A method for controlling the welding structure of heavy-duty rail

A control method and rail technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems that the post-weld cooling rate cannot be realized, and the control effect needs to be investigated, so as to improve the uniformity of the structure and enrich the theory The effect of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

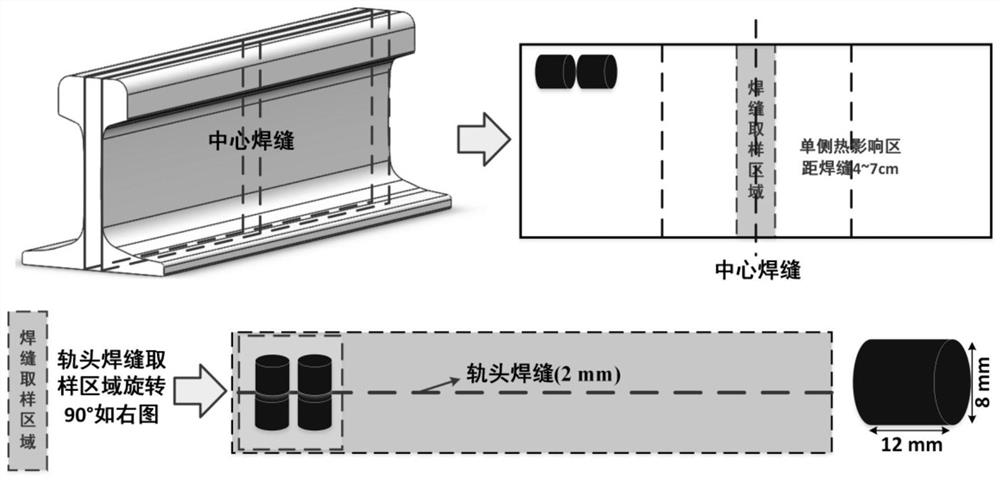

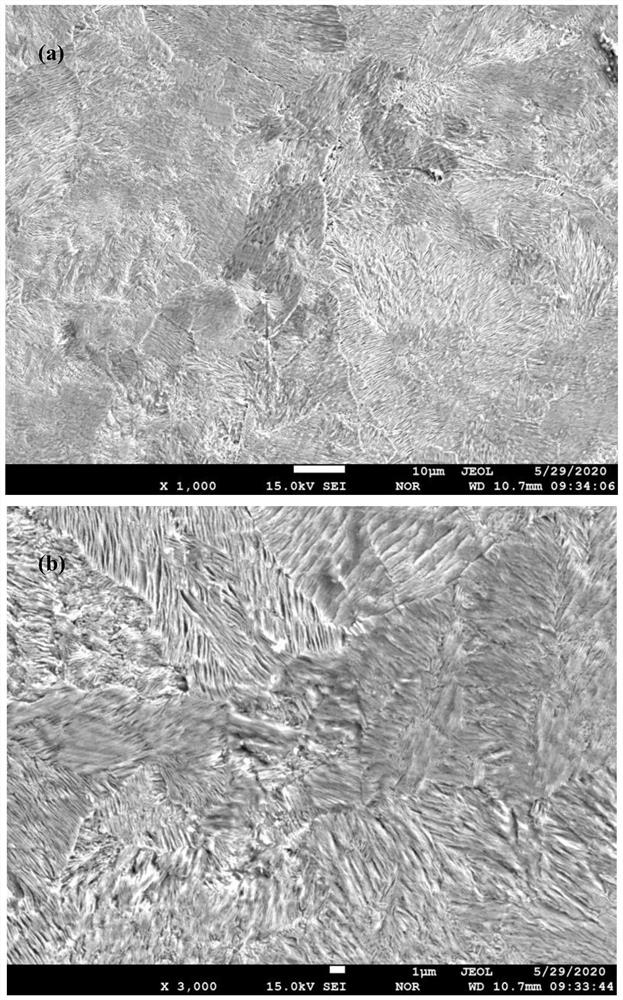

[0043] Research on the formation of abnormal martensitic structure at the weld position of bainite rail welded joints:

[0044] Aiming at the problem of abnormal martensitic structure at the welding seam position of the bainite rail after welding, this example focuses on the influence of the cooling rate on the abnormal martensite structure at the welding seam position of the heavy-duty rail after welding The research is the starting point to determine the optimal post-weld cooling system to suppress the formation of abnormal martensitic structure at the weld position at the welded joint.

