A long nozzle sealing ring

A sealing ring and shroud technology, which is applied in metal processing equipment, manufacturing tools, casting melt containers, etc., can solve the problems of fiber sealing ring surface roughness, fiber structure damage and brittleness, and easy to become fine powder, etc., to achieve The effect of smooth surface, less breakage and less fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

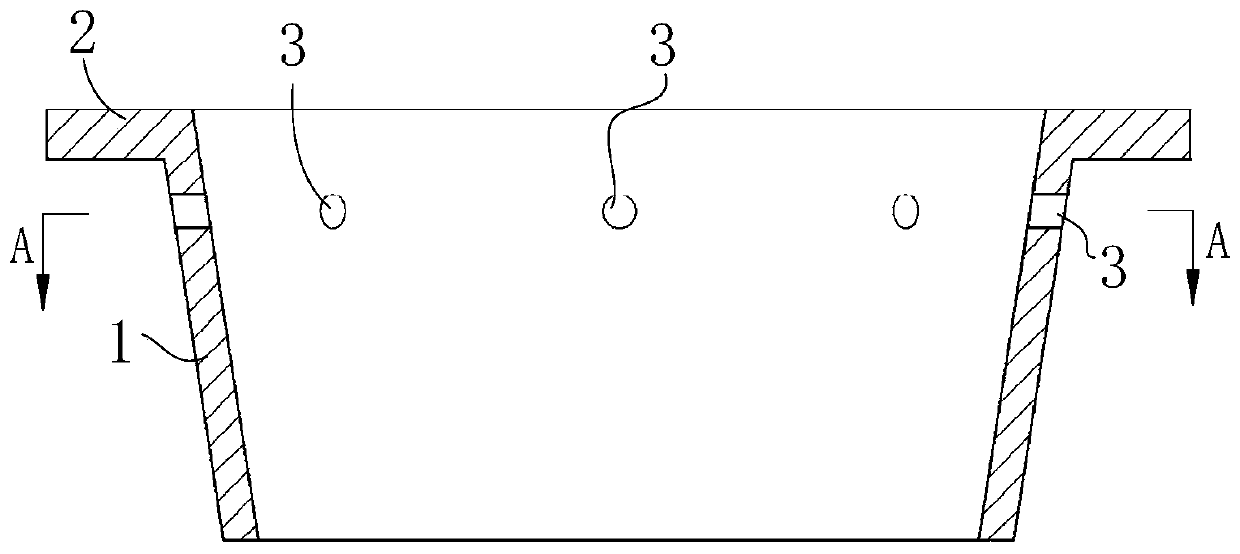

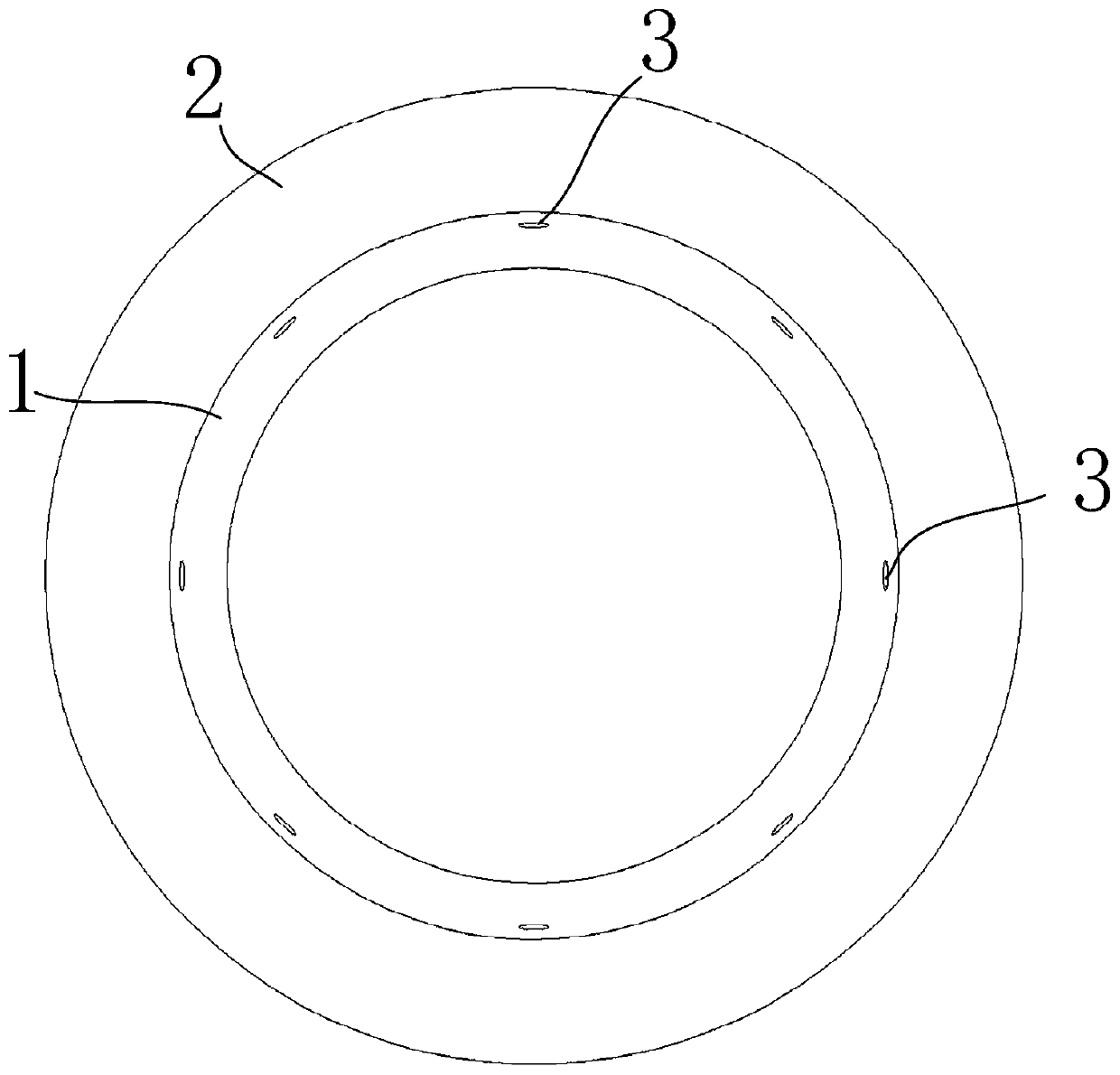

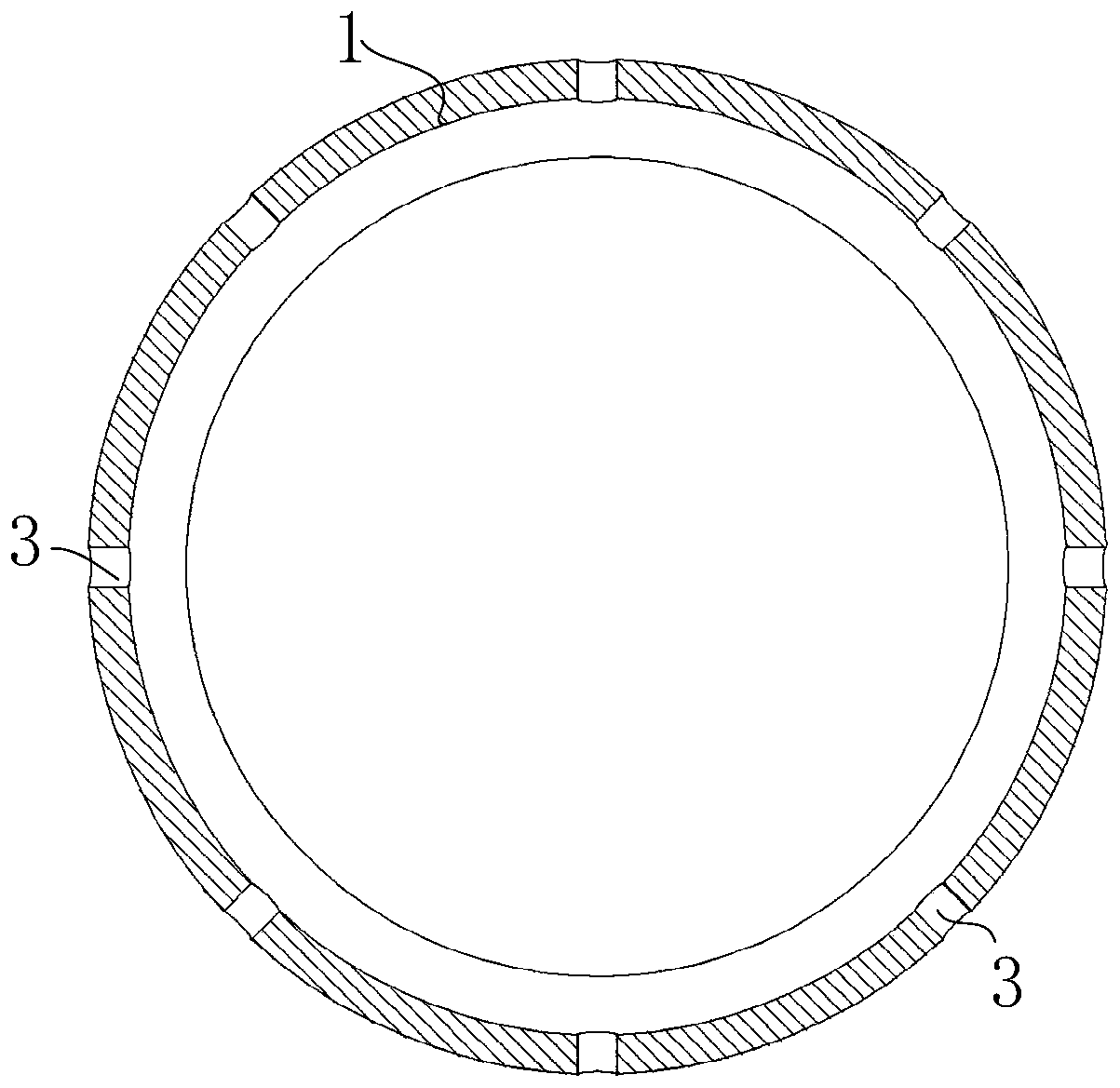

[0021] Embodiment 1, the substrate of the shroud sealing ring is made of zirconium-containing aluminum silicate fiber material, and the composition of the zirconium-containing aluminum silicate fiber material contains 59.6% Al in mass percent 2 o 3 , 25% SiO 2 , 0.2% Fe 2 o 3 , 0.2% Li 2 O, 5% Si 3 N 4 and 10% ZrO 2 . The matrix made of this proportioned fiber material is exposed to a high temperature environment of 1500°C for 6 hours. During this process, the matrix first expands and expands in volume, and as part of the material in the material is oxidized at high temperature, its volume will gradually shrink. Finally, it is