Novel tailstock type axisymmetric multi-propeller vertical take-off and landing unmanned aerial vehicle

A propeller and tailstock type technology, applied in the aviation field, can solve the problems of low cruising speed, large aerodynamic resistance, maneuverability and safety that cannot meet the needs of special occasions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

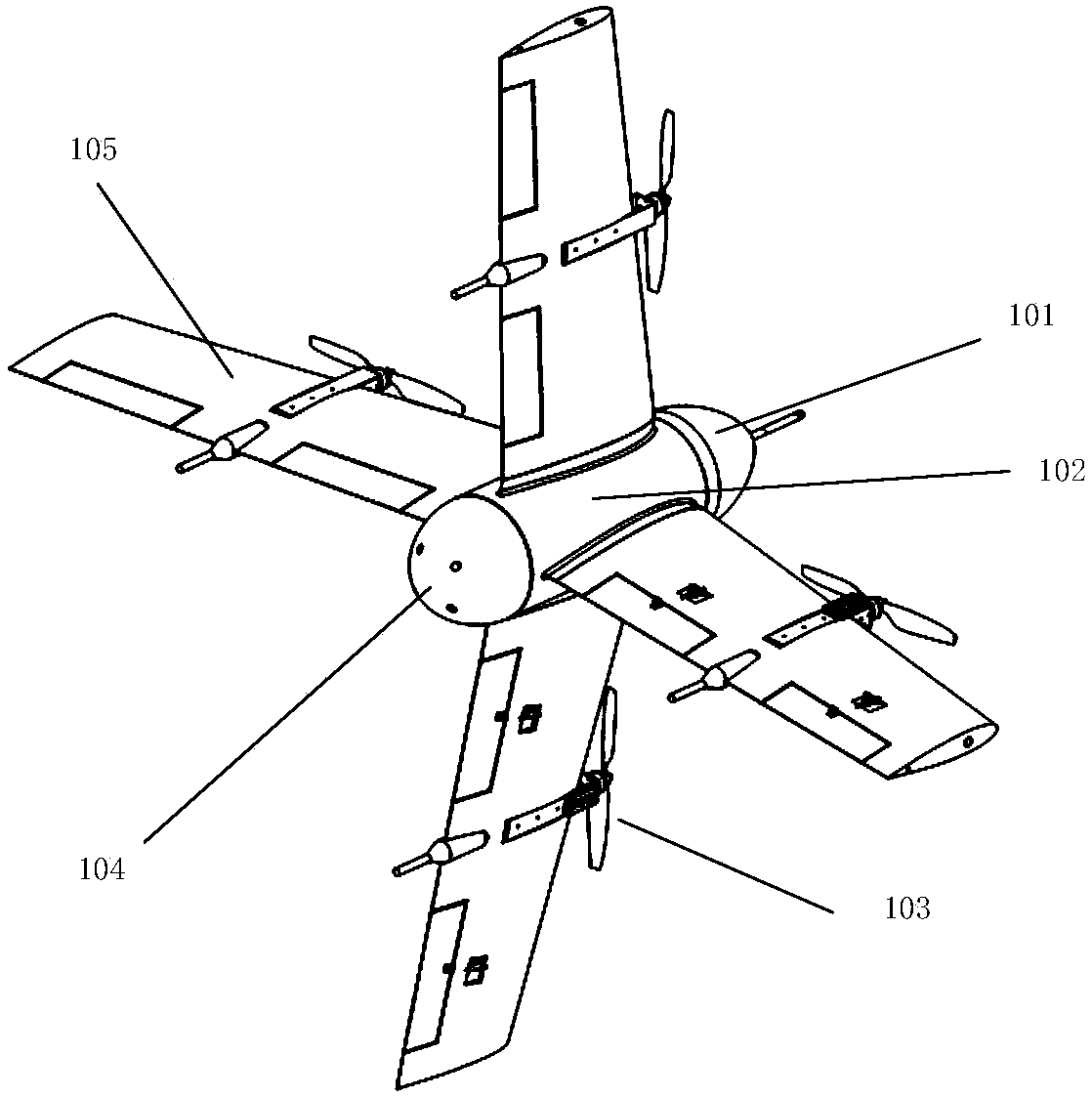

[0022] Such as figure 1 As shown, the novel tailstock type axisymmetric multi-propeller vertical take-off and landing drone of the present invention includes a fuselage assembly 102, a head cover assembly 101, a tail cover assembly 104, a power propeller assembly 103, and a symmetrical wing assembly 105. The wing components are evenly installed around the fuselage in a cross-symmetrical structure. The aerodynamic layout of this symmetrical structure can make the UAV have strong maneuverability. The head cover and tail cover components are respectively installed at the front and rear ends of the fuselage. The power propeller assembly is fixed at the middle section of the wing through the installation slot 601 on the wing, and the installation method of the symmetrical wing and the power propeller assembly makes the power propeller assembly also have a cross-symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com