Polycrystal geometric modeling method

A geometric modeling and multi-crystal technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of slow learning and using inp files, increased repetitive workload, cumbersome calculation steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the exemplary embodiments of the present invention are used to explain the present invention, but not as a limitation to the present invention.

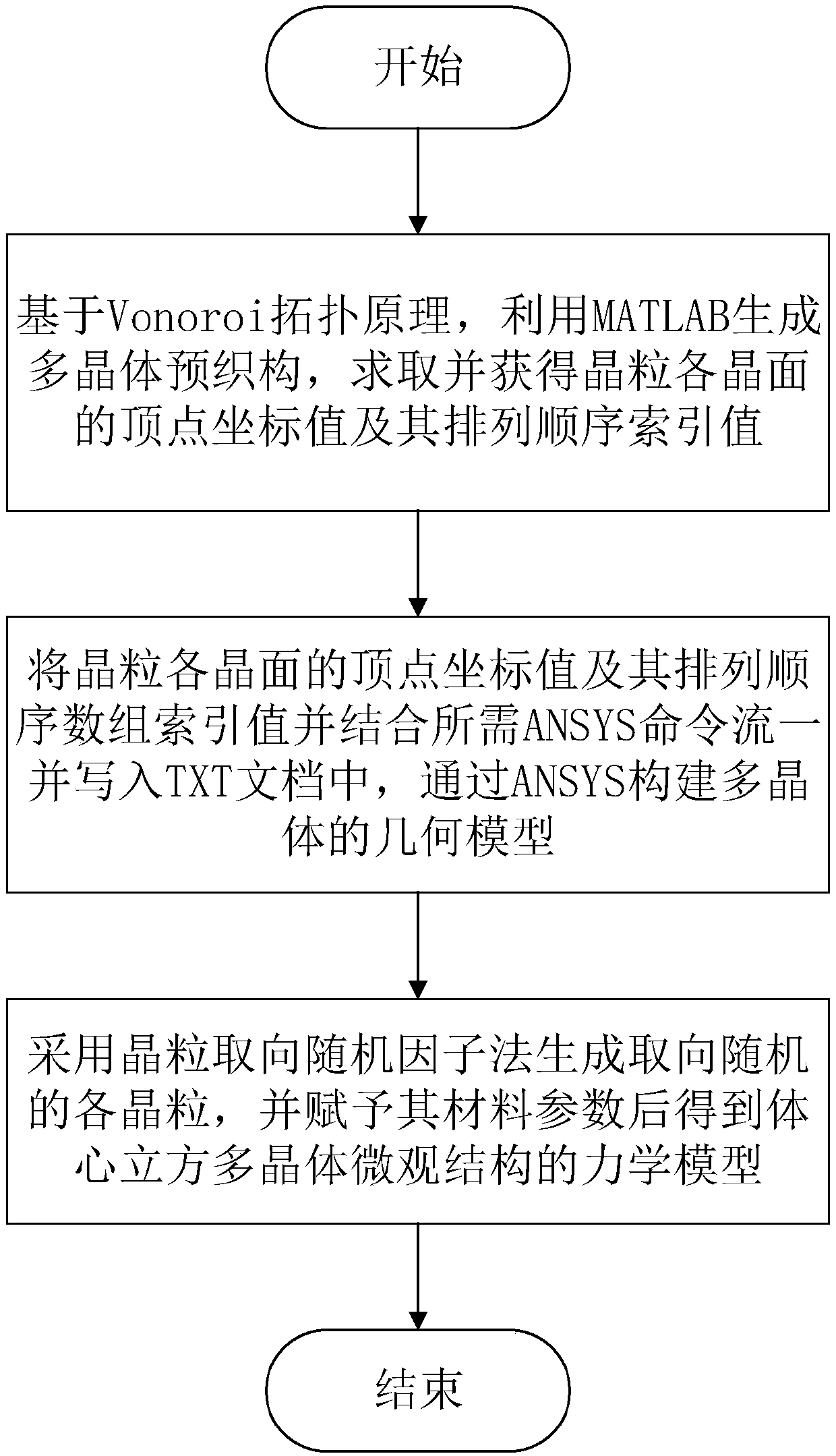

[0055] The present invention mainly has three flow processes. First, based on the topological Voronoi topology principle, use MATLAB to build a polycrystalline pre-textured model, and complete the data sorting and storage in MATLAB; then use these data to carry out solid geometric modeling in ANSYS; finally use Python to perform secondary development on ABAQUS The mechanical analysis of the polycrystalline geometric model is completed, thereby verifying the correctness of the geometric model built by this method, and laying the foundation for the subsequent research and optimization of BCC metal polycrystalline. The specific technical scheme is as follows:

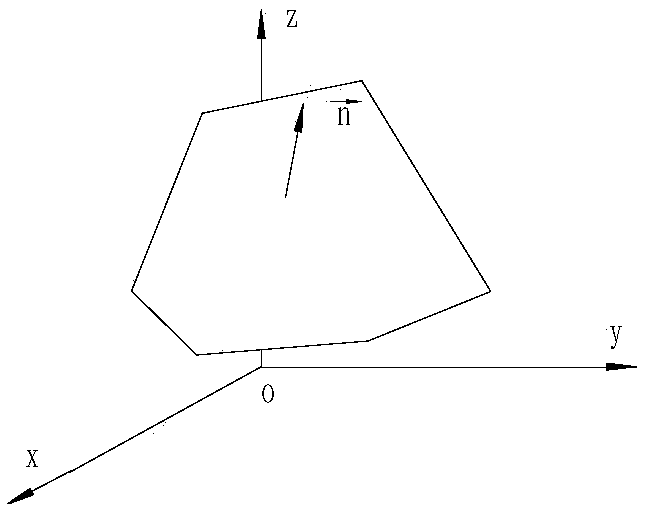

[0056] Step 1: Use MATLAB to generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com