Online monitoring device for monitoring electro-slag furnace water cooled cable and online monitoring method for monitoring electro-slag furnace water cooled cable

A technology of water-cooled cables and monitoring devices, which is applied in the direction of fault location, electrical program control, general control system, etc., can solve the problems of equipment impact on maintenance costs, under-maintenance, and over-maintenance of components, so as to avoid smelting interruption accidents and reduce spare parts costs , to avoid the effect of under-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

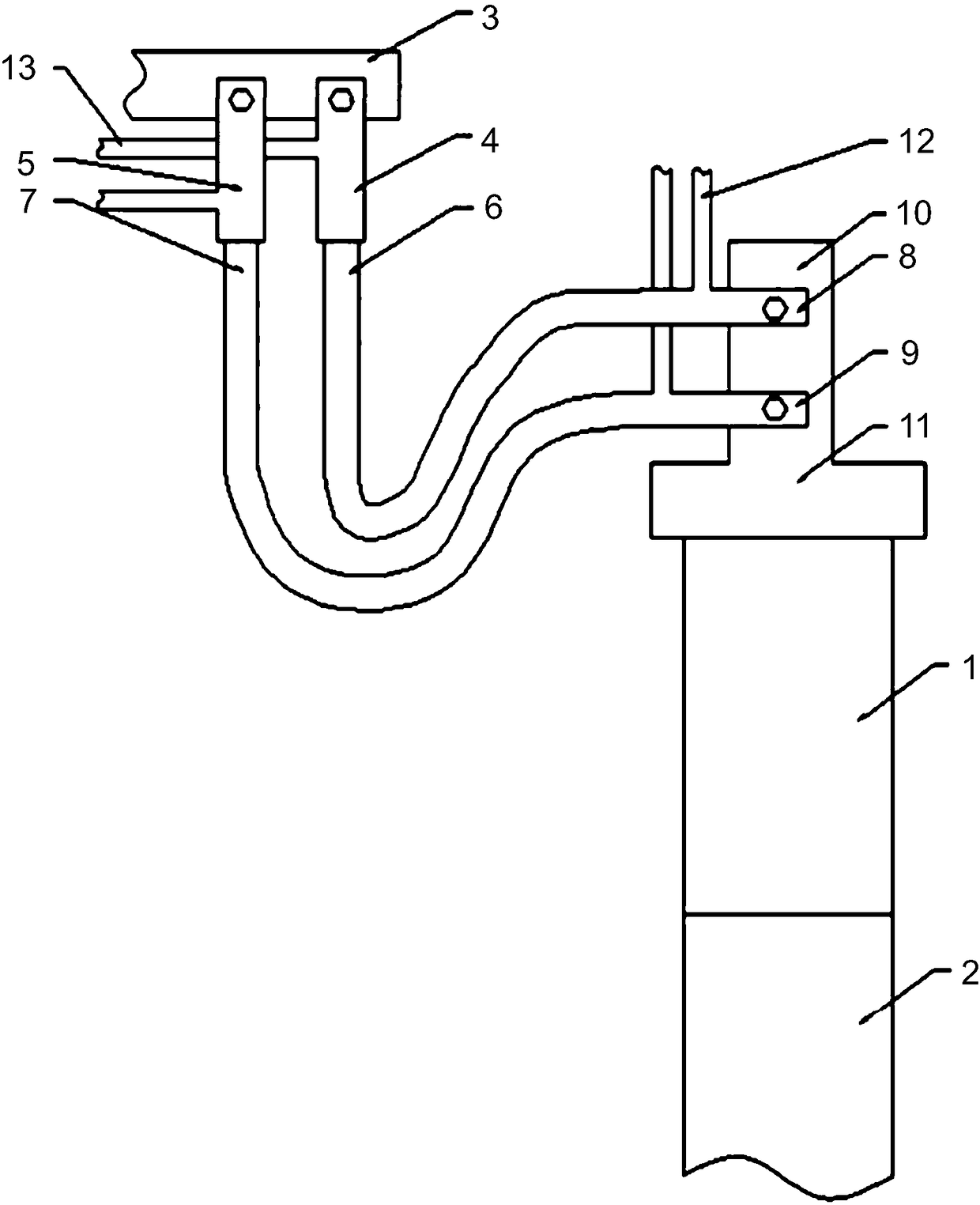

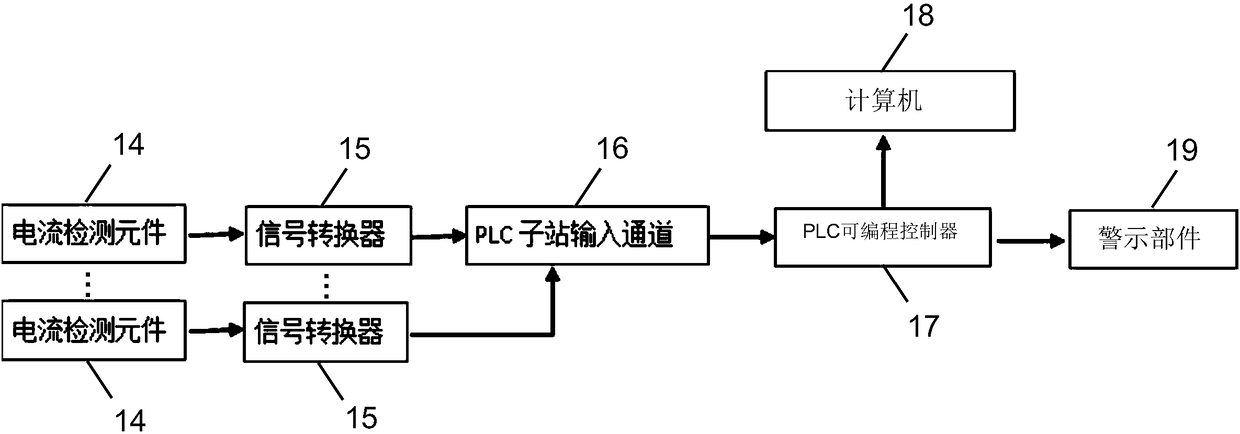

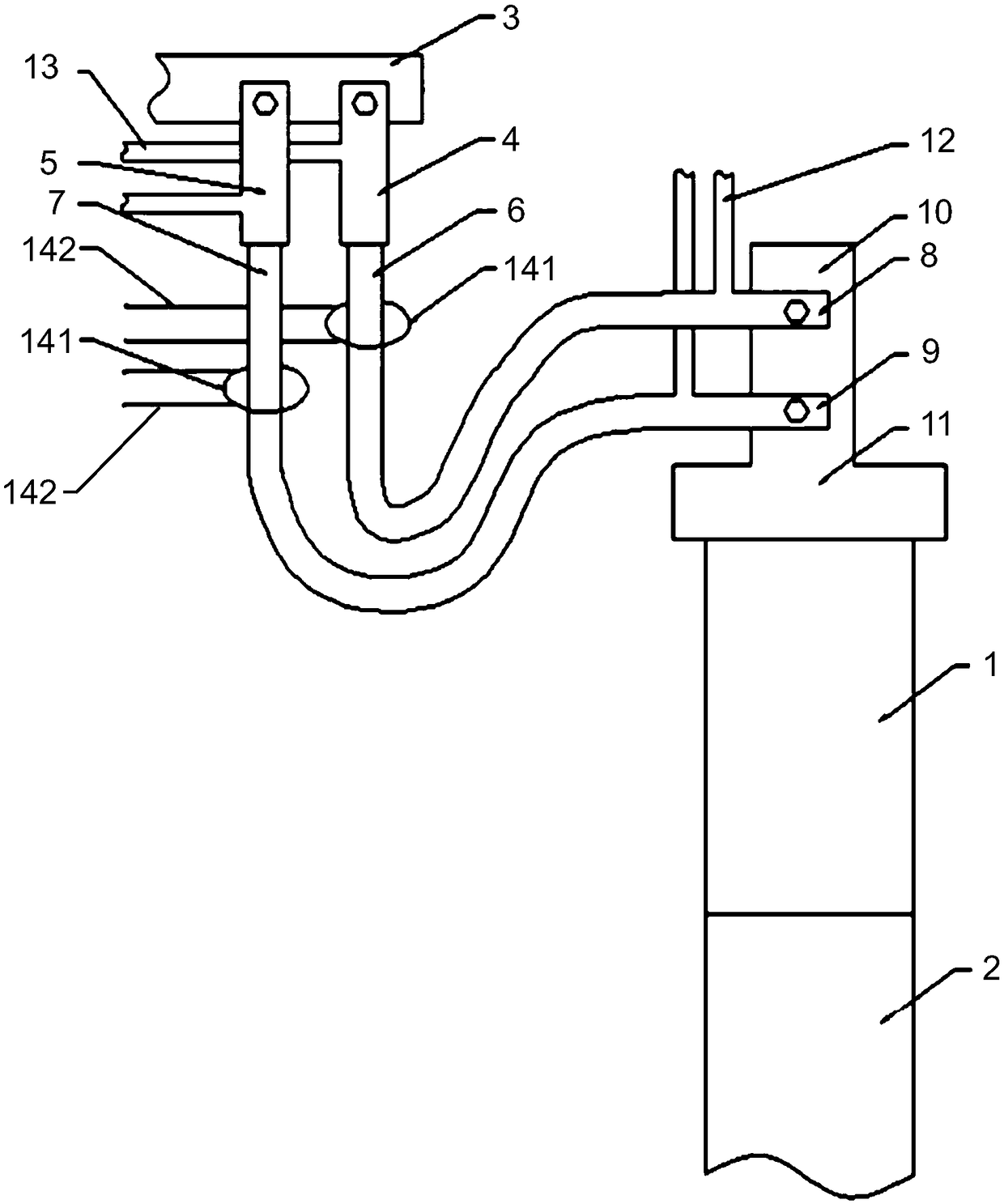

[0028] Please combine figure 2 and image 3 As shown, an online monitoring device for monitoring water-cooled cables of electroslag furnaces provided by the present invention is connected with water-cooled cables 6 and 7, and includes a current detection component 14, a signal converter 15, a PLC substation input channel 16, and a PLC Programmable controller 17 and computer 18, current detection part 14 has several, set according to the water-cooled cable quantity of electroslag truck site, the input end of each current detection part 14 is connected with every water-cooled cable respectively, signal converter 15 also has several, correspondingly set according to the quantity of current detection parts 14, the output end of current detection part 14 is connected with the input end of corresponding signal converter 15 respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com