Lifting machine main guide wheel rope groove diameter difference measuring device

A measuring device and hoist technology, applied in the direction of mechanical diameter measurement, etc., can solve the problem of inability to accurately measure the diameter difference of the rope groove, and achieve the effect of ensuring the healthy operation of the equipment, easy operation and improving the measurement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

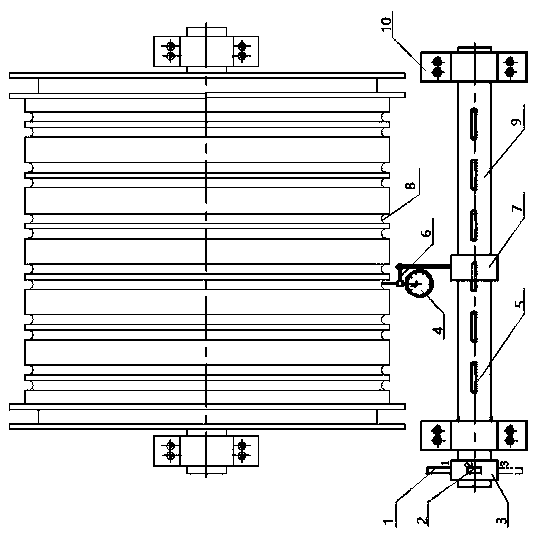

[0017] Such as figure 1 As shown, a hoist capstan pulley rope groove diameter difference measuring device includes a dial indicator 4, a shaft 9, a bearing seat 10, and a supporting mechanism. The two ends of the shaft 9 are supported by the bearing seat 10, and one end of the shaft 9 is also provided with a The mechanism that makes the shaft rotate, the mechanism that can make the shaft rotate includes the first handle 1, the second handle 2, the handle cover 3, the handle cover 3 is sleeved on one end of the shaft 9, and the handle cover 3 is provided with the first handle 1 and the second handle 2. A support mechanism is installed on the shaft 9. The support mechanism includes a connecting rod 6 and a shaft sleeve 7. The shaft sleeve 7 is installed on the shaft 9 through the round key 5. The shaft sleeve 7 and the shaft 9 can slide relatively. Connecting rod 6 is set, and dial indicator 4 is fixedly installed at the end of connecting rod 6, and the measuring head of dial in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com