Point and line engaged worm lifting mechanism

A worm and meshing technology, applied in the field of point-line meshing worm hoisting mechanism, can solve problems such as easy failure of gear teeth, achieve the effect of not easy to break teeth, broaden the scope of application, and enrich the theoretical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

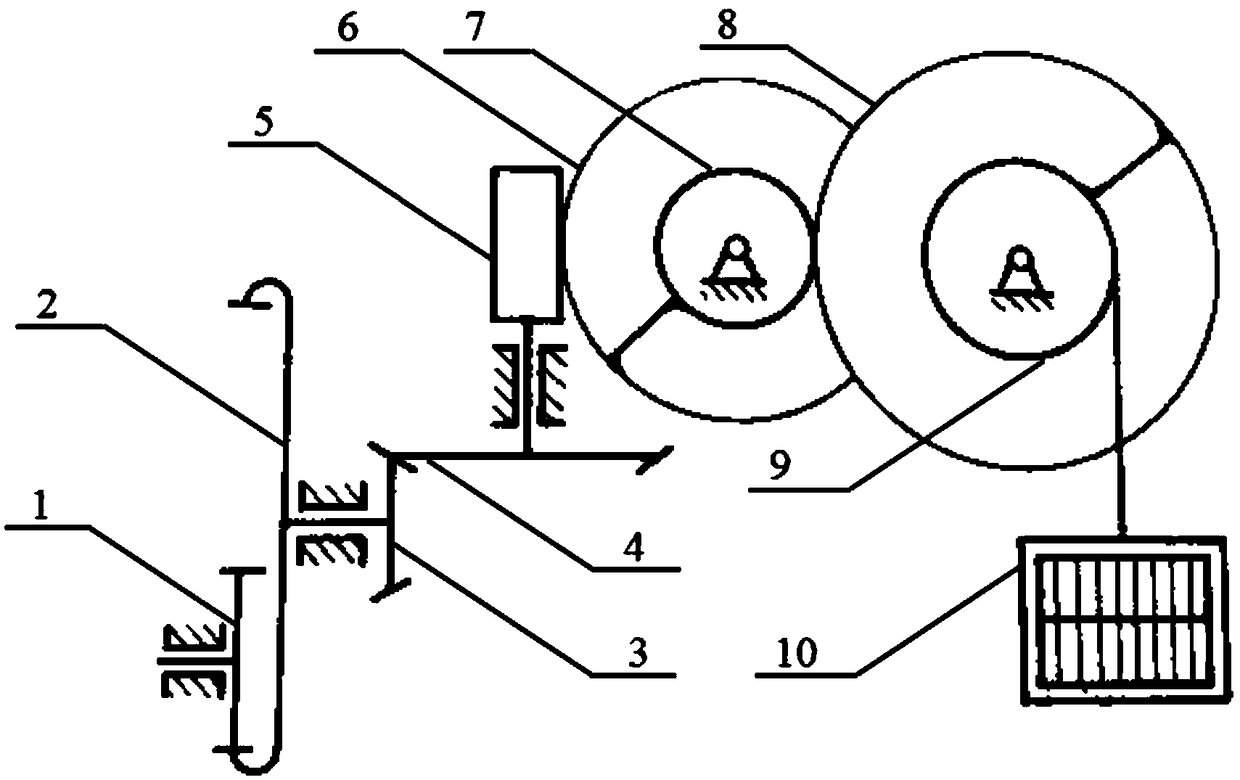

[0020] Such as figure 1 , a point-line meshing worm lifting mechanism, including a first helical gear 1 and a second helical gear 2 meshing with each other, the center of the second helical gear 2 is fixed with a first connecting shaft, and the other end of the first connecting shaft is fixed with a first Bevel gear 3, the first bevel gear 3 is meshed with a second bevel gear 4, the second bevel gear 4 is fixed with a second connecting shaft, the other end of the second connecting shaft is fixed with a worm 5, and the worm 5 is meshed with a transmission wheel 6. The transmission wheel 6 is a worm gear or the third helical gear, the transmission wheel 6 is fixed with a third connecting shaft, the third connecting shaft is fixed with a fourth helical gear 7, and the fourth helical gear 7 is meshed with a fifth helical gear 8 , a drum 9 is fixed on the end face of the fifth helical gear 8, and the rotation axis of the drum 9 coincides with the rotation axis of the fifth helical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com