A channel blasting method for thick and large ore bodies

A technology of thick and large ore bodies and slotting, which is applied in blasting and other directions, can solve the problems of high cost, long period, and low efficiency of slotting, and achieve the effect of low cost, short cycle and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0023] Thick and large ore body slotting blasting method of the present invention, the method comprises the following steps:

[0024] (1) Blast hole design and construction:

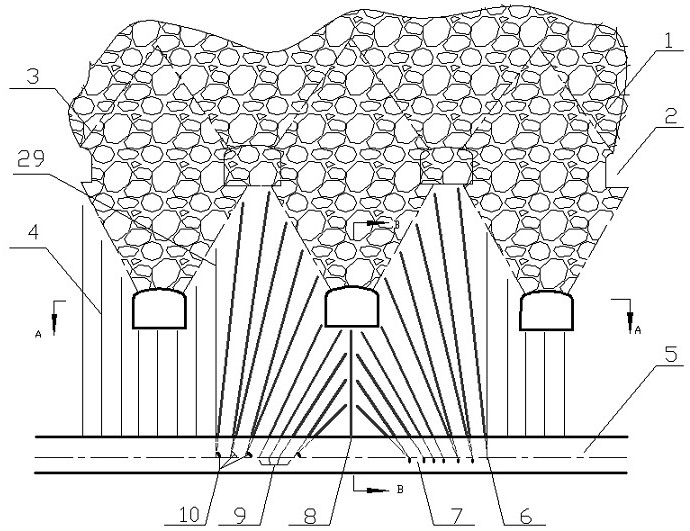

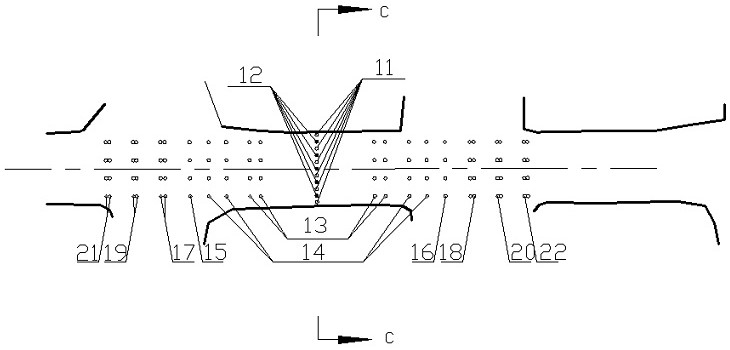

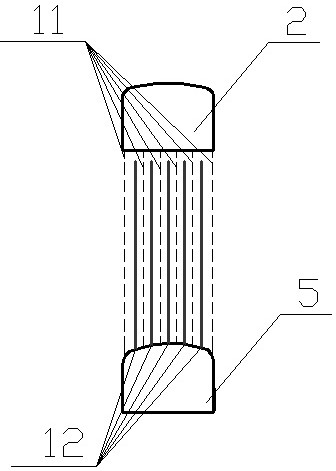

[0025] With a layer height of 15m and an approach distance of 20m, the deepest slotted hole in the ore body is two layered heights, the width of the slotted layer connection road is 5.5m, and the roadway height is 4.1m. -100 type rock drilling machine falling parameters as an example.

[0026] According to the positions of the cover layer 1 in the mined-out area and the decommissioned layered route 2, the crack hole 8 is selected directly below the decommissioned layered route, and the cracks and grooves formed after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com