Mass concrete temperature control system

A technology of mass concrete and temperature control system, applied in construction, infrastructure engineering and other directions, can solve the problems of poor control accuracy, time-consuming and laborious, and achieve the effect of solving time-consuming and laborious, reasonable structure and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

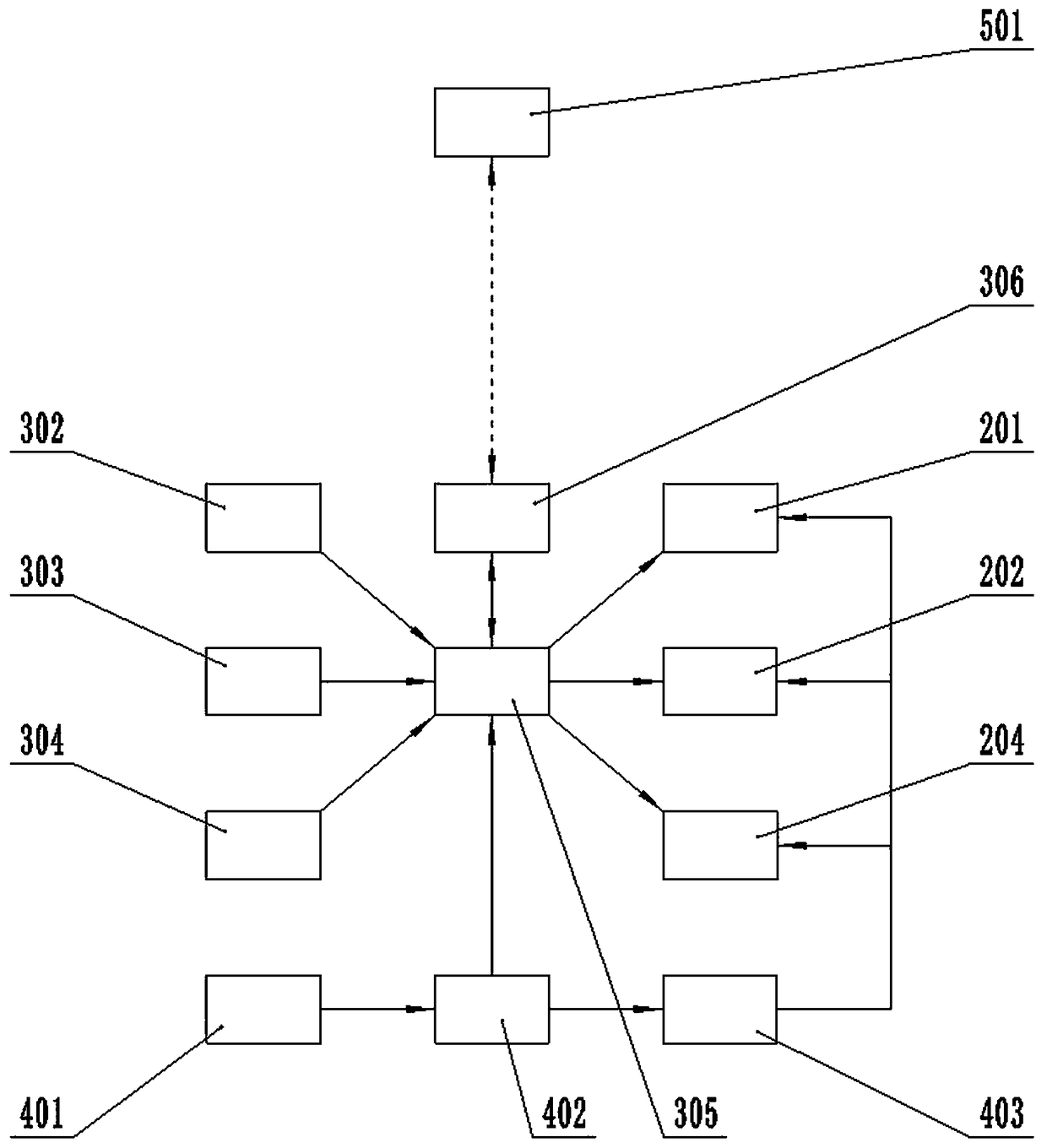

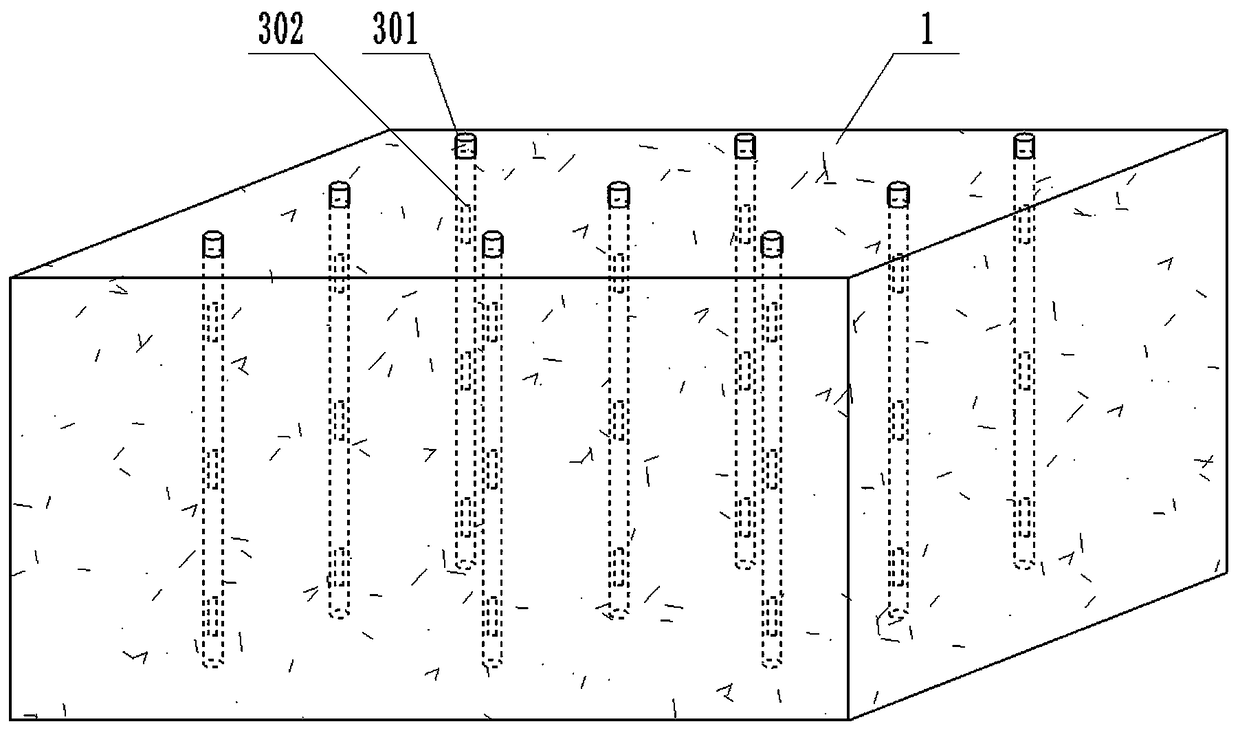

[0019] A large-volume concrete temperature control system, including a large-volume concrete pouring body 1 arranged in the inner cavity of a curing shed, an execution part, a control part, and a power supply part;

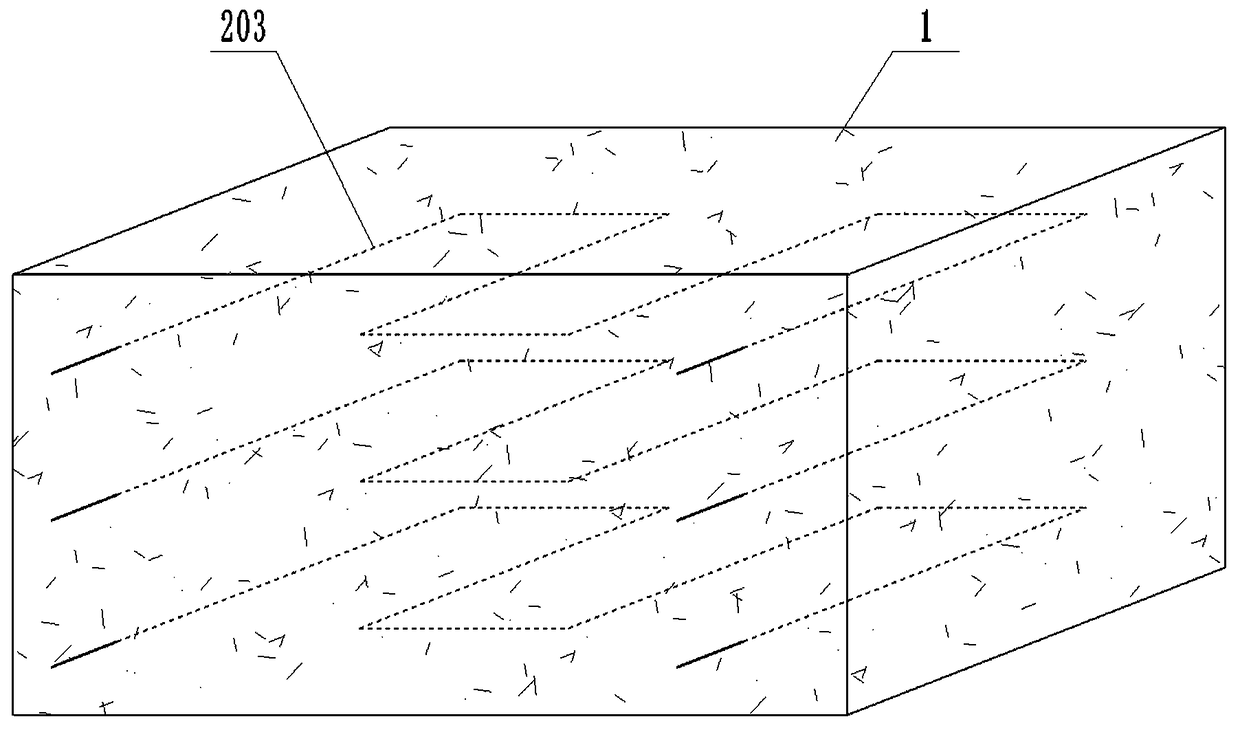

[0020] The execution part includes a water storage tank, a circulating pump 201, M electric valves 202, M cooling water pipes 203, and a humidifying device 204; M is a positive integer;

[0021] The water inlet of the circulating pump 201 is connected to the water storage tank; each cooling water pipe 203 is in the shape of a square wave; each cooling water pipe 203 is buried horizontally inside the large-volume concrete pouring body 1, and each cooling water pipe 203 is equally spaced and parallel from top to bottom arrangement; the water inlet and the water outlet of each cooling water pipe 203 all extend to the outside of the mass concrete pouring body 1; the water inlet of each cooling water pipe 203 communicates with the water outlet of the circulation pump 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com