Construction method of electronic chip plant waffle slab structure

A technology of electronic chips and waffle boards, which is applied to floors, building components, building structures, etc., can solve problems such as failure to meet FM certification, protracted process duration, difficulty in steel bar binding, etc., and achieve fast hanging operations or horizontal movement , The storage turnover space is small, and the effect of meeting the tight schedule of the factory building

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

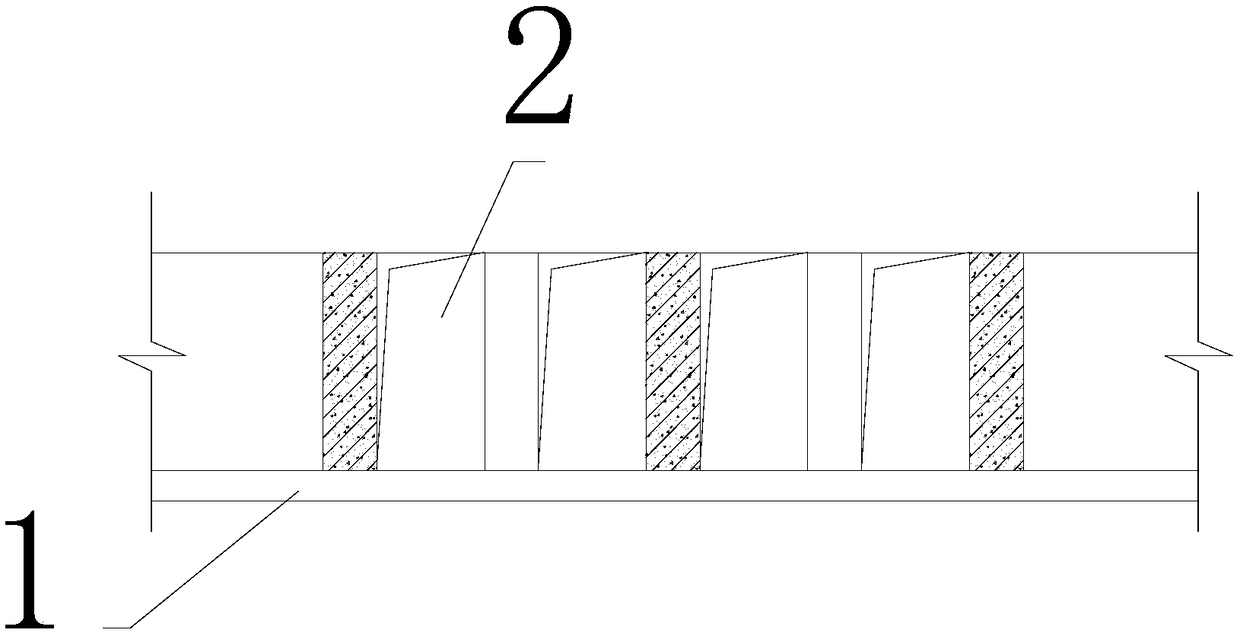

[0048] In this embodiment, the flatness of the bottom mold template 1 is adjusted before step C is performed, and the flatness of the bottom mold template 1 is calibrated simultaneously by measuring with a level instrument and drawing cross lines. In the construction process, the "double control" method of pulling the cross line and the level can not only meet the requirements of the area flatness detection, but also avoid human error and instrument error, which can not only ensure the construction efficiency, but also increase the reliability of the detection. Can significantly improve the flatness of the template. When pulling the cross line, use the theodolite to lead the axis control line to the wooden formwork surface, and check again, the error shall not be greater than 2mm, each axis is used as the control line, and the control line releases the vertical and horizontal axes at intervals of 4.8×4.8m.

[0049] Before step C, adjust the flatness of the template to make it ...

