Integrated radiator having temperature gradient

A temperature gradient, integrated technology, applied in the direction of electrical solid devices, semiconductor devices, semiconductor/solid state device components, etc., can solve the problems of cumbersome assembly, many heat dissipation parts, poor heat dissipation effect, etc., to facilitate the layout design, The effect of meeting heat dissipation needs and saving assembly procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

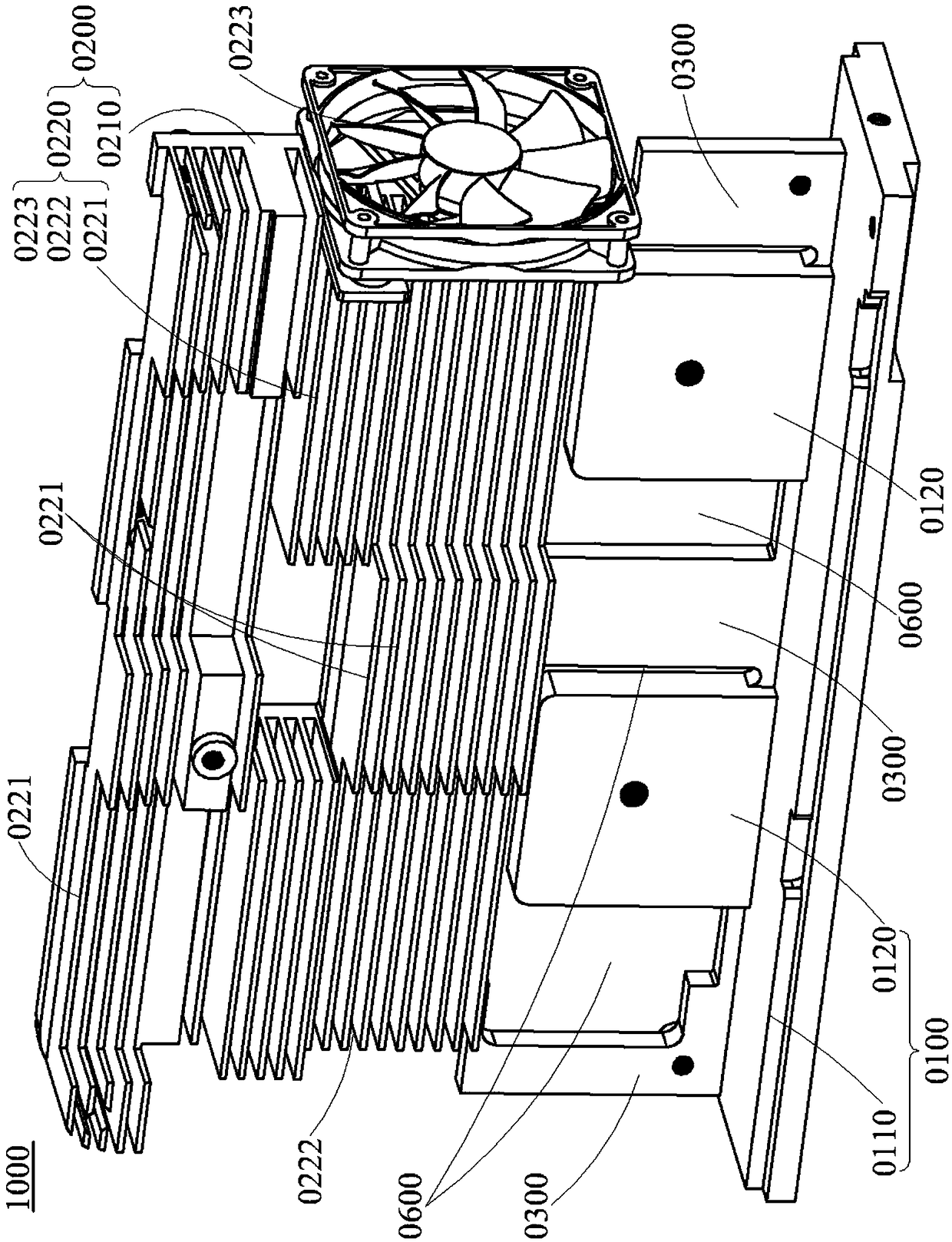

