High pressure gas source-to-work piece inflating method, inflating device and differential pressure airtightness detector

A high-pressure gas source and inflatable device technology, which is used in liquid/vacuum measurement for liquid tightness, gas/liquid distribution and storage, and measurement of fluid acceleration and deceleration rates. The problem of high valve accuracy requirements, to achieve the effect of low production cost, reduce production cost, and realize air pressure control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

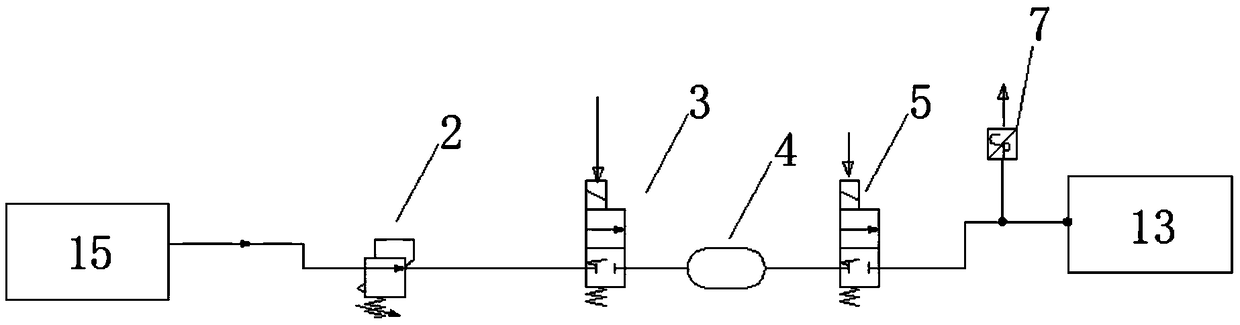

[0031] combined with figure 1 Shown, a kind of inflation method to workpiece by high-pressure gas source, it comprises the following steps:

[0032] (1) A first valve 3, an air tank 4 and a second valve 5 connected in sequence are arranged between the high-pressure gas source 15 and the workpiece 13;

[0033] (2) The first valve 3 is turned on, the second valve 5 is disconnected, and the high-pressure gas source 15 inflates the gas tank 4;

[0034] (3) The first valve 3 is disconnected, the second valve 5 is turned on, and the gas tank 4 inflates the workpiece 13;

[0035] (4) Steps (2) and (3) are repeated, and the first valve 3 and the second valve 5 are alternately turned on and off, so that the high-pressure gas source 15 inflates the workpiece 13 through the gas tank 4 to reach the preset air pressure.

[0036] In the step (2), a fine pressure regulating valve 2 is provided between the first valve 3 and the high-pressure gas source 15 , and the air pressure of the infla...

