Preparation method of reinforced copper-based strip

A copper-based, enhanced technology, applied in the direction of manufacturing tools, furnace types, metal rolling, etc., can solve the problems of not being able to have both high strength and high conductivity, and achieve good matching, quality improvement, and uniform texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 The preparation method of reinforced copper-based strip material X1

[0026] Pretreatment: Use pure copper foil as the base material with a purity of 99.9% and a thickness of 50 microns; place the copper foil in pickling solution (mixed with acetic acid and water at a volume ratio of 1:1) and ultrasonically treat it for 10 minutes. After cleaning with deionized water, put it into ethanol for ultrasonic treatment for 10 minutes, dry it before use, and store it in acetone when it is not used for a long time.

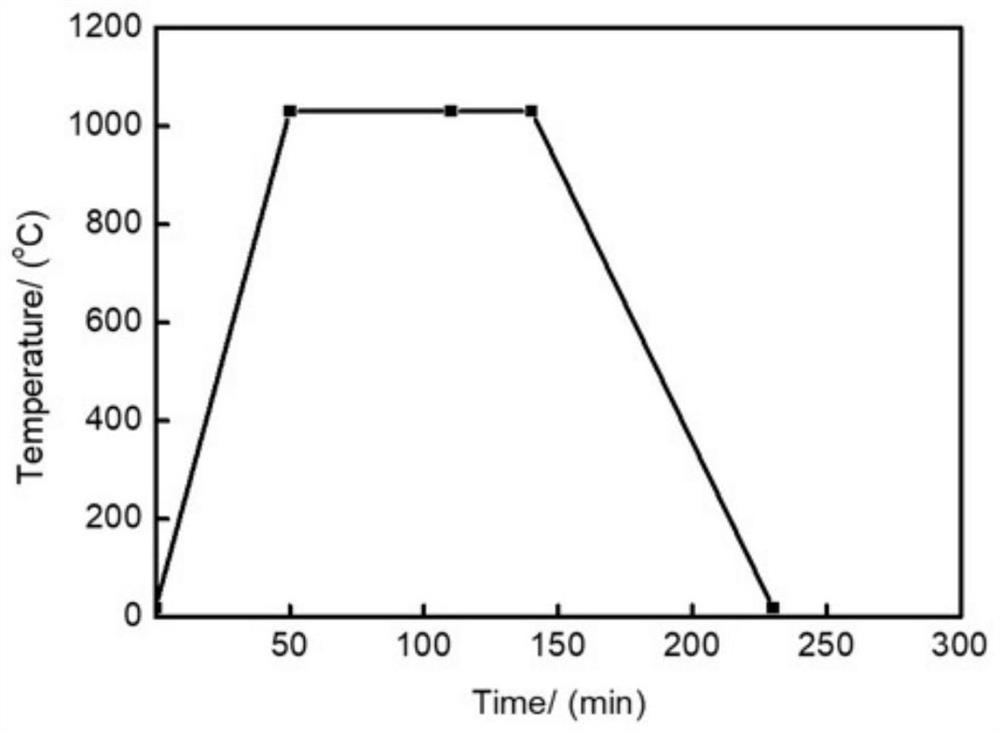

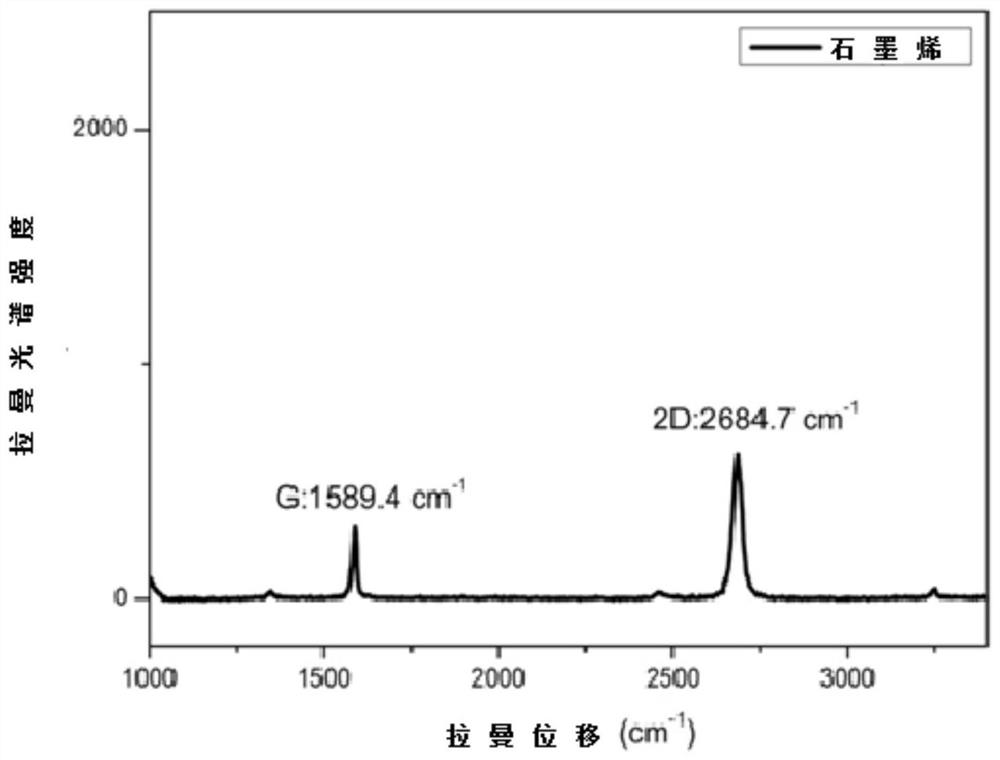

[0027] In-situ growth: the copper foil is processed into a cylindrical shape by folding and placed in a CVD furnace tube, and methane is used as a carbon source to perform roll-to-roll continuous graphene in-situ growth on the surface of the copper foil. The specific process is: put the sample into the CVD furnace at room temperature, close the furnace tube; use the vacuum pump to continuously pump out the residual air in the furnace, then turn off the ...

Embodiment 2

[0031] Embodiment 2 The preparation method of reinforced copper-based strip material X2

[0032] Pretreatment: Use copper-nickel alloy foil with a copper content of 78% as the substrate, with a thickness of 100 microns; place the copper-nickel foil in pickling solution (mixed with acetic acid and water at a volume ratio of 1:1) and ultrasonically treat it for 15 minutes , washed with deionized water, then placed in ethanol for ultrasonic treatment for 15 minutes, dried for later use, and stored in acetone for long-term use.