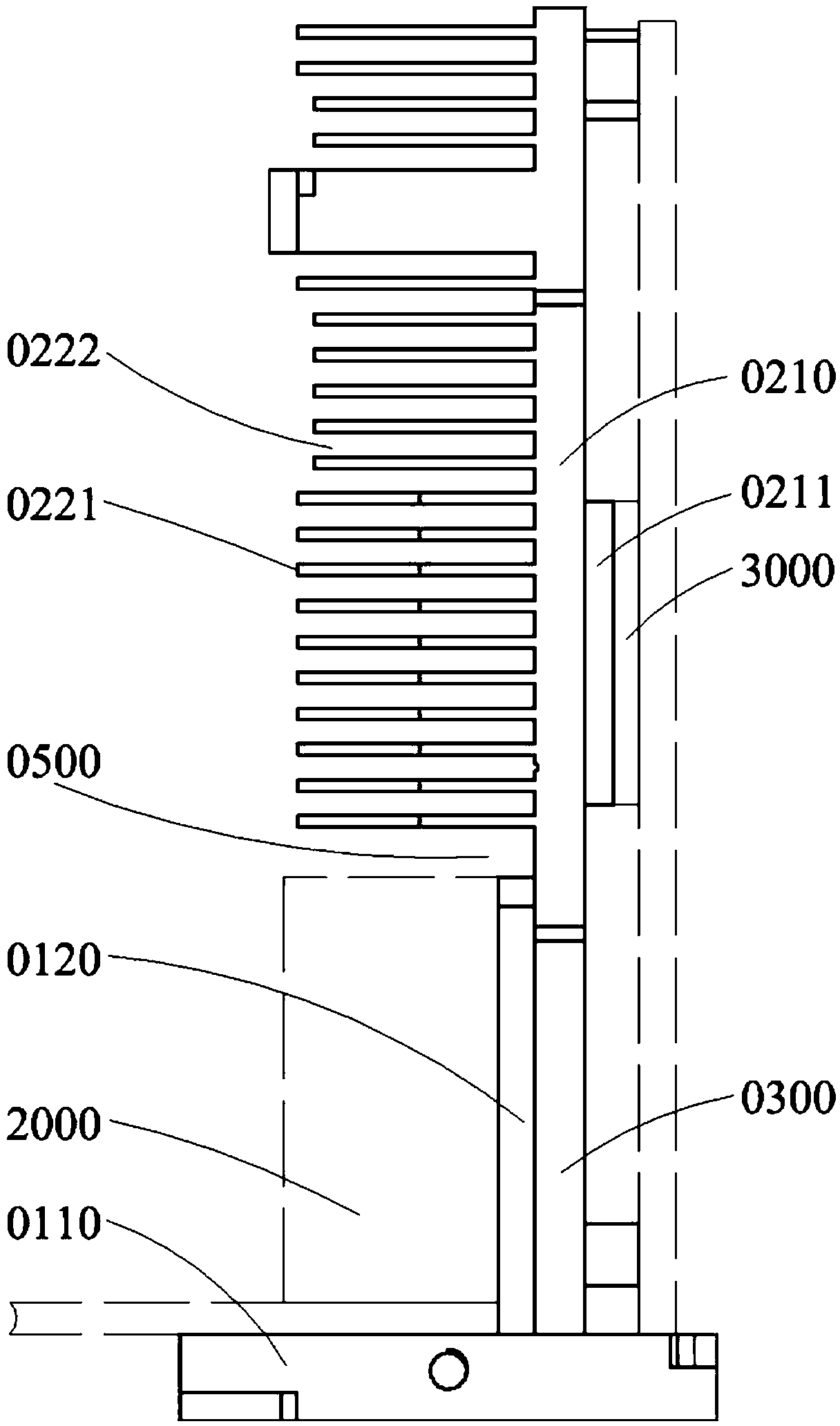

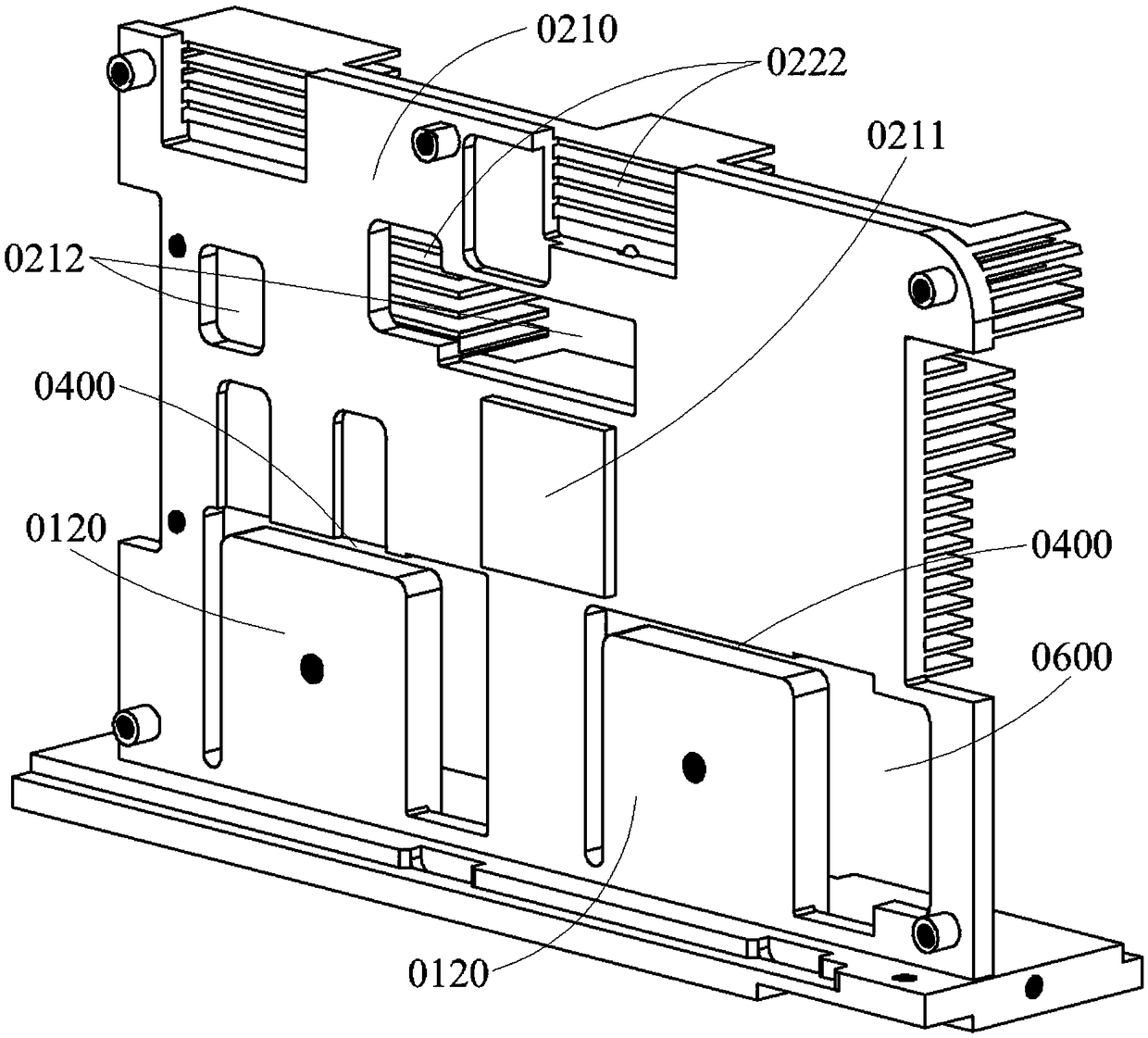

[0031] Please refer to Figure 1~2 , this embodiment discloses an integrated radiator with temperature gradient (hereinafter referred to as "integrated radiator") 1000, which is arranged between the high-temperature device 2000 and the low-temperature device 3000, and realizes the partition on the integrated structure in a thermal isolation manner Heat dissipation, forming different temperature zones with constant temperature difference and stable temperature gradient, meeting the heat dissipation requirements of the high temperature device 2000 and the low temperature device 3000.

[0032] The integrated heat sink 1000 includes a first heat dissipation unit 0100 and a second heat dissipation unit 0200 fixed integrally, and the first heat dissipation unit 0100 and the second heat dissipation unit 0200 are physically connected but thermally isolated. In other words, the first heat dissipation unit 0100 and the second heat dissipation unit 0200 are physically integrated to achie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com