Working method of breadth-adjustable paper cutter knife set

A working method and paper cutter technology, applied in metal processing and other directions, can solve the problems of time-consuming, labor-intensive and unstable precision of knives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

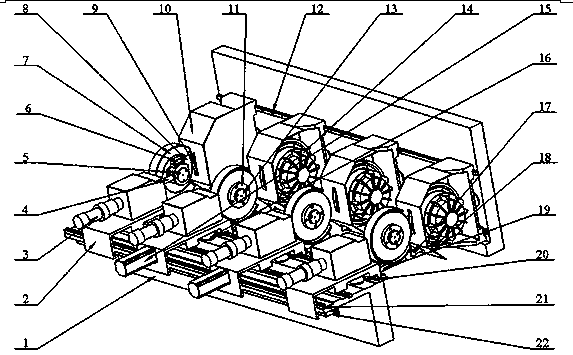

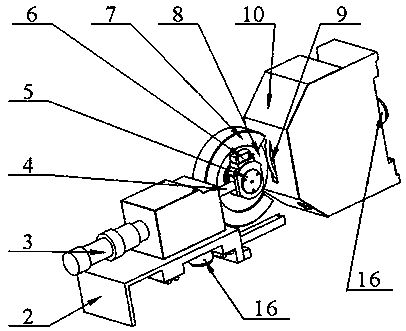

[0070] refer to Figure 7 , in the first embodiment, the cutter group of the paper cutter includes a five-component cutter group, which is divided into the first, second, third, third, and fifth slitting knife groups from right to left, and the first slitting knife group The second, third, fourth, and fifth slitting knife groups all use amplitude-modulated slitting knife groups. The first slitting knife group is not equipped with X-axis precise displacement devices for the workbench. , the rest of the structure is the same as the amplitude modulation cutting knife group.

[0071] In this embodiment, the openable and closable connection device is adopted as a group of connection devices connected to the docking base 19 through the docking cylinder rod 17 of the docking cylinder 18; the docking cylinder 18 and the docking base 19 are respectively installed on On the two cutter assemblies of the cutter group; the docking cylinder 18 can be installed on the active knife shell 10,...

no. 2 example

[0092] refer to figure 1 , Figure 8 , as a variant of the present invention, in the second embodiment, the slitting knife group is divided into the first slitting knife group, the second slitting knife group, the third slitting knife group, and the fourth slitting knife group; wherein, The first and fourth slitting knife groups are fixed slitting knife groups, and the second and third slitting knife groups are amplitude-modulated slitting knife groups.

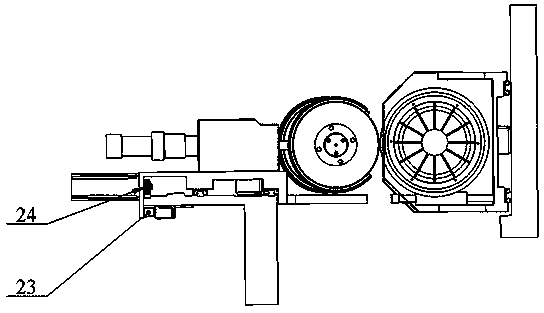

[0093] The first slitting knife group is fixedly installed at the beginning of the grating ruler 22; the first slitting knife group does not have a grating reading head 23; the displacement of the driven knife face of the first slitting knife group relative to the laser sensor measuring point is S 1 ;The X-axis width from the laser sensor measurement point of the first slitter group to the zero point of the grating ruler is L 1 , L 1 is a fixed width;

[0094] The second slitting knife group is an amplitude modulation sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com