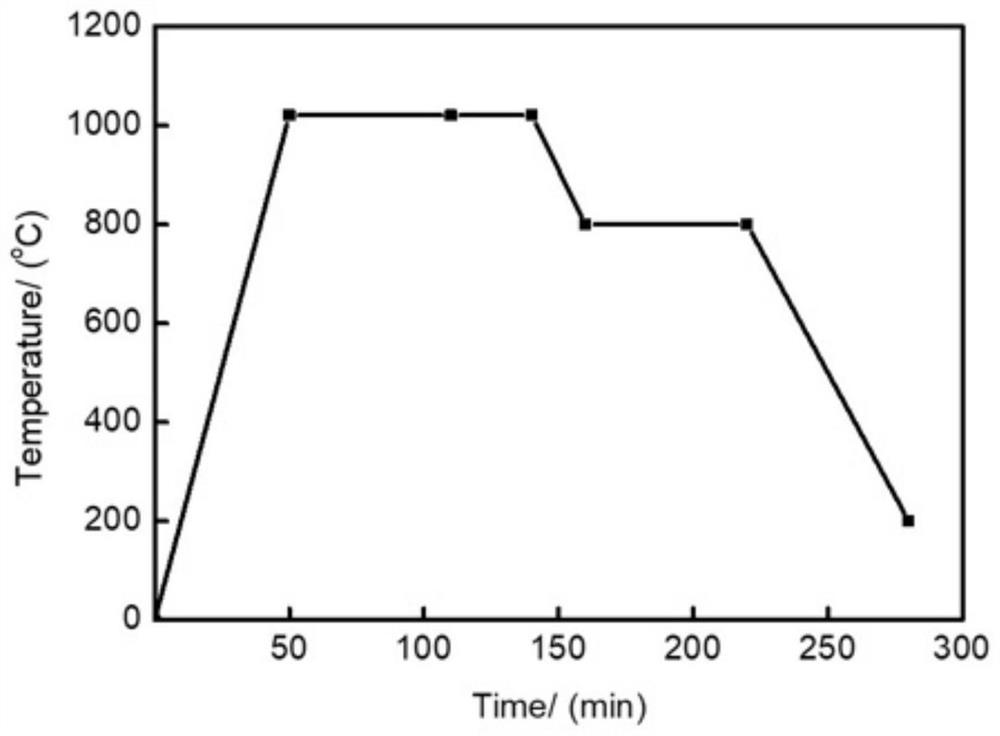

[0033] In-situ growth: Copper-nickel foil is processed into a cylindrical shape by curling and placed in a CVD furnace tube, and acetylene is used as a carbon source to perform in-situ growth of roll-to-roll continuous graphene on the surface of the copper alloy foil. The specific process is: close the CVD furnace tube; use the vacuum pump to continuously pump out the residual air in the furnace, then close the vacuum pump and feed the gas, in which the a...

Embodiment 3

[0037] Embodiment 3 The preparation method of reinforced copper-based strip material X3

[0038] Pretreatment: Use copper-nickel alloy foil with a copper content of 57% as the substrate, with a thickness of 75 microns; place the copper-nickel foil in pickling solution (mixed with acetic acid and water at a volume ratio of 1:1) and ultrasonically treat it for 5 minutes , washed with deionized water, then placed in ethanol for ultrasonic treatment for 5 minutes, dried for later use, and stored in acetone for long-term use.

[0039] In-situ growth: The copper-nickel foil is processed into a cylindrical shape by curling and placed in a CVD furnace tube, and ethanol is used as the carbon source to perform in-situ growth of roll-to-roll continuous graphene on the surface of the copper alloy foil. The specific process is as follows: close the CVD furnace tube; use the vacuum pump to continuously pump out the residual air in the furnace, then close the vacuum pump and introduce gas, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com