Embodiment 2

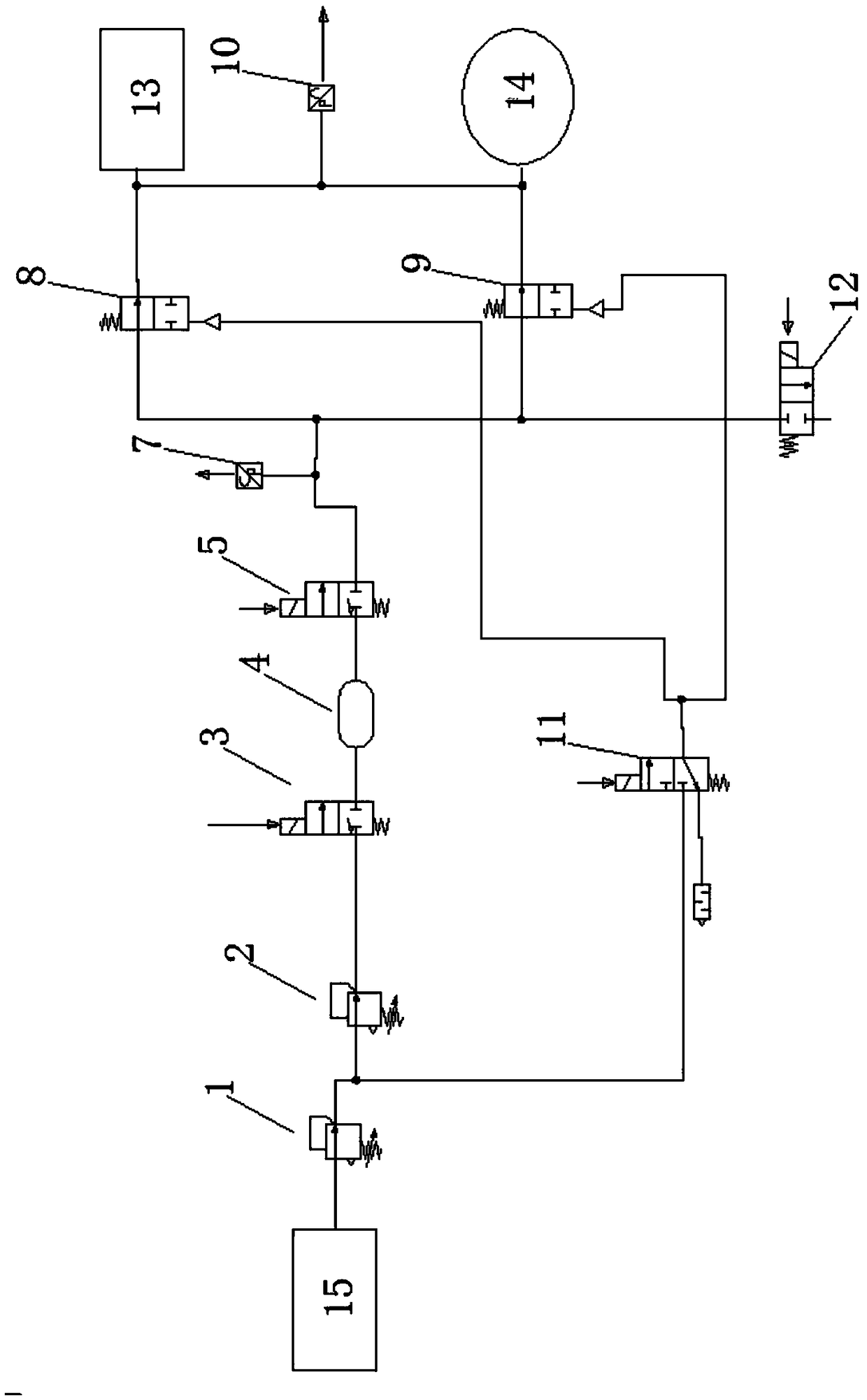

[0039] combined with figure 2 As shown, a differential pressure air tightness detector related to the present invention includes a high pressure gas source 15, a coarse pressure regulating valve 1, a fine pressure regulating valve 2, a buffer device, a pressure sensor 7, a first control valve 8, a second control valve valve 9 and differential pressure gauge 10. The buffer device further includes an air tank 4, and a first electromagnetic valve 3 and a second electromagnetic valve 5 arranged at the air inlet and exhaust ports of the air tank.

[0040]The air inlet of the coarse pressure regulating valve 1 is connected with the high-pressure gas source through the gas pipeline, the air inlet of the fine pressure regulating valve 2 is connected with the air outlet of the coarse pressure regulating valve 1 through the gas pipeline, and the air inlet of the first solenoid valve 3 Connect the air outlet of the fine pressure regulating valve 2 through the gas pipeline, the air inle...

