A spreader for upright hoisting of circular sheet metal and its application method

A circular plate and spreader technology, applied in the manufacturing field, can solve the problems of easily damaged plate surface, complicated operation, low safety, etc., and achieve the effect of avoiding crack source, simple operation and high lifting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

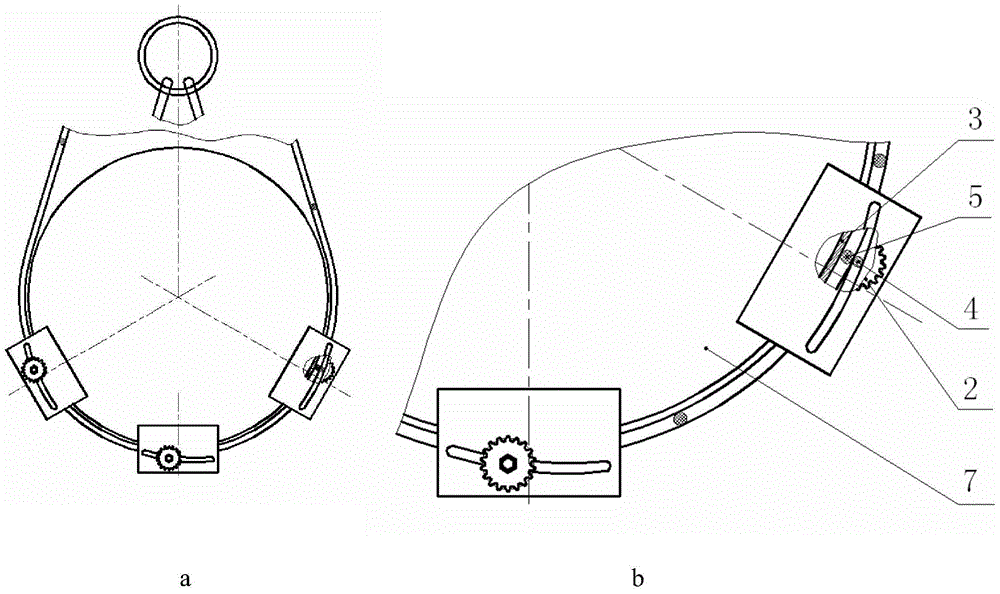

[0040] This embodiment is a sling used for upright lifting of circular panels, the diameter of the lifted circular panels is between 1000mm and the weight is 120Kg.

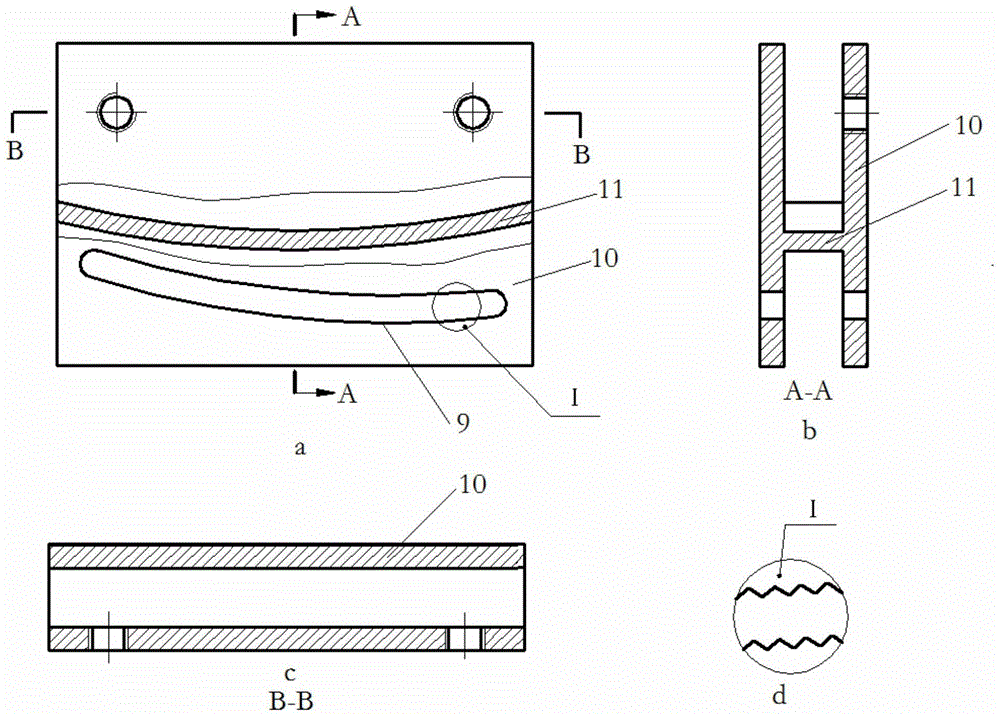

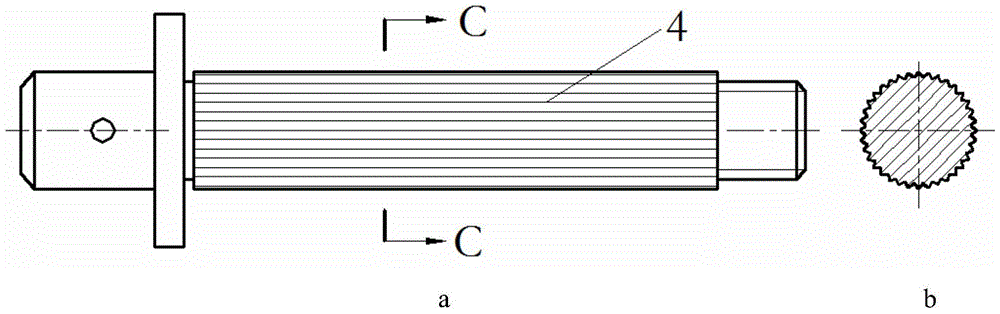

[0041] This embodiment includes a clamping plate 3 , a straight knurled shaft 4 , a lock nut 6 and an embossed handle 2 . Wherein, the outer shape of the clamping board is "H" shape, and the distance between the vertical plates 10 on both sides of the "H"-shaped clamping board is used to place the sheet material. The horizontal plate 11 forming the middle part of the "H" shaped clamping plate is an arc plate; the length of the horizontal plate is the same as the width of the vertical plates on both sides of the clamping plate. The lower part of the vertical plate on both sides of the clamping plate 3 is provided with an arc-shaped knurled shaft groove 9 in the same direction as the horizontal plate; Shaft groove engagement. There is the mounting hole of micro-adjustment screw 8 on the top of the vertical plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com