Preparation method of xanthophyll nanometer emulsion

A technology of lutein nanoemulsion and lutein, applied in food science and other directions, can solve problems such as affecting the sensory properties and quality of food products, complex chemical composition, etc., and achieve easy control of the operation process, good reproducibility, and improvement of dispersive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

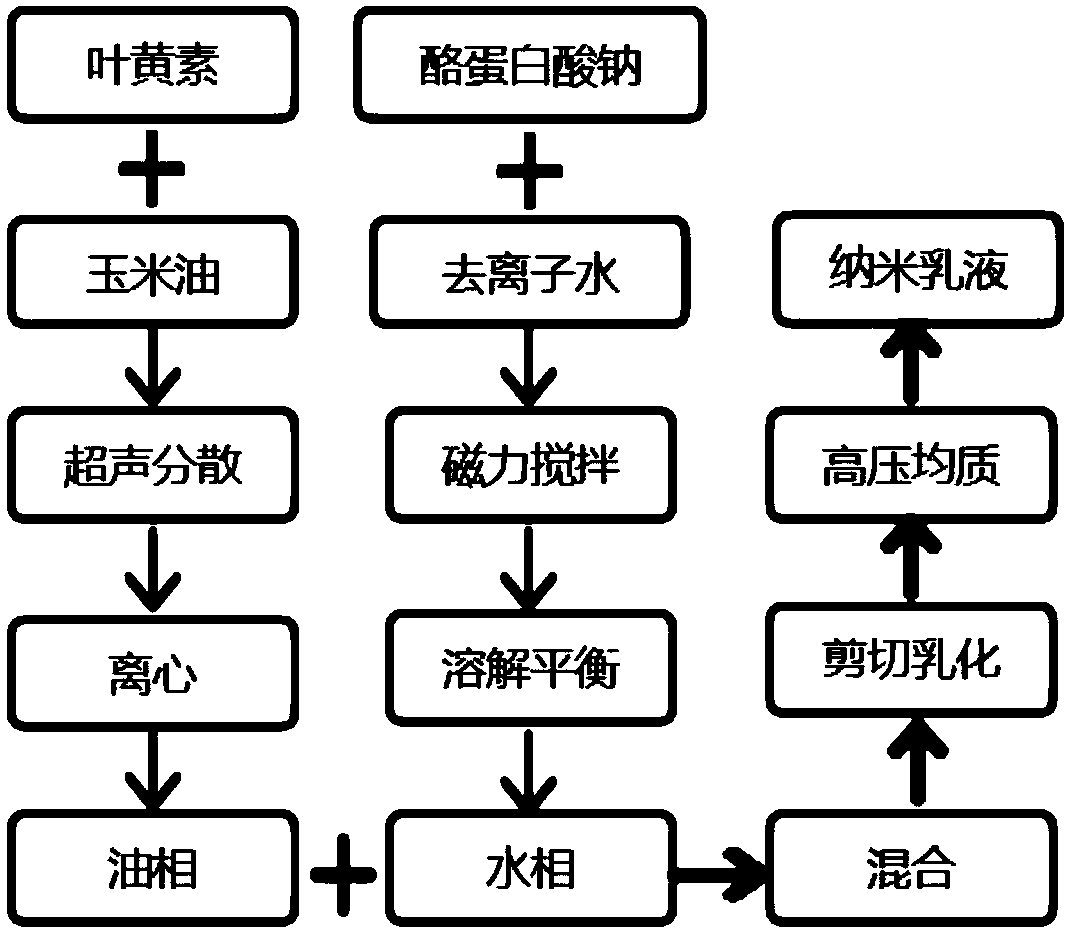

Method used

Image

Examples

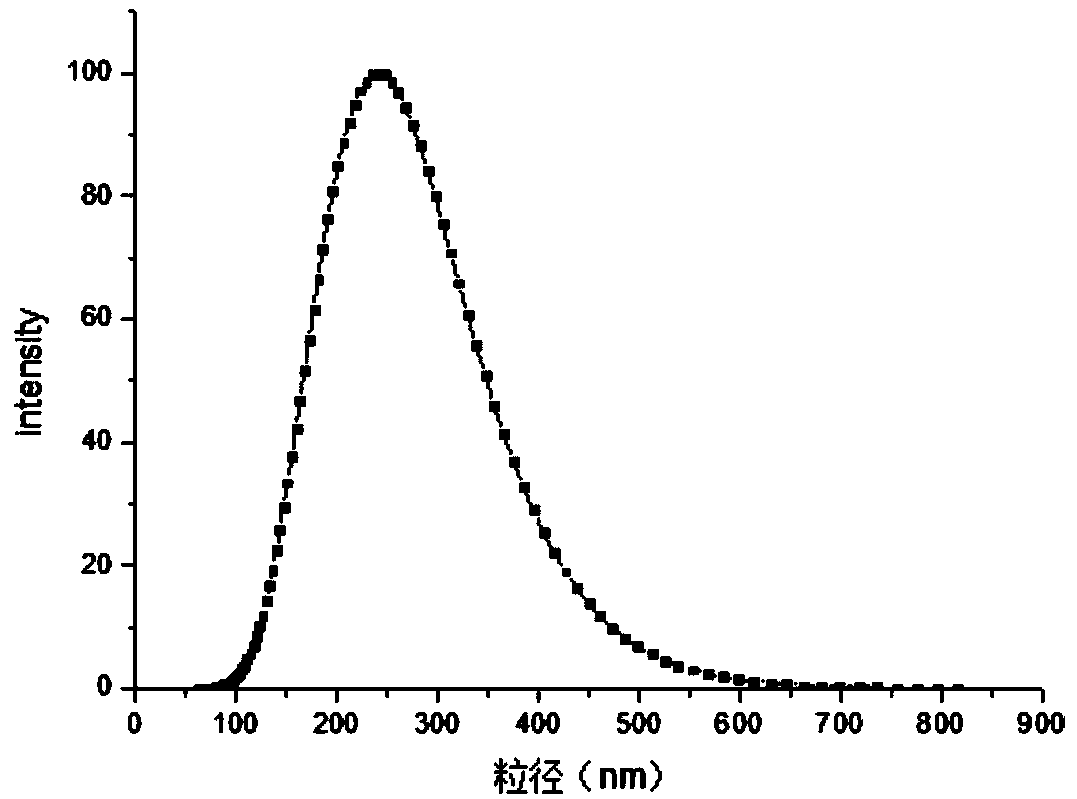

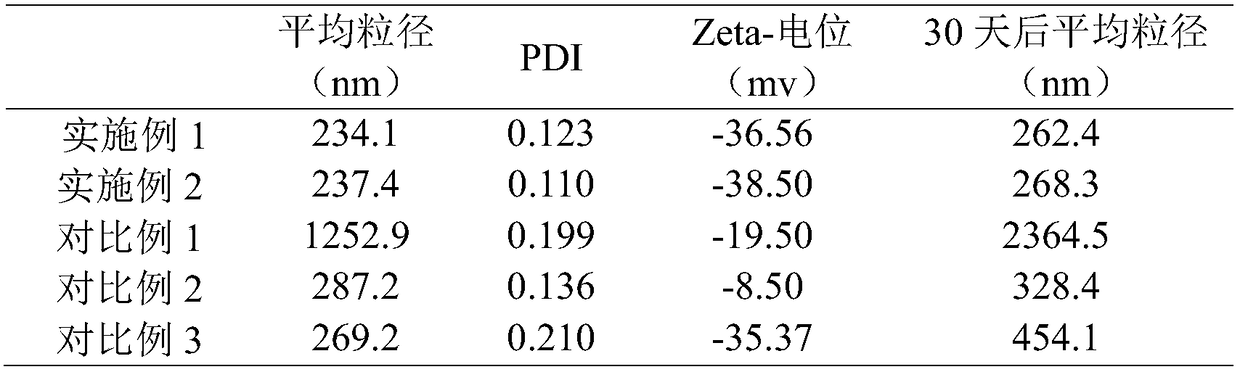

Embodiment 1

[0037] Prepare a sodium caseinate storage solution with a concentration of 5% (w / w) with deionized water, weigh 10 g of sodium caseinate powder, add deionized water to a total mass of 200 g, and stir magnetically at room temperature for 1 hour until completely dispersed , stand overnight at 4°C to completely dissolve sodium caseinate and balance; prepare lutein oil solution with corn oil, disperse it with ultrasound for 10 minutes, and then stand at 4°C in the dark for 48 hours to make it dissolve and balance, then centrifuge at 3000rpm for 15 minutes to take the supernatant saturated oil The solution is ready for use; take 27g of 5% (w / w) sodium caseinate stock solution, add deionized water to dilute to a total mass of 135g to obtain a 1% (w / w) sodium caseinate solution, take 135g of the aqueous phase and stir While adding 15g of saturated oil phase therein, after mixing evenly, use a high-speed shear emulsifier to shear and homogenize at 10000rpm for 2min to obtain a coarse e...

Embodiment 2

[0039] Prepare a sodium caseinate solution with a concentration of 2% (w / w) with deionized water, accurately weigh 3.6g of sodium caseinate powder, add deionized water to a total mass of 180g, and stir magnetically at room temperature for 1 hour to make it completely Disperse, stand overnight at 4°C to completely dissolve sodium caseinate and balance; prepare lutein oil solution with soybean oil, disperse with ultrasound for 10 minutes, and then stand at 4°C in the dark for 48 hours to dissolve and balance, then centrifuge at 3500rpm for 10 minutes to remove undissolved Lutein, take saturated oil solution for later use. Take 180g of the water phase, add 20g of lutein soybean oil solution to it, use a high-speed shear emulsifier to shear and homogenize at 8000rpm for 5min to obtain a coarse emulsion, add the above-mentioned coarse emulsion to a high-pressure homogenizer, and circulate homogeneously at 100MPa Seven times, a uniform and stable lutein nanoemulsion with controllabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com