verified that its thermal expansion rate is - 4.5-4.5%. The actual stable use temperature that can be achieved is 1300℃~1350℃. The surface of the matrix is smooth, the fiber structure is stable at high temperature, the elongation at break is 0.6%, and the matrix is not easy to crack. In order to have better sealing performance during assemb...

Embodiment 2

[0022] Embodiment 2, the matrix of the shroud sealing ring is also made of zirconium-containing aluminum silicate fiber material, and the composition of the zirconium-containing aluminum silicate fiber material contains 60% Al by mass percentage. 2 o 3 , 21.6% SiO 2 , 0.1% Fe 2 o 3 , 0.3% Li 2 O, 7% Si 3 N 4 and 11% ZrO 2 . Similarly, the matrix made of this proportioned fiber material was placed in a high-temperature environment of 1500°C for 6 hours. During this process, the matrix first expands and expands in volume, and as part of the material in the material is oxidized at high temperature, its volume will gradually shrink. Finally, it is verified that its thermal expansion rate is -4.2 to 4.2%. The actual stable use temperature that can be achieved is 1320 ° C ~ 1360 ° C. The surface of the matrix is smooth, the fiber structure is stable at high temperature, the elongation at break is 0.6%, and the matrix is not easy to crack. In order to have better sealin...

Embodiment 3

[0023] Embodiment three, the composition of the zirconium-containing aluminum silicate fiber material of the matrix contains 58.65% Al by mass percentage 2 o 3 , 20% SiO 2 , 0.35% Li 2 O, 8% Si 3 N 4 and 13% ZrO 2 . Similarly, the matrix made of this proportioned fiber material was placed in a high-temperature environment of 1500°C for 6 hours. During this process, the matrix first expands and expands in volume, and as part of the material in the material is oxidized at high temperature, its volume will gradually shrink. Finally, it is verified that its thermal expansion rate is -4.0 to 4.0%. The actual stable use temperature that can be achieved is 1330 ° C ~ 1370 ° C. The surface of the matrix is smooth, the fiber structure is stable at high temperature, the elongation at break is 0.6%, and the matrix is not easy to crack. In order to have better sealing performance during assembly, a thin layer of graphite is also coated on the inner and outer surfaces of the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com