Embodiment 2

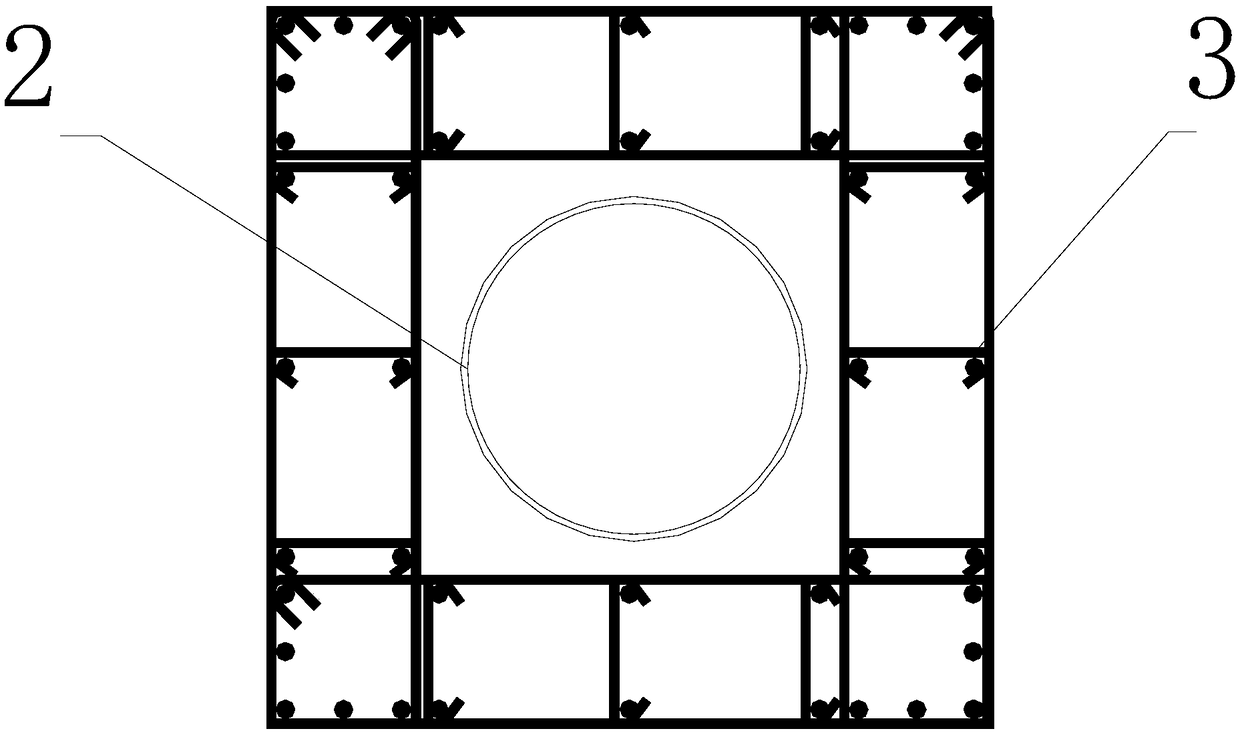

[0051] In this embodiment, the hole spacing of the waffle plate is 600mm, and the beams of 200mm×800mm are covered between the cylinder and the cylinder, with a height of 800mm. Therefore in the D step, tie the steel bars 3 overhead by the span, first bind the main beam steel bars 3 and the secondary beam bars, and then tie the waist bars. The site adopts vertical and horizontal span-based tying construction: place the lower cover of the Kistler tube 2ABS on the front line of tying, and then tie the main beam reinforcement 3 and the secondary beam reinforcement one by one in the sky, and then drop it into the mold after completion. After all the beams in the same direction are completed, use the same method to bind the beams in the other direction. The waist tendons are not tied for the time being, and the ribs will be tied after the beams are tied in place. In addition, during the binding construction of steel bars 3, the steel bars 3 should not be stacked together, and shou...

Embodiment 3

[0053] In this embodiment, the 2 shells of the Qishi cylinder are installed one by one, and one is successfully installed, and then the next one is installed. The aforementioned installation method can effectively avoid damage due to weak strength of the body wall of the Qishi cylinder 2. The gap between the cylinder body and the base is sealed with waterproof putty, and the gap with the upper cover is sealed with adhesive tape, which can effectively prevent the phenomenon of slurry leakage. The putty must be tightly sealed without cracking; the adhesive tape must be firmly pasted and there is no phenomenon that the outside is turned up.

[0054] After checking the position of steel bar 3 is correct, check that the Qishi cylinder 2 is not damaged or deformed, put the cylinder on the lower cover, tighten the screw and the chassis, install the upper cover, tighten the nuts, and fix it on the bottom formwork. Use the ruler, feeler gauge and level to check the elevation of the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com