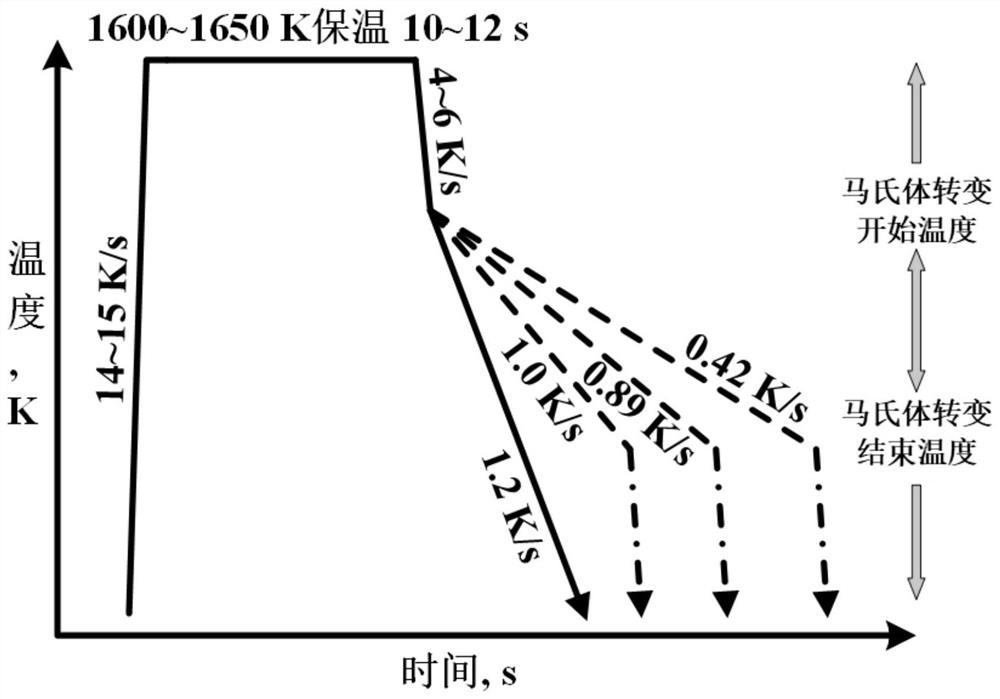

[0045] Firstly, using the deformation thermal expansion phase transition instrument DIL805, the CTT curves of different phase transitions of the heavy-duty steel rails used at different cooling rates were obtained, so as to obtain the martensite transformation start temperature and martensite transformation end temperature under the corresponding element composition, and then According to t...

Embodiment 2

[0066] Research on the formation of abnormal martensitic structure at the welded joints of hypereutectoid heavy-duty rails:

[0067] Use the formula K1=399.8-11.5×(7.37x) V1 With K2=259.5-14.1×(6.76x) V2 , where, x=C Mn / 12+Cr / 35+Ni / 21+Mo / 20+Si / 40-V / 3-Al / 21, V1 is the cooling of the martensitic transformation start temperature K1 after welding Rate (K / s), V1 is 3-5K / s, in calculation, V1=4K / s, V2 is the cooling rate (K / s) that martensite transformation start temperature K1 cools to martensite transformation end temperature K2 ), V2=0.3K / s; calculated, the martensite transformation start temperature K1 is 611.54K, and the martensite transformation end temperature K2 is 520.86K.

[0068] After welding the eutectoid heavy-duty rail joint, during the cooling process of the welded joint, control the cooling process of the weld position at the welded joint; specifically, the following steps are included:

[0069] Step 1: According to the calculated martensite transformation start ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com