Zirconia ceramic bearing ball

A technology of zirconia ceramics and bearing balls, applied in the field of bearing balls, can solve the problems of reducing the service life of bearing balls, high rolling load, and easy bearing damage, and achieves the effect of strong high temperature resistance and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

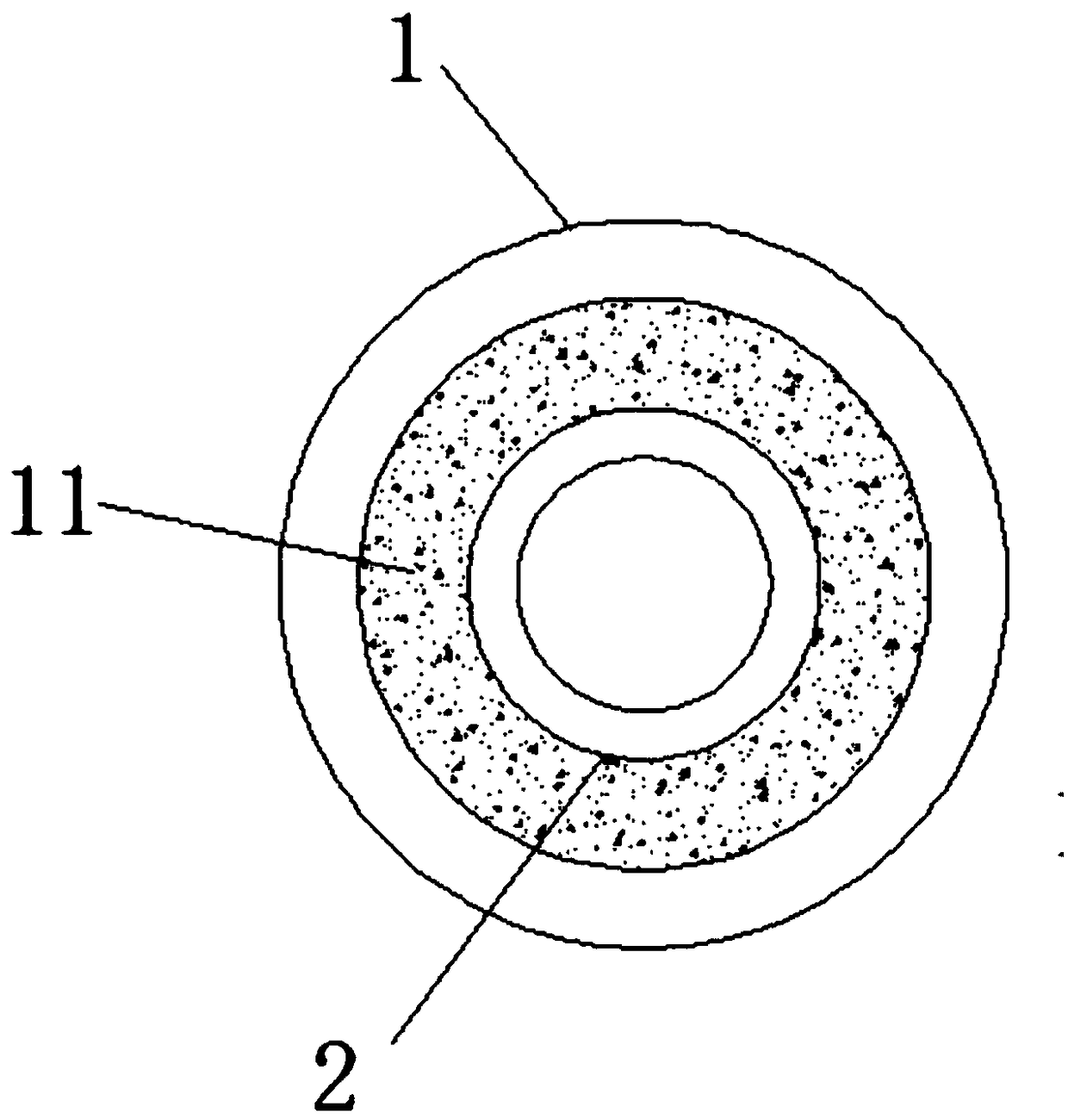

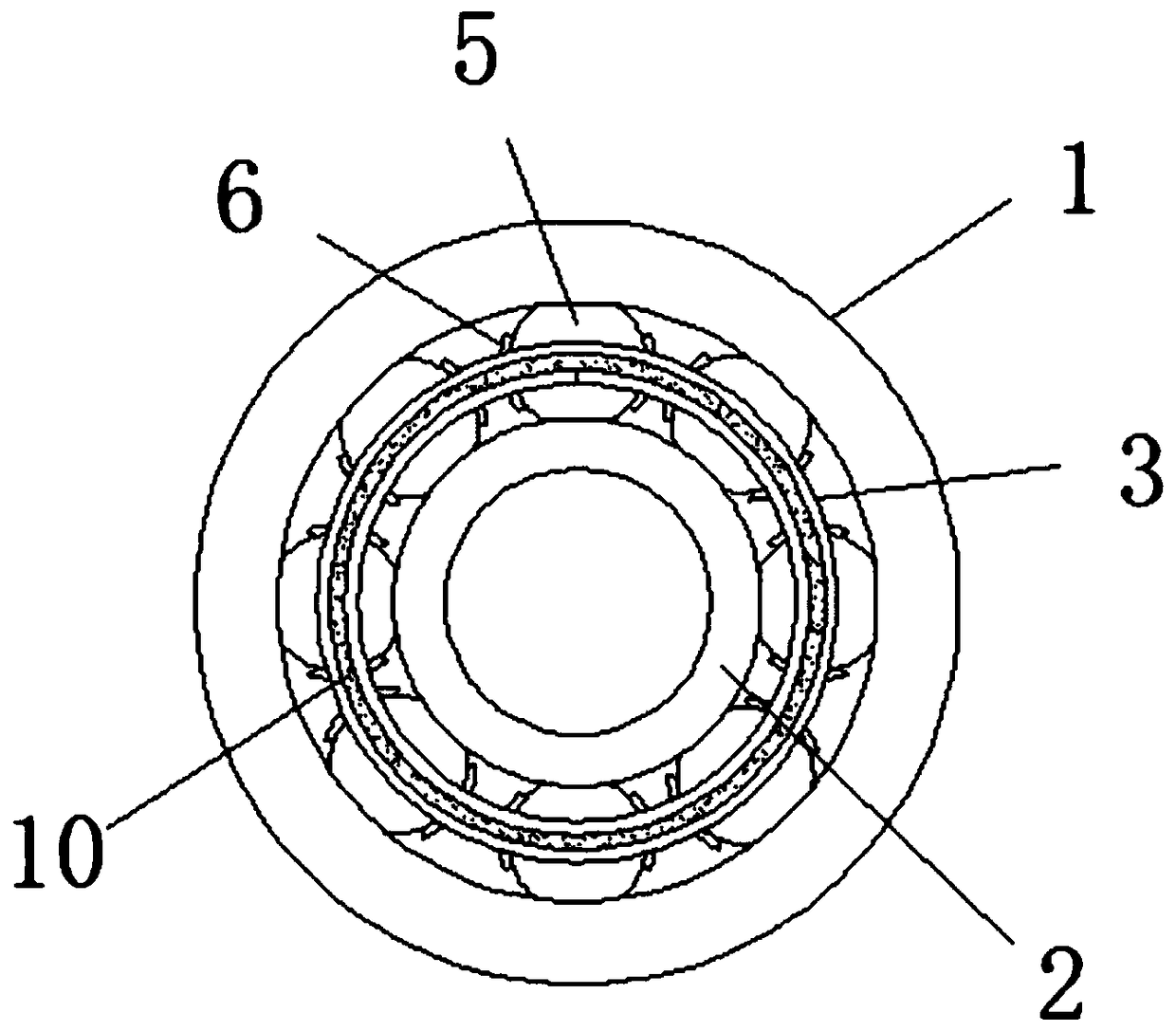

