Welding fixture having noise reduction and dust collection functions and used for automobile production machining

A welding fixture and functional technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of metal dust noise, physical and mental health threats of workshop personnel, etc., to improve noise reduction effect, improve flexibility and stability , Improve the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

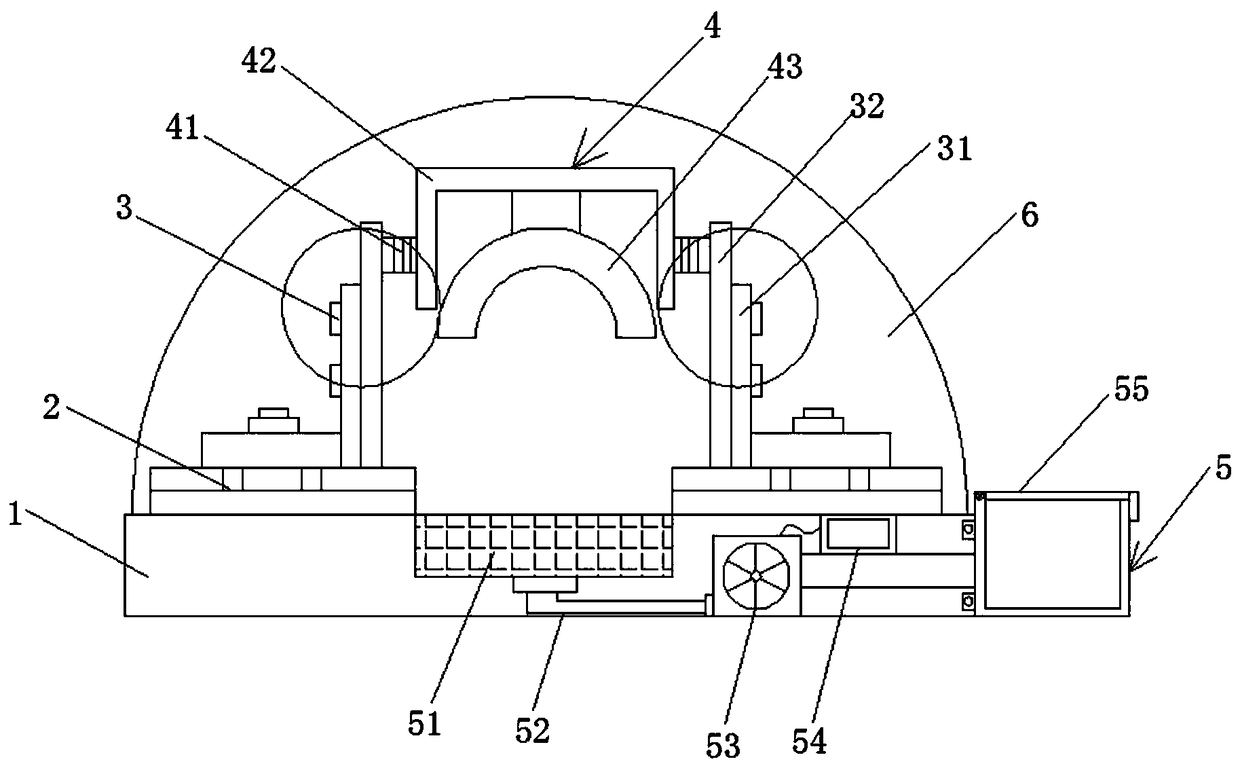

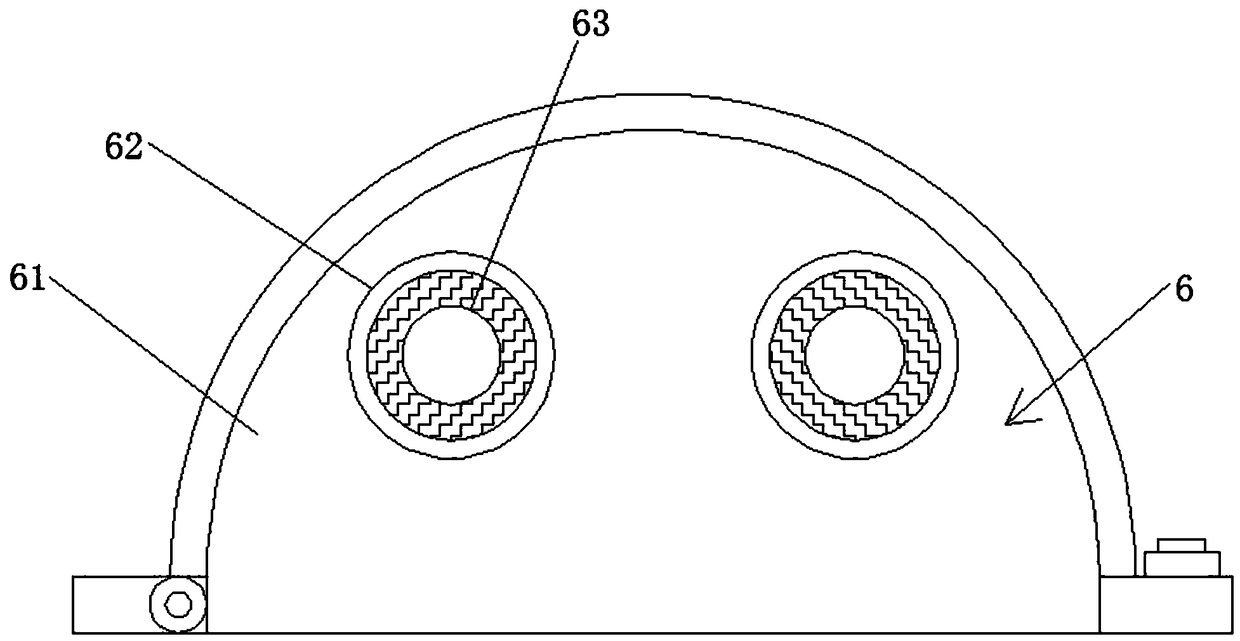

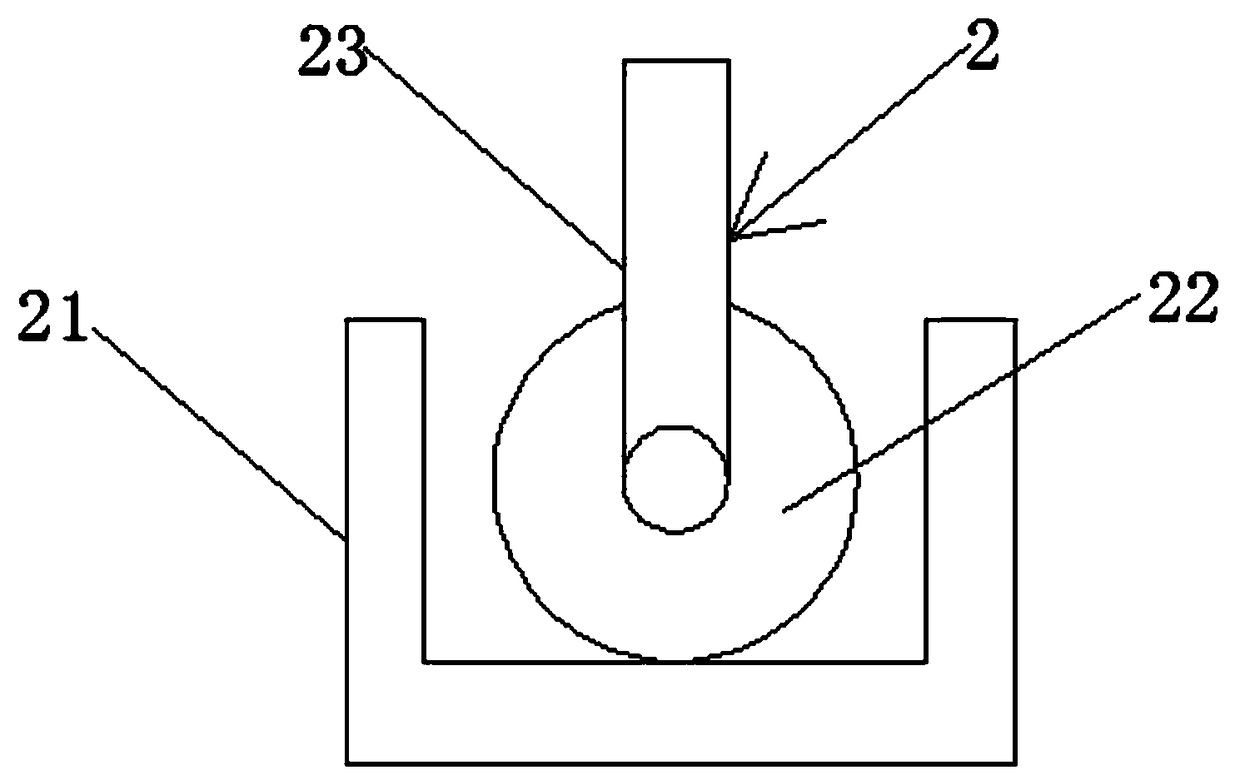

[0021] see Figure 1-3 , the present invention provides a technical solution: a welding fixture for automobile production and processing with noise reduction and dust collection functions, including a base 1, a sliding device 2, a splint 3, a snap ring device 4, a dust removal device 5 and a noise reduction cover 6. A sliding device 2 is provided on the upper side of the base 1. The sliding device 2 is connected to the splint 3 on the upper side through a connecting rod 23. The inner side of the splint 3 is movably connected to the snap ring device 4. The lower side of the snap ring device 4 There is a dust removal device 5 directly below, the dust removal device 5 is located inside the base 1, and the noise reduction cover 6 is fixed on the outside of the base 1 in a detachable manner;

[0022] The dust removal device 5 is composed of a dust removal tank 51, an air extraction pipe 52, an exhaust fan 53, a motor 54 and a dust storage box 55. The dust removal tank 51 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com