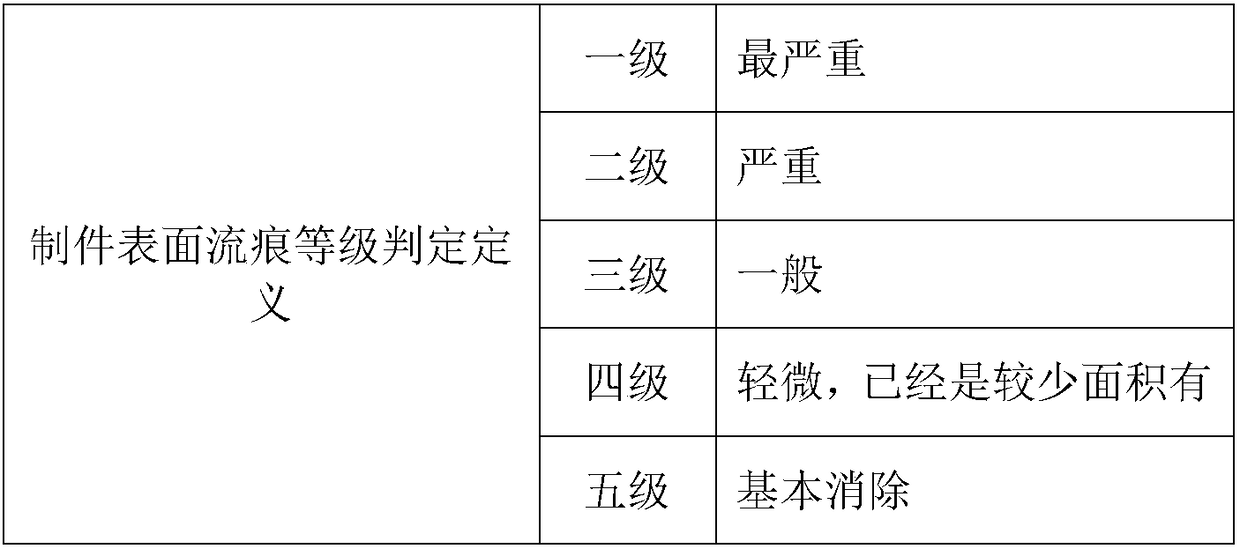

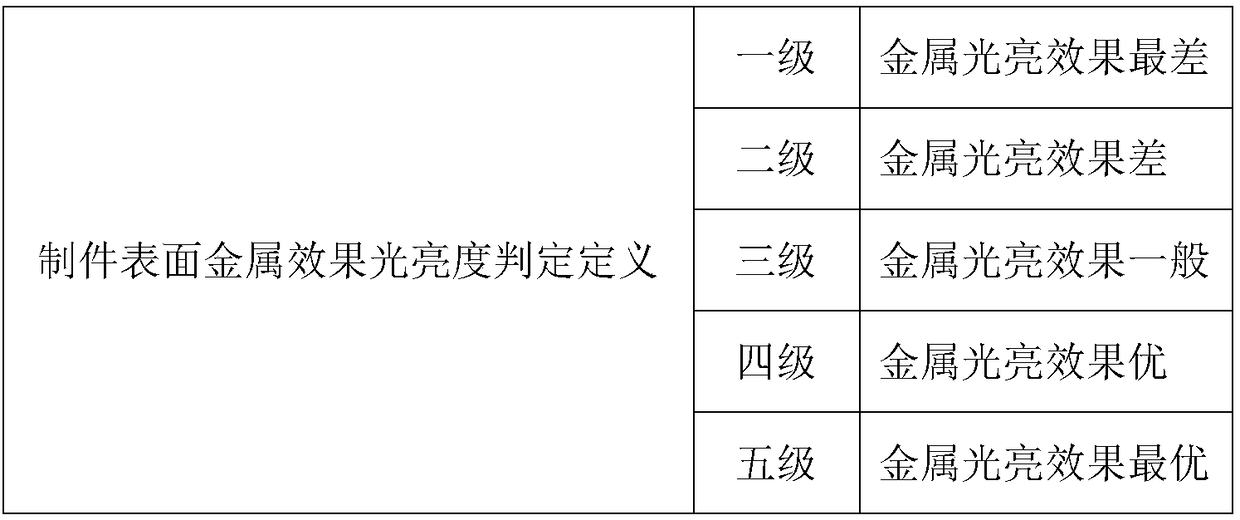

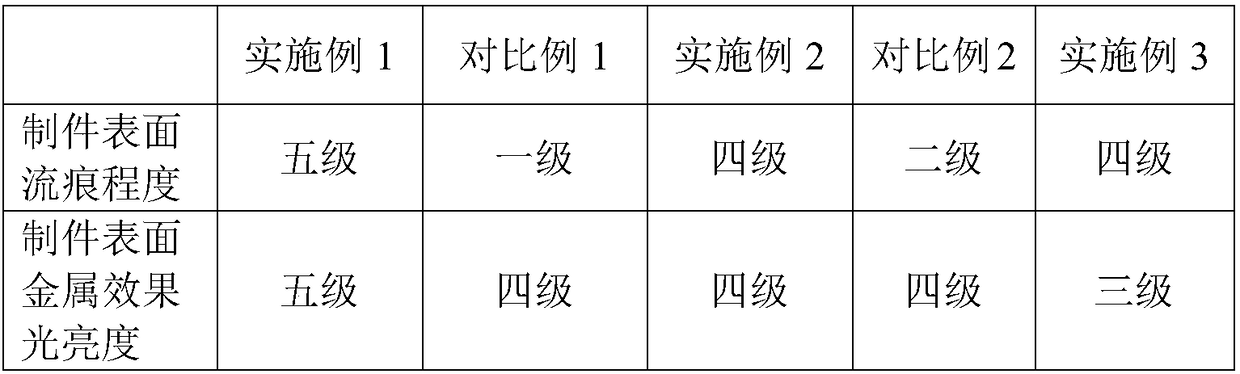

[0044] Injection molded into a test sample part, the degree of flow marks on the surface of the part and the brightness of the metal effect on the surface of the part were tested. The results are shown in Table 3.

Embodiment 2

[0050] Mix 90 parts of Chimei's PA-709, 1 part of light stabilizer, 1 part of heat stabilizer, 6 parts of chemical treatment agent, 1 part of processing aid, and 1 part of aluminum silver powder through high-speed stirring, and send the above mixture into the twin-screw In the extruder, it is fully melted and compounded under the conveying and shearing action of the screw, and then extruded through the head die, drawn, cooled and pelletized.

[0051] The temperature of the first zone of the twin-screw extruder is controlled at 200°C, the temperature of the screws from the second zone to the head of each section is controlled between 220 and 260°C, and the screw speed is 350r / min.

[0052] Injection molded into a test sample part, the degree of flow marks on the surface of the part and the brightness of the metal effect on the surface of the part were tested. The results are shown in Table 3.

Embodiment 3

[0058] Mix 97.25 parts of Chimei's PA-709, 0.5 parts of light stabilizer, 0.1 part of heat stabilizer, 2 parts of chemical treatment agent, 0.1 part of processing aid, and 0.05 parts of aluminum silver powder through high-speed stirring, and send the above mixture into the twin-screw In the extruder, it is fully melted and compounded under the conveying and shearing action of the screw, and then extruded through the head die, drawn, cooled and pelletized.

[0059] The temperature of the first zone of the twin-screw extruder is controlled at 200°C, the temperature of the screws from the second zone to the head of each section is controlled between 220 and 260°C, and the screw speed is 350r / min.

[0060] Injection molded into a test sample part, the degree of flow marks on the surface of the part and the brightness of the metal effect on the surface of the part were tested. The results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com