Embodiment 3

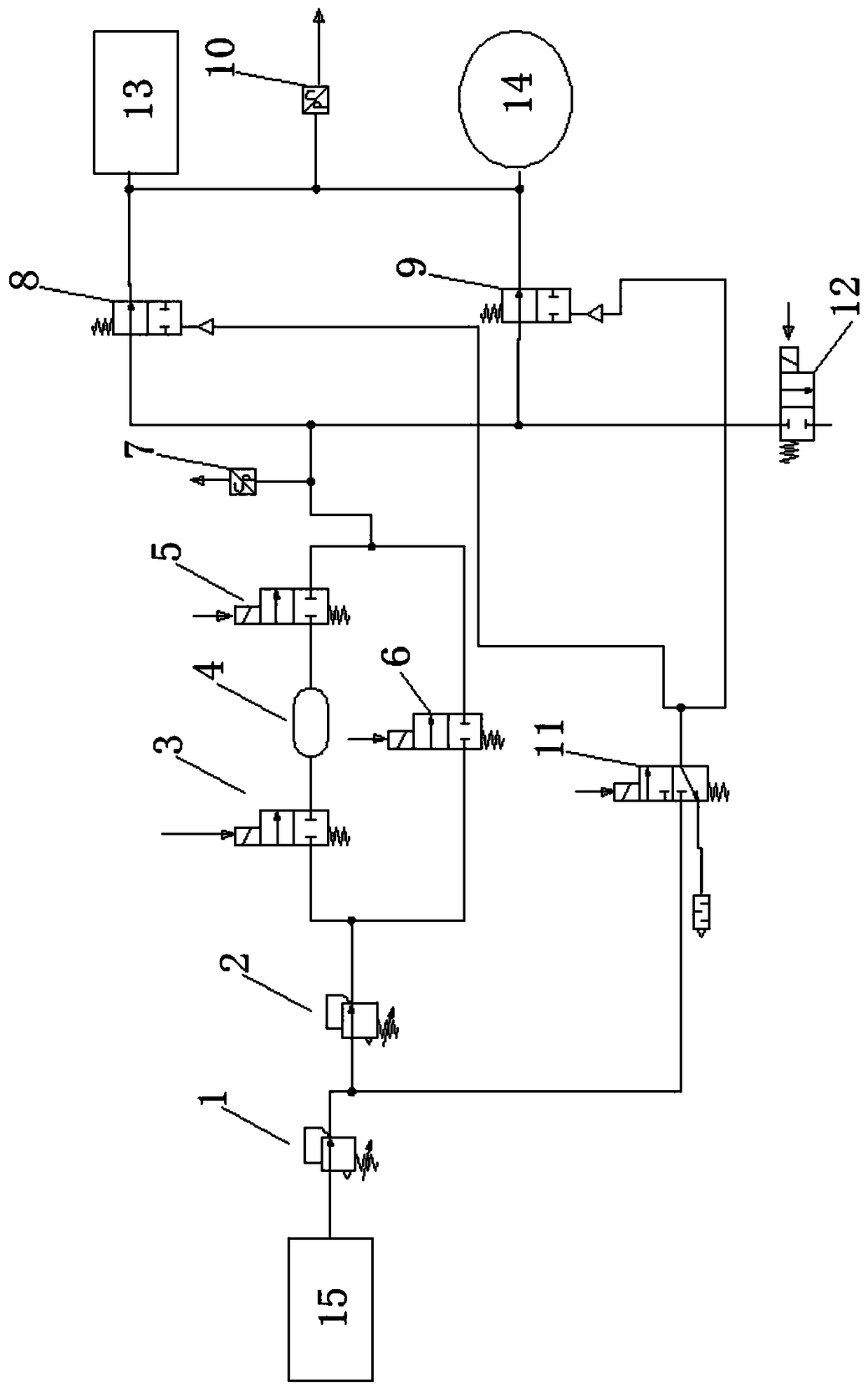

[0050] Since the differential pressure air tightness tester involved in the present invention may be used to detect larger workpieces, these larger test pieces 13 usually need to be fed with a large amount of gas to ensure the accuracy of detection, and only by buffering The speed of the device to inflate the tested part 13 and the standard part 14 is relatively slow, so on the basis of the second embodiment, a bypass solenoid valve 6 is added between the fine pressure regulating valve and the pressure sensor, as shown in the attached image 3 As shown, the bypass solenoid valve 6 is connected in parallel with the air path formed by connecting the first solenoid valve 3, the gas tank 4 and the second solenoid valve 5, and the air inlet of the bypass solenoid valve 6 is connected with the gas outlet of the fine pressure regulating valve 2 , the air outlets of the bypass solenoid valve 6 are respectively connected with the first control valve 8 and the second control valve 9 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com