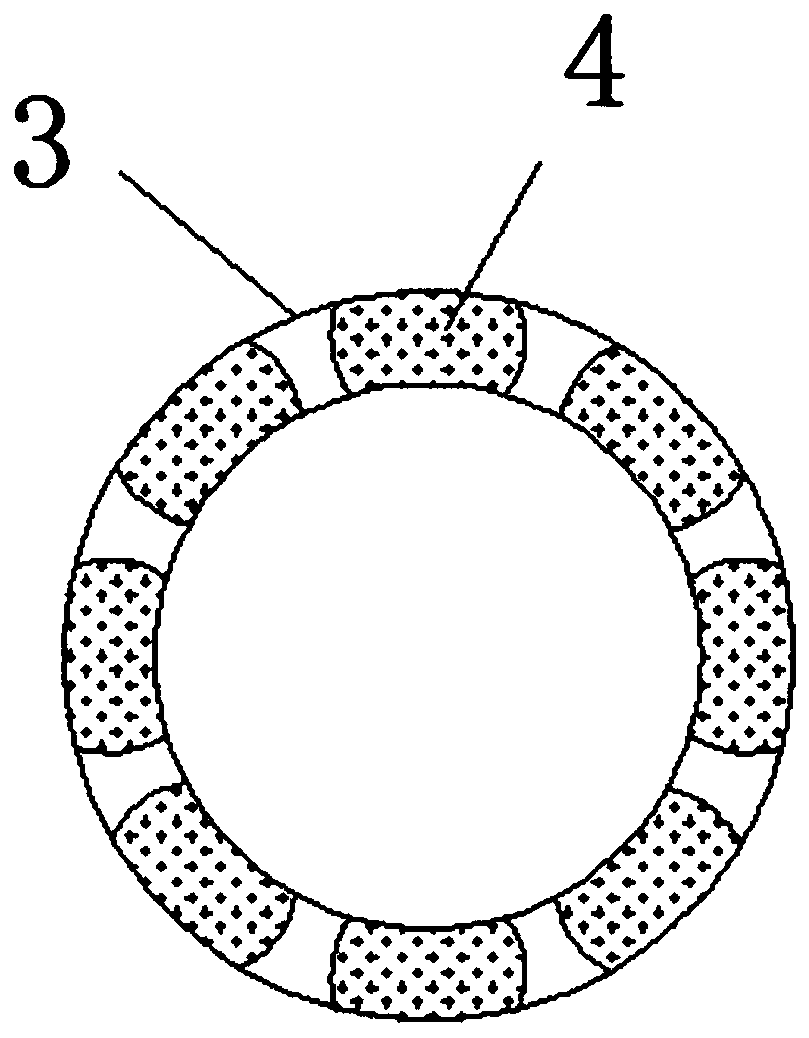

[0020] Such as Figure 1-4 As shown, a zirconia ceramic bearing ball includes an outer casing 1 and a rotating shaft 2, the outer casing 1 is movably connected with a rotating shaft 2, and a connecting piece 3 is movably connected between the outer casing 1 and the rotating shaft 2, and the connecting piece 3 A limit hole 4 is fixed inside, and a bearing ball 5 is movably connected to the inside of the limit hole 4, and the periphery of the bearing ball 5 is rotatably connected to a limit plate 6, and the inner wall of the outer jacket 1 is fixedly provided with a No. 1 rolling groove 7. The top of the rotating shaft 2 is fixed with the No. 2 rolling groove 8, and the inside of the No. 1 rolling groove 7 and the No. 2 rolling groove 8 are both fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com