Precise automatic revolving riveting machine

A riveting machine and automatic technology, applied in the field of precision automatic riveting machines, can solve the problems of low degree of automation, lack of lighting and magnifying observation structure, inconvenient waste collection, etc., to improve labor efficiency, improve automation, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

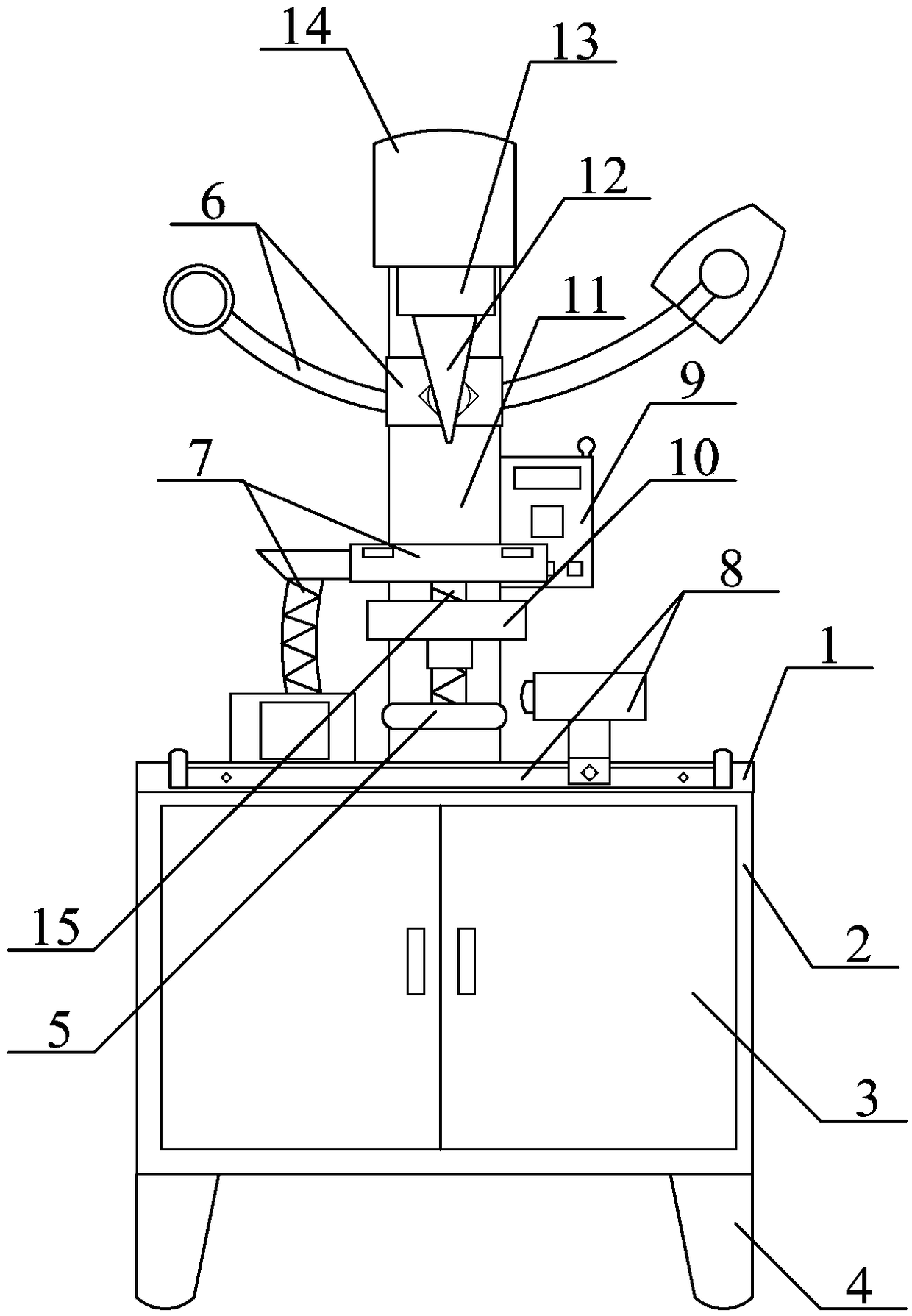

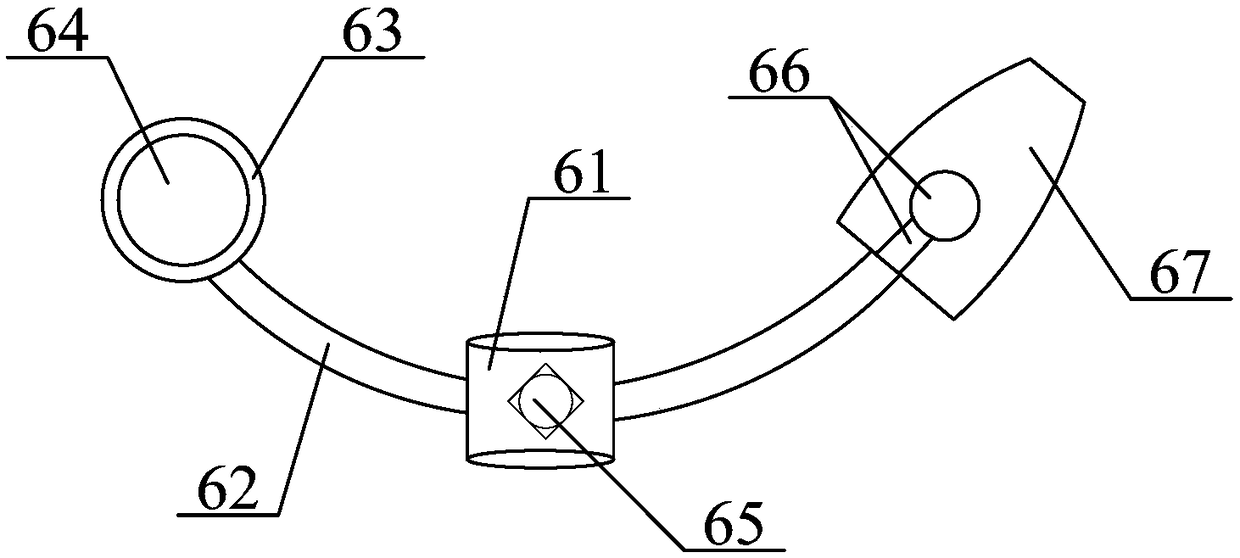

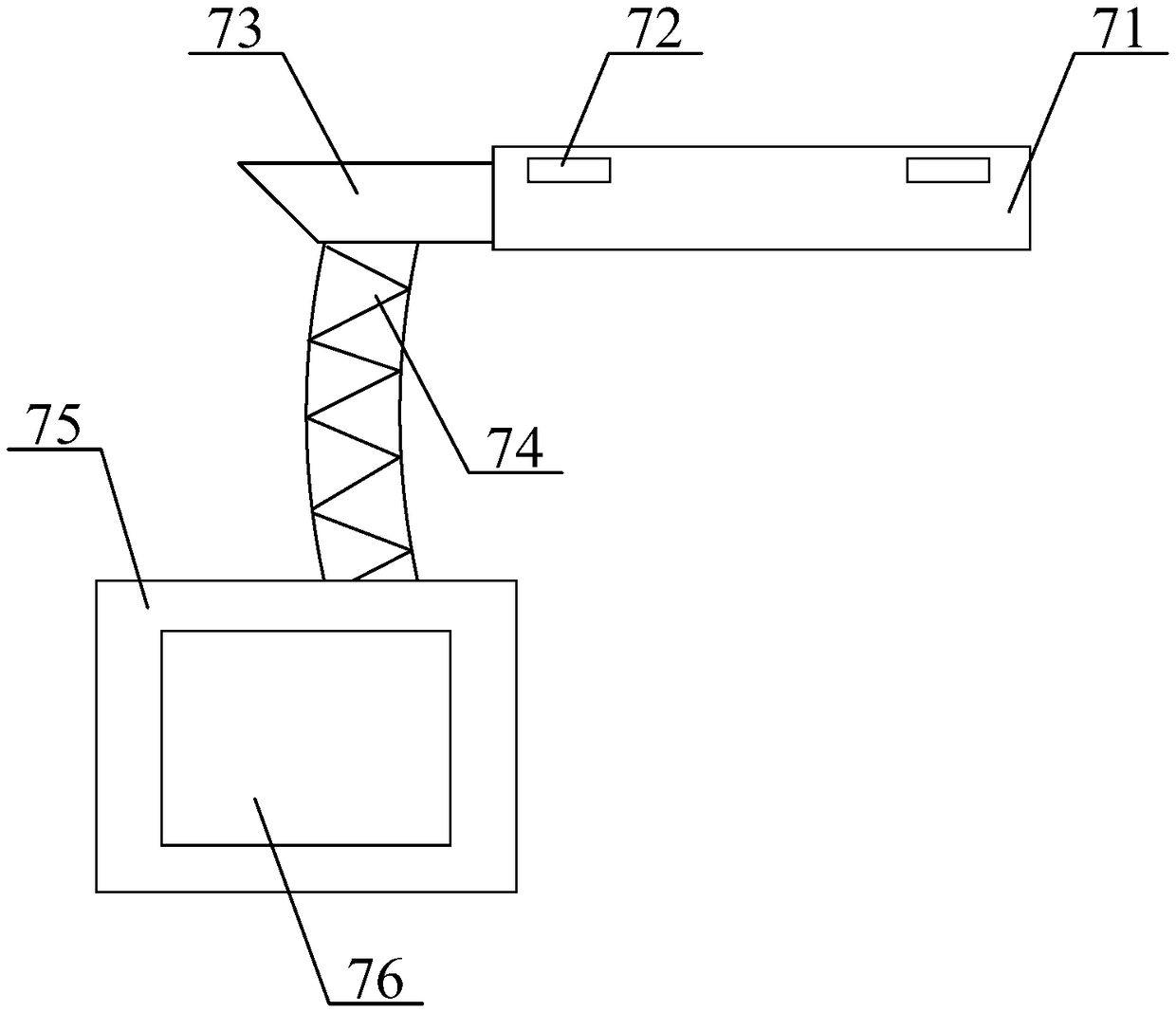

[0041] as attached figure 1 to attach Figure 6 shown

[0042] The present invention provides a precision automatic riveting machine, which includes a riveting table 1, a tool box 2, a door 3, a support seat 4, an adjusting hand wheel 5, an adjustable and enlarged lighting sleeve structure 6, and a waste recycling operation panel structure 7 , a sliding tool box structure 8, a control cabinet structure 9, a fixed base 10, a support column 11, a riveting head 12, a hydraulic telescopic cylinder 13, a rotating motor 14 and a screw lever 15, and the riveting workbench 1 is bolted to the toolbox 2; the door 3 is respectively hinged on the left and right sides of the front surface of the tool box 2; the support base 4 is bolted to the four corners of the lower surface of the tool box 2; The wheel 5 is threadedly connected to the lower surface of the screw lever 15; the adjustable magnifying lighting sleeve structure 6 is sleeved on the upper position of the outer surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com