Stirring mill with power-assisted starting component

A component and mill technology, applied in the field of grinding equipment, can solve the problems of reduced particle size uniformity of mineral powder, insufficient grinding, and affecting the use of mineral powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

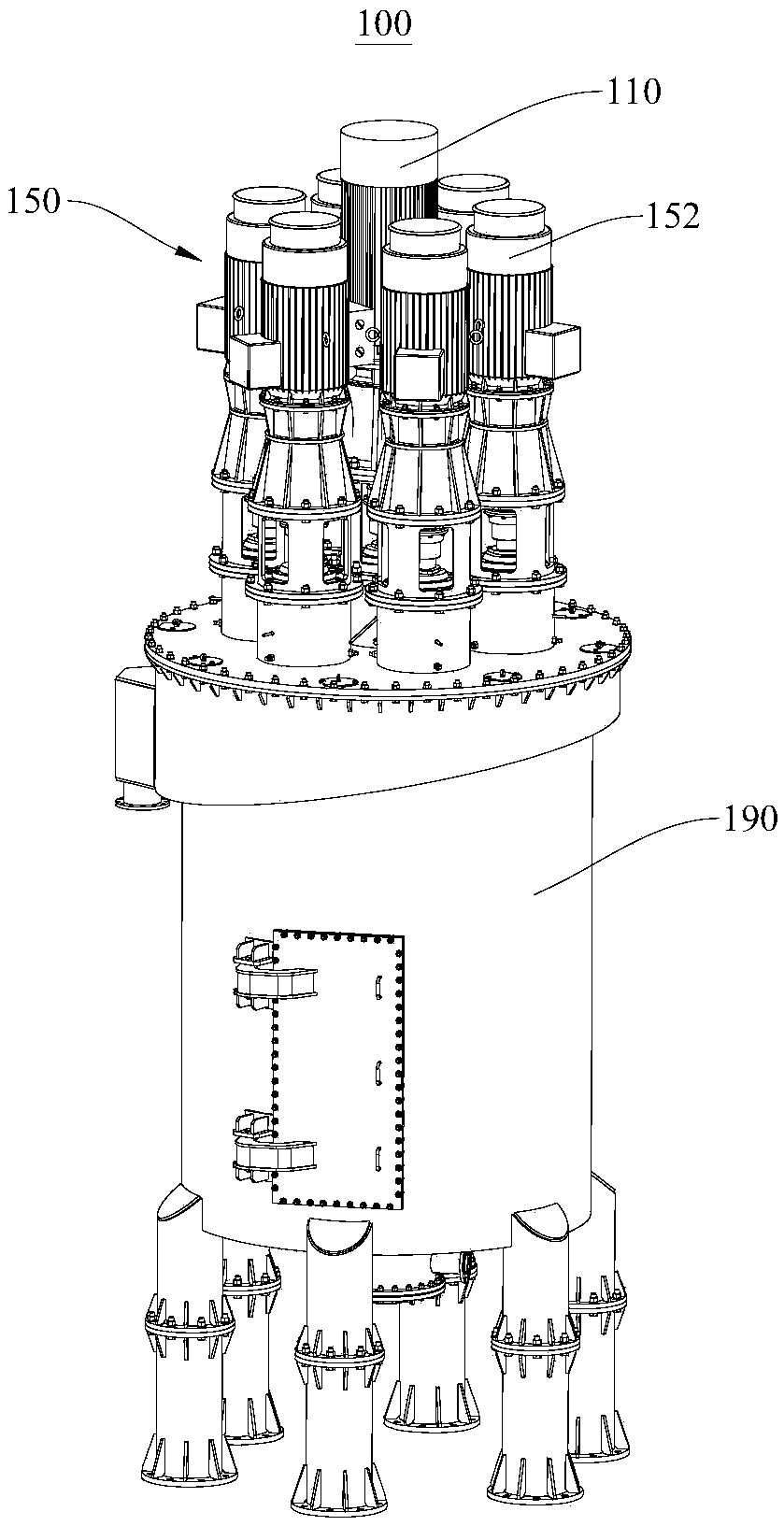

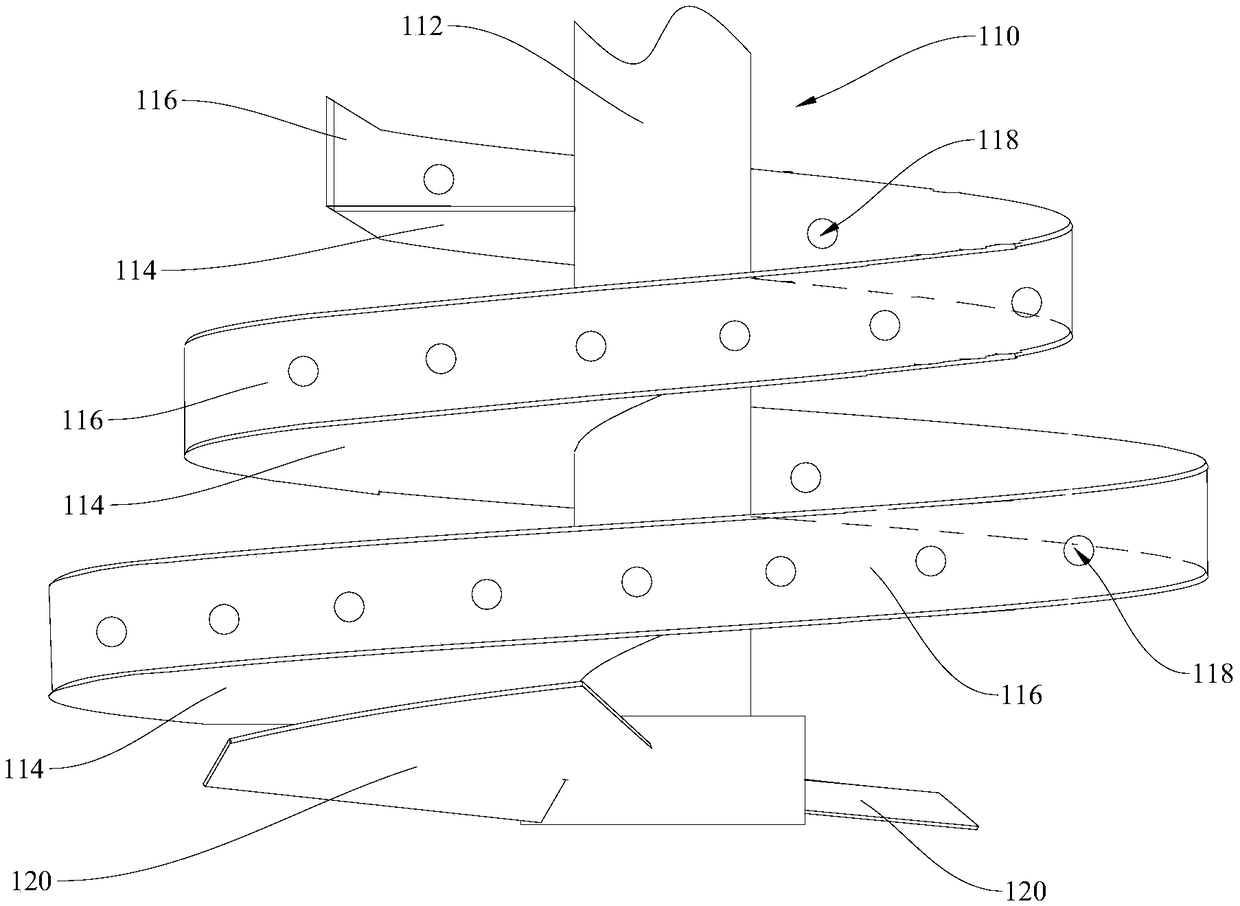

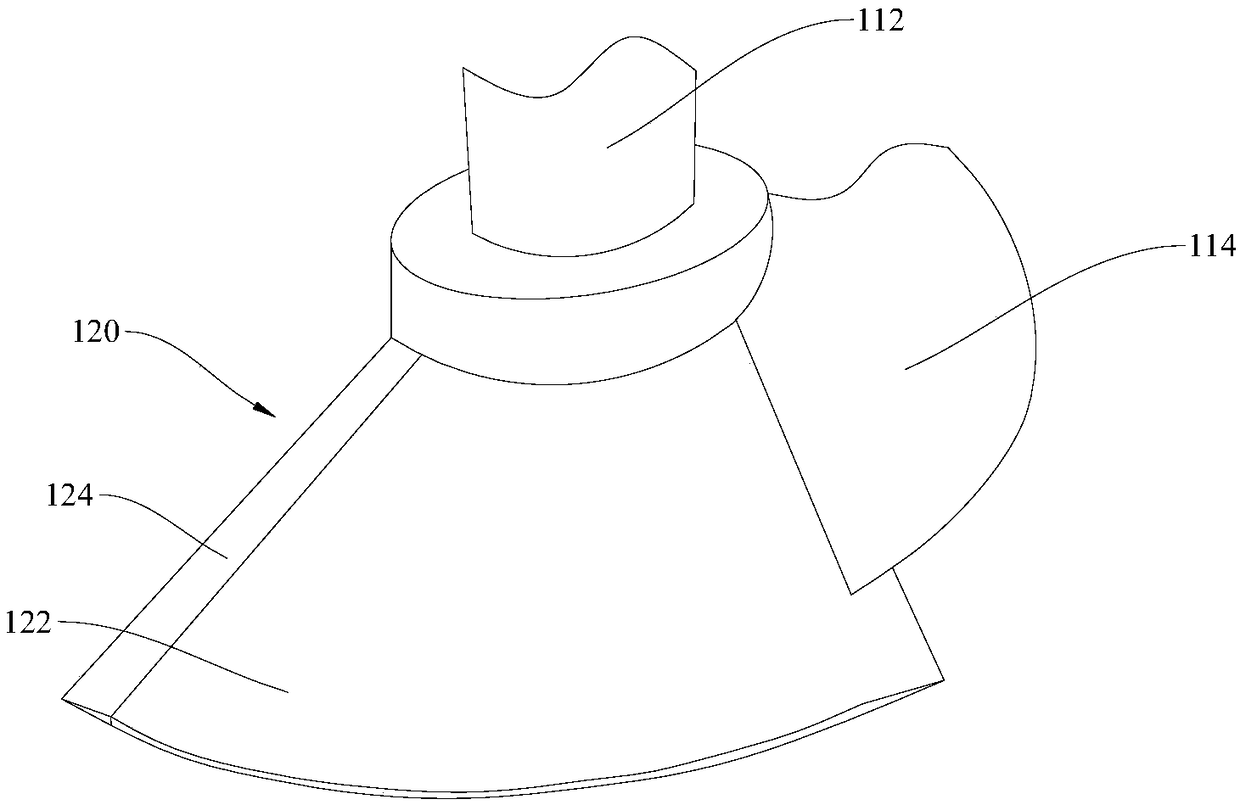

[0034] Please refer to figure 1 , figure 1 A schematic diagram of the structure of the stirred mill 100 is shown. This embodiment provides a stirring mill 100, which mainly utilizes the stirring motion of the grinding medium to produce impact, shearing, and grinding effects, so as to achieve the purpose of crushing materials.

[0035] The stirred mill 100 mainly includes a screw lift shaft 110 , a stirring assembly 150 and a barrel body 190 . Both the stirring assembly 150 and the helical lifting shaft 110 are located in the barrel main body 190 . Such as figure 1 As shown, both the screw lifting shaft 110 and the stirring assembly 150 are arranged to be partly located inside the cylinder main body 190 and partially located outside the cylinder main body 190 . The part located outside the cylinder main body 190 is convenient for transmission connection with driving equipment such as a motor, so that the screw lifting shaft 110 and the stirring assembly 150 